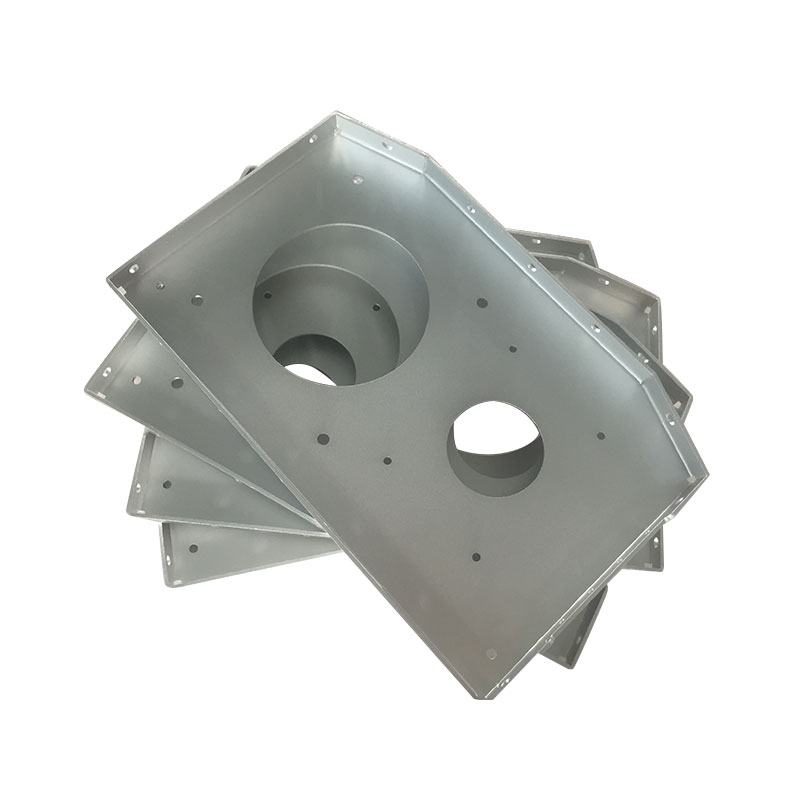

China Mechanical Liquid Urethane Resin Components Vacuum Casting Manufacturers, Suppliers, Factory

No matter new customer or old customer, We believe in long term and trusted relationship for Mechanical Liquid Urethane Resin Components Vacuum Casting,Mechanical Liquid Urethane Resin Products Vacuum Casting, Prospects first! Whatever you require, we should do our utmost to help you. We warmly welcome clients from all around the globe to cooperate with us for mutual enhancement.

Mechanical Liquid Urethane Resin Components Vacuum Casting, The best and original quality for spare parts is a most important factor for transportation. We may stick on supplying original and good quality parts even a little profit earned. God will bless us to do kindness business forever.

Hot Products

Steel Aerospace Parts Rapid Prototype

Rapid prototype castings are fully functioning parts with the same strength and metallurgical properties as traditionally investment cast parts. However, they carry the added advantage of substituting injected wax patterns with 3-D printed patterns, resulting in a quick and relatively low-cost alternative for those who only need a limited number of parts.

Investment casting using rapid prototypes is a reliable means to quickly produce metal castings while in the preliminary design phases of an investment casting project. This allows you to test out a sample design, which can help avoid expensive tooling changes. Oftentimes, rapid prototype castings are less costly and time-consuming than the process of machining prototypes out of bar stock or producing prototypes through weldments.The following is about Steel Aerospace Parts Rapid Prototype.Low Volume Production Military Parts Vacuum Casting

Vacuum casting is a low-cost but reliable method for making a small number of high-quality prototypes based on a master model. This method is ideal for rapid prototyping used in engineering testing, proof-of-concept and display demos. On superior prototype, we have a dedicated team of mold makers who are experts at creating vacuum casting molds for many years.The following is about Low Volume Production Military Parts Vacuum Casting.Auto Parts Vacuum Urethane Casting

Vacuum casting technology offers a wide variety of materials to facilitate the creation of cast urethane parts, typically for functional test, pre-production evaluation and low volume production. Cast auto urethane parts are quick and inexpensive without the need to invest any metal tooling when quantities are only dozens of short runs, and can be delivered within weeks in most instances. The following is about Auto Parts Vacuum Urethane Casting.Aircraft Seat Frame Parts Rapid Prototypes

Innovative prototypes from aerospace engineering workshops are already in flight today. Rapid prototyping is already being used to produce specific aircraft interior components such as air ducts, armrests, seat frames end caps, seat framework and wall panels. Prototyping will be an integral piece of the manufacturing and new part development processes for years to come. The prototypes from aerospace engineering will without a doubt be at the center of space exploration as well as the coming transportation revolution.The following is about Aircraft Seat Frame Parts Rapid Prototypes.Car Engine Housing Parts CNC Machining

For some automotive components, CNC machining, which involves carrying out tasks like drilling and boring with computer control and automation, now serves as a favourable option for both prototyping and production.

CNC machines turn a digital file into a sequence computer instruction, which are sent to a motorised tool such as a drill, lathe or mill. The tool turns a block of material into a finished product by cutting it in the appropriate places, providing much greater accuracy than conventional machining.The following is about car engine housing parts CNC machining.Auto Solid Valve Housing Parts CNC Machining

Valve Housing is a key auto valve fitting to assist valve to control the flow of air or liquid through the tube. If your valve in a corrosive environment and the valve housing can't resist corrosion, it will reduce the durability.The inappropriate valve housing and valve fittings will influence valve performance as well.

So, choosing the right valve housing and valve seal material is critical to the running of an automobile valve and the whole system. The core characteristics, materials, properties of the automotive valve housing and application environment should be taken into consideration, including temperature, corrosion possibility, wear characteristics and pressure.The following is about auto solid valve housing parts CNC machining.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy