China Low Volume Production Military Components Vacuum Casting Manufacturers, Suppliers, Factory

Our business has been focusing on brand strategy. Customers' pleasure is our best advertising. We also offer OEM company for Low Volume Production Military Components Vacuum Casting,Low Volume Production Military Products Vacuum Casting, Our main objectives are to provide our customers worldwide with good quality, competitive price, satisfied delivery and excellent services.

Low Volume Production Military Components Vacuum Casting, We can meet the various needs of customers at home and abroad. We welcome new and old customers to come to consult & negotiate with us. Your satisfaction is our motivation! Let us work together to write a brilliant new chapter!

Hot Products

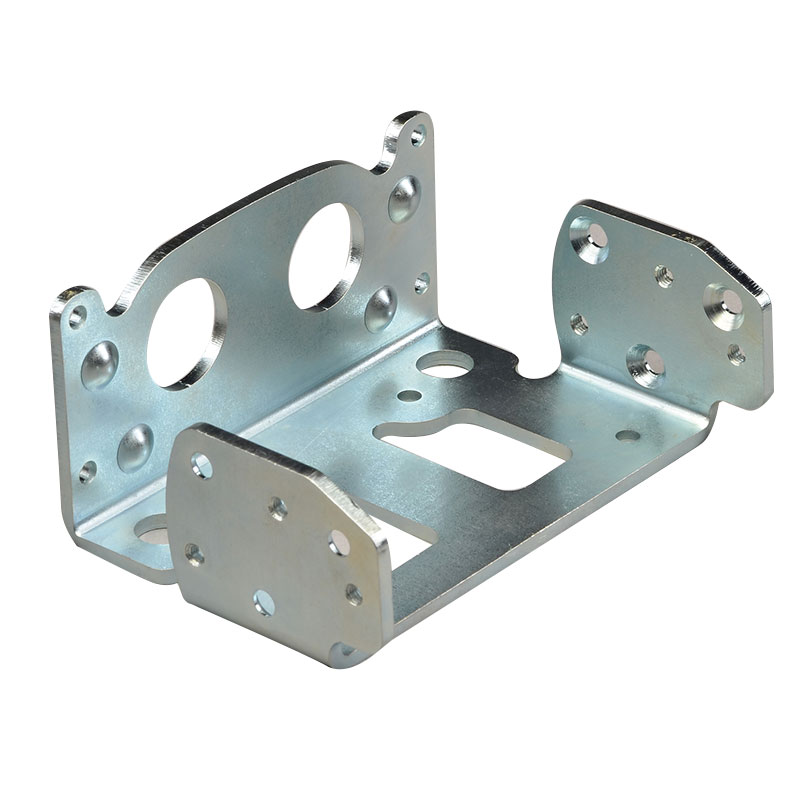

CNC Machining 4 axis Aluminium Anodizing Parts

CNC Machining 4 axis Aluminium Anodizing Parts:we are specialized manufacturers from China, Aluminum Block, Cnc Milling Machining Parts suppliers/factory, wholesale high-quality products of Aluminum Cnc Machining Parts R & D and manufacturing, we have the perfect after-sales service and technical support. Look forward to your cooperation!Auto Throttle Control Shafts Parts CNC Machining

The following is about Auto Throttle Control Shafts Parts CNC Machining.Medical Glucose Meter Device Rapid Prototypes

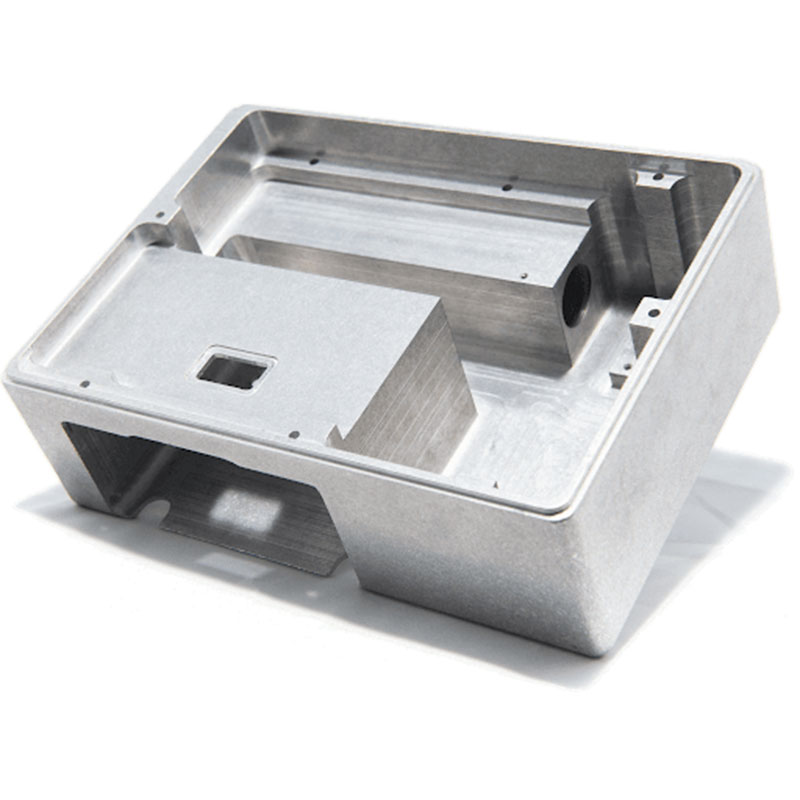

We offer a complete turnkey solution for creating master patterns and cast copies based on your CAD designs. We not only make high-quality molds but we also offer a full line of finishing services including painting, sanding, pad printing and more. We’ll help you create parts for showroom quality display models, engineering test samples, crowdfunding campaigns and more.The following is about Medical Glucose Meter Device Rapid Prototypes.Auto Parts Powder Coating Rapid Prototype

Powder Coating is most commonly used in the industrial sector for both (Low Volume and High Volume) Mass Production Factories such as CNC Machine Shops and Sheet Metal Fabrication Facilities. The Powder Coating material is a composite mixture of fine powderized paint pigments and fine powderized plastic particles. The fine powderized plastic particles are comprised of either (thermoplastics or thermoset plastics) such as Polyester and Epoxy. When discharged through the Powder Coat Paint Gun, the particles are ionized via an electrical coil. The positively charged ions assist the powder in the coating process as it is attracted to the negatively charged part.The following is about Auto Parts Powder Coating Rapid Prototype.Servo Motor Shaft Aerospace Parts CNC Turning

Servo Motor Shaft is one of the important parts of the motor. It acts as a link between the electromechanical energy conversion between the motor and the device, supporting the rotating parts, transmitting torque and determining the relative position of the rotating parts to the stator.The following is about Servo Motor Shaft Aerospace Parts CNC Turning.Auto Solid Valve Housing Parts CNC Machining

Valve Housing is a key auto valve fitting to assist valve to control the flow of air or liquid through the tube. If your valve in a corrosive environment and the valve housing can't resist corrosion, it will reduce the durability.The inappropriate valve housing and valve fittings will influence valve performance as well.

So, choosing the right valve housing and valve seal material is critical to the running of an automobile valve and the whole system. The core characteristics, materials, properties of the automotive valve housing and application environment should be taken into consideration, including temperature, corrosion possibility, wear characteristics and pressure.The following is about auto solid valve housing parts CNC machining.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy