China Indirectly Human Medical Device Components CNC Machining Manufacturers, Suppliers, Factory

While in the past few years, our organization absorbed and digested sophisticated technologies both equally at home and abroad. Meanwhile, our corporation staffs a group of experts devoted to your advancement of Indirectly Human Medical Device Components CNC Machining,Indirectly Human Medical Device Parts CNC Milling,Indirectly Human Medical Device Products CNC Machining, As an expert specialized with this field, we have been committed to solving any problem of significant temperature protection for users.

Indirectly Human Medical Device Components CNC Machining, Our factory is equipped with complete facility in 10000 square meters, which makes us be able to satisfy the producing and sales for most auto part solutions. Our advantage is full category, high quality and competitive price! Based on that, our goods win a high admiration both at home and abroad.

Hot Products

Electronic Hookah Nozzle Products CNC Turning

The following is about Electronic Hookah Nozzle Products CNC Turning.Metal Precision Mechanical Parts CNC Machining

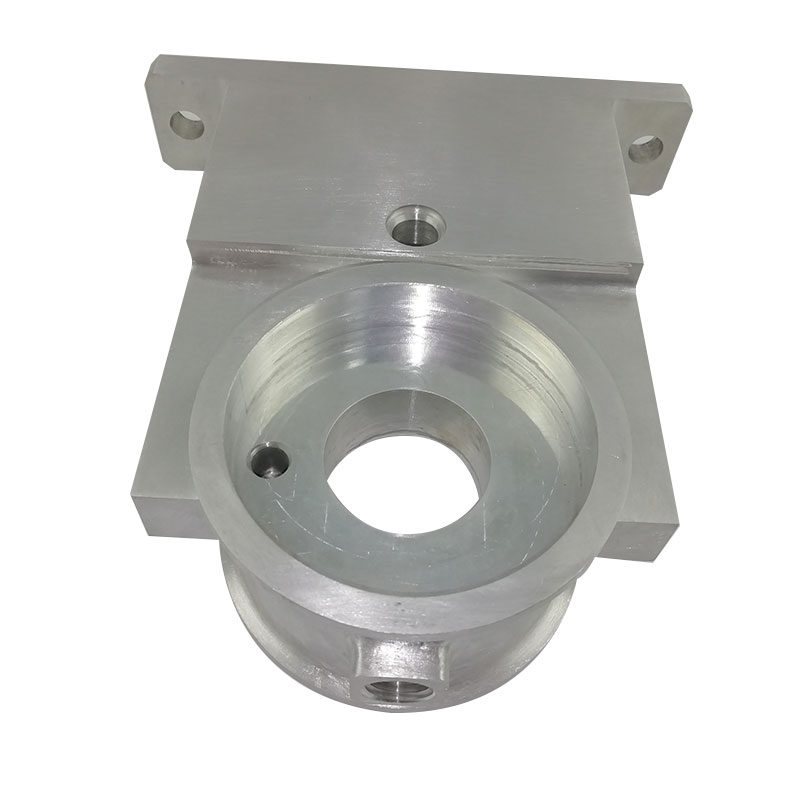

Firstly, parts for robotic applications often have a requirement to be strong, tough and lightweight. Materials such as aluminium have ideal characteristics and can easily be machined using CNC Machining.

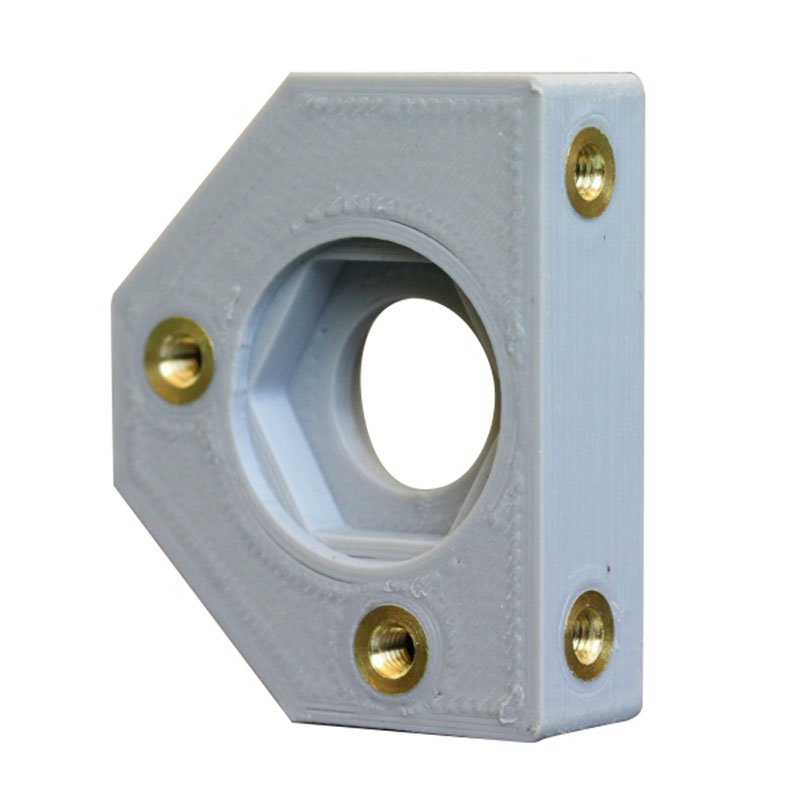

Similarly POM (also known as Delrin and Acetal) is commonly used for robotic mechanical cnc machining parts. Easy to machine, it is known for its low friction, high stiffness and superior dimensional stability. As a low-cost plastic, it is also a very economical option.The following is about metal precision mechanical parts CNC machining.Auto Throttle Control Shafts Parts CNC Machining

The following is about Auto Throttle Control Shafts Parts CNC Machining.Eco-friendly Low Price CNC Machining Aluminum anodizing Plate Parts

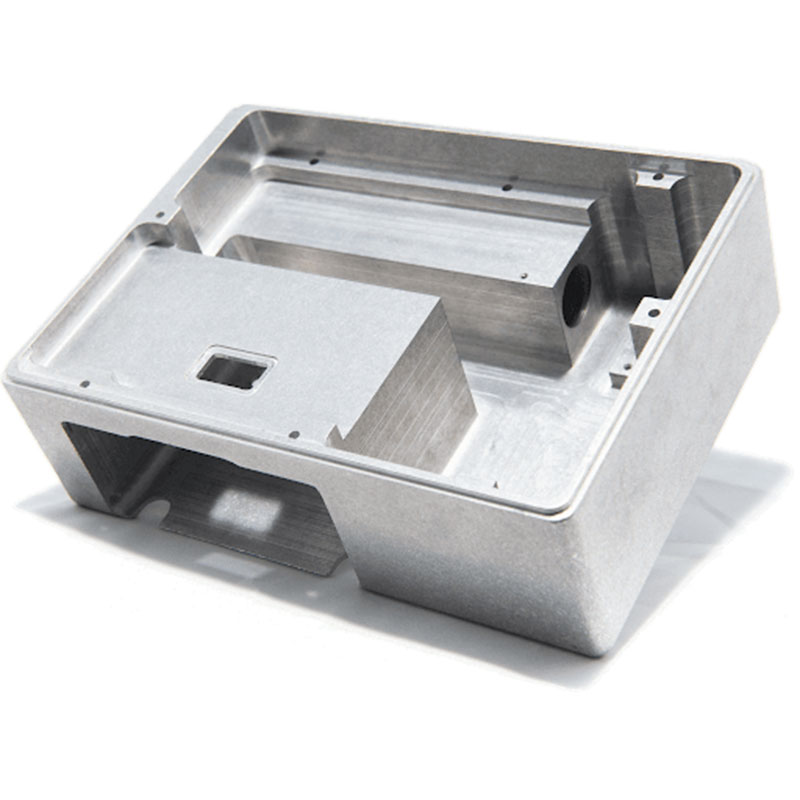

Eco-friendly Low Price CNC Machining Aluminum anodizing Plate Parts:If you need aluminum parts cnc machined we are one of the most capable and affordable sources specializing in manufacturing precision machined parts on advanced cnc machines. With rich knowledge and experience, our cnc machine shop is able to produce parts that require innovative tooling and fixturing in a timely manner with competitive price. We do cnc machining on 4,5 axis all kinds of aluminum with 6061 and 7075 being the most used.Polishing Cast Bronze Brass Copper Casting

China Polishing Cast Bronze Brass Copper Casting Factory Directly Supply. Guoye Optoelectronics is Polishing Cast Bronze Brass Copper Casting manufacturer and supplier in China.Mechanical Connectors Parts CNC Turning

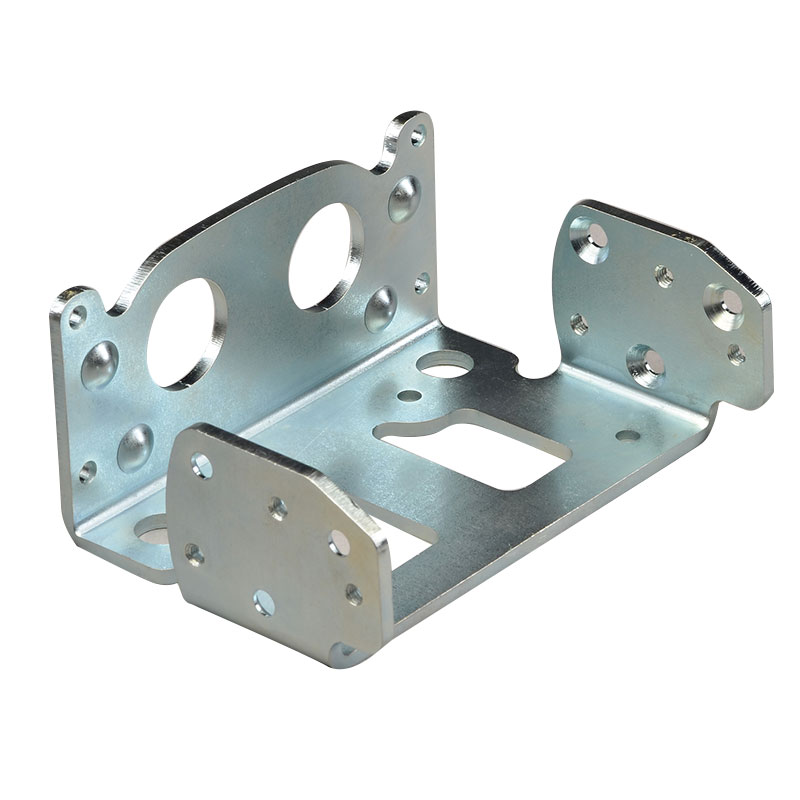

Mechanical Connectors Parts, including the Joint Connector Nuts, Joint Connector Blots, Joint Connector Screws, are mechanical connectors which used to link between two structures, connect parts or components together similar to fasteners.The following is about Mechanical Connectors Parts CNC Turning.