China Aerospace Couplers Products CNC Turning Manufacturers, Suppliers, Factory

We are commitment to offer the competitive price ,outstanding products quality, as well as fast delivery for Aerospace Couplers Products CNC Turning,Aerospace Couplers Components CNC Turning, We have ISO 9001 Certification and qualified this product or service .in excess of 16 years experiences in manufacturing and designing, so our goods featured with very best high-quality and aggressive rate. Welcome cooperation with us!

Aerospace Couplers Products CNC Turning, Customer's satisfaction is always our quest, creating value for customers is always our duty, a long term mutual-beneficial business relationship is what we're doing for. We're an absolutely reliable partner in your case in China. Of course, other services, like consulting, can be offered too.

Hot Products

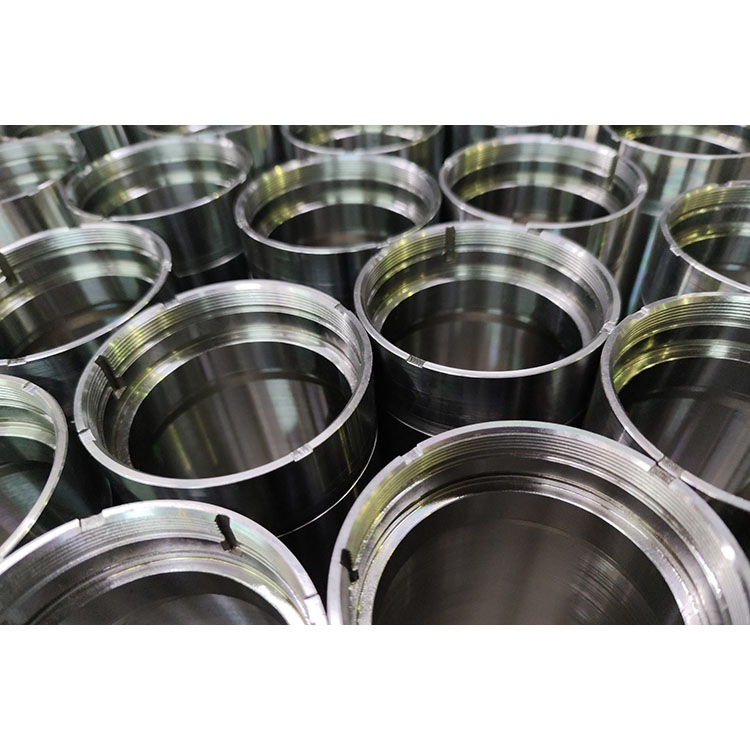

Servo Motor Shaft Aerospace Parts CNC Turning

Servo Motor Shaft is one of the important parts of the motor. It acts as a link between the electromechanical energy conversion between the motor and the device, supporting the rotating parts, transmitting torque and determining the relative position of the rotating parts to the stator.The following is about Servo Motor Shaft Aerospace Parts CNC Turning.3D Printing Electronic Products Rapid Prototypes

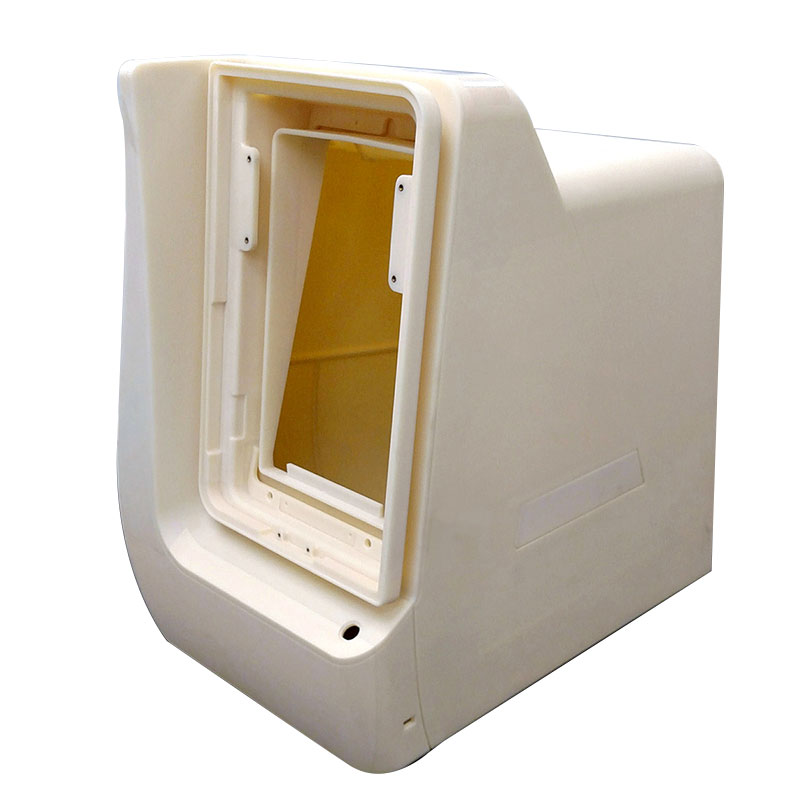

Consumers have come to expect periodic releases of ever-more advanced electronics. From smartphones to smart home systems and wearables, new consumer products require significant evaluation and testing before they hit the market. Before moving to mass manufacturing, these new products require rigorous testing for quality, functionality, and user experience.

With new consumer product upgrade and release cycles becoming tighter, electronics designers need a solution that helps reduce the time involved in each R&D and prototyping cycle. By far, the most time-consuming and least productive portion of R&D is repetitive design, build, and test cycles.

Rapid prototyping with traditional manufacturing processes is anything but fast, so designers need a real solution for true rapid prototyping. This illustrates the value of 3D printing in consumer electronics development and prototyping; designers can quickly create fully-functional electronics in a matter of hours rather than days, and this can be done in-house. Designers can innovate more often, quickly test functionality, and implement redesigns before manufacturing at scale. The following is about 3D Printing Electronic Products Rapid Prototypes.Indirectly Human Medical Device Parts CNC Machining

The following is about Indirectly Human Medical Device Parts CNC Machining.Aluminium Anodizing Military Parts CNC Turning

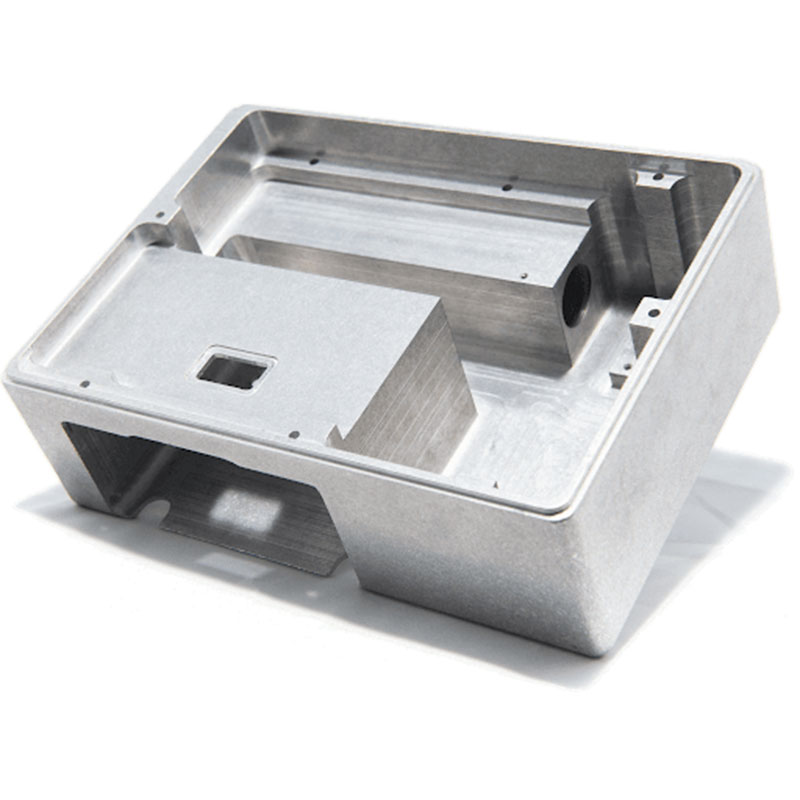

The Aluminium Anodizing Military Parts CNC Turning provided by Shbury are made of 6061 aluminum using CNC milling, turning and drilling machines for a variety of equipment. Our precision machining services have the ability to upgrade your current design to solid piece with the exact specification, also ensure consistent quality and short lead time for your custom prototype and low/high volume production parts. Black anodizing process is applied on the Aluminium Anodizing Military Parts CNC Turning, which increases the thickness of the natural oxide layer on the surface of aluminum components, and improves its corrosion and wear resistance. Our aluminum anodizing services provide an anodized aluminum coating that meets industry standards. Other colors can be dyed during the process. More surface treatment services available to give your aluminum drilling parts or milling parts a smooth surface finish.Brass Inserts Plastic Electronic Products Vacuum Casting

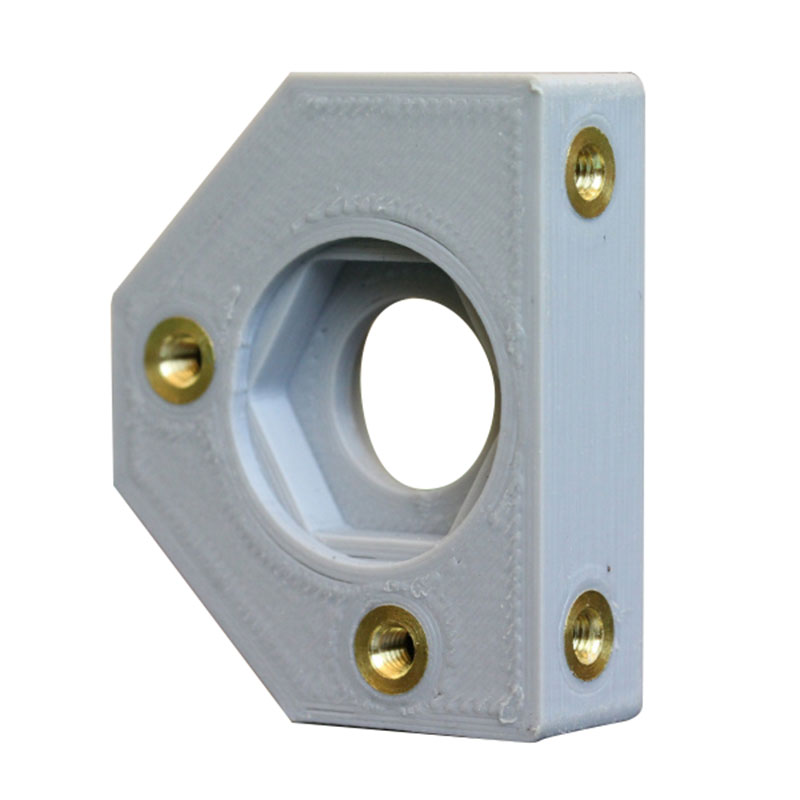

Shbury has a fully equipped Vacuum Casting suite with multiple vacuum casting machines. We also have 3D printing facilities which are used for producing the master pattern. For best quality, we use high definition SLA models.The following is about Brass Inserts Plastic Electronic Products Vacuum Casting.Car Engine Housing Parts CNC Machining

For some automotive components, CNC machining, which involves carrying out tasks like drilling and boring with computer control and automation, now serves as a favourable option for both prototyping and production.

CNC machines turn a digital file into a sequence computer instruction, which are sent to a motorised tool such as a drill, lathe or mill. The tool turns a block of material into a finished product by cutting it in the appropriate places, providing much greater accuracy than conventional machining.The following is about car engine housing parts CNC machining.