China Airframe Plastic Products Vacuum Casting Manufacturers, Suppliers, Factory

We emphasize enhancement and introduce new solutions into the market just about every year for Airframe Plastic Products Vacuum Casting,Airframe Plastic Components Vacuum Casting, We generally hold the philosophy of win-win, and build long-term cooperation partnership with clients from throughout the earth.We believe that our growth base on customer's achievements, credit history is our lifetime.

Airframe Plastic Products Vacuum Casting, We set a strict quality control system. We now have return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products. You should feel free to contact us for further information and we will present you competitive price list then.

Hot Products

Auto Flanges Fuser Rollers Parts CNC Turning

With the aid of our diligent professionals, we are engaged in manufacturing and supplying Turning Flange. These flanges are available for the clients in different sizes and specification. Precision turned from raw metal using high-end cnc machines, these flanges are provided to a large number of customers ranging from engineering to automotive industries Our offered flanges are quality tested with the aid of diligent analysts before the final dispatch. The Turning Flange is provided at the specified place on time.The following is about Auto Flanges Fuser Rollers Parts CNC Turning.Medical Infusion Pump Housing Rapid Prototypes

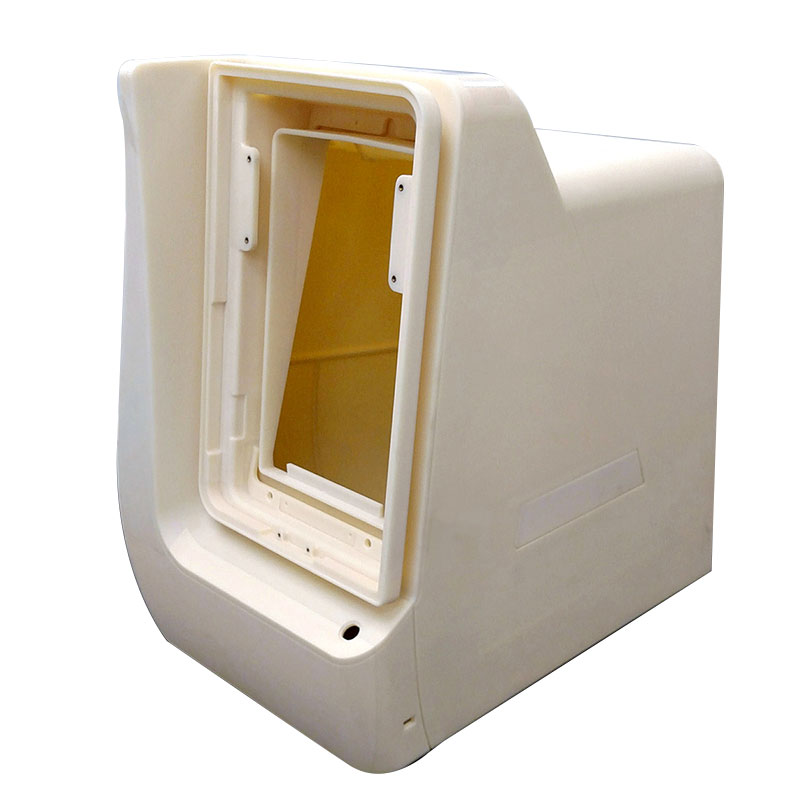

We offer a complete turnkey solution for creating master patterns and cast copies based on your CAD designs. We not only make high-quality molds but we also offer a full line of finishing services including painting, sanding, pad printing and more. We’ll help you create parts for showroom quality display models, engineering test samples, crowdfunding campaigns and more.The following is about Medical Infusion Pump Housing Rapid Prototypes.Smart Mechanical Parts Vacuum Casting

Vacuum casting services is a type of rapid prototyping technology. It is used for producing a photocopy of the original product in a vacuum state, and then use (PU, transparent PU, POM-like, ABS) and other materials to cast the same copy as the product prototype.

Vacuum casting services are suitable for the customer who requires several sets of rapid prototype parts, which significantly reduces the cost and development time. The following is about Smart Mechanical Parts Vacuum Casting.Aircraft Seat Frame Parts Rapid Prototypes

Innovative prototypes from aerospace engineering workshops are already in flight today. Rapid prototyping is already being used to produce specific aircraft interior components such as air ducts, armrests, seat frames end caps, seat framework and wall panels. Prototyping will be an integral piece of the manufacturing and new part development processes for years to come. The prototypes from aerospace engineering will without a doubt be at the center of space exploration as well as the coming transportation revolution.The following is about Aircraft Seat Frame Parts Rapid Prototypes.Aluminium Electronic Products Rapid Prototypes

Aluminum alloy is widely used in the industry. It is low in density, high in strength, excellent in elasticity, processability and welding characteristics. It also features good corrosion resistance, high toughness, and deformation after manufacturing.

Aluminum alloy molding can help discover potential flaws early in the product development stage, saving money in the long-run and minimizing production times. Aluminum alloy rapid prototype helps generate accurate product test data.The following is about Aluminium Electronic Products Rapid Prototypes.Auto Waterproof Rubber Parts Vacuum Casting

We frequently vacuum cast rubber auto waterproof parts for custom seals and gaskets, but there is a wide variety of hardness’s available. Anything from the softness of a jelly baby right through to the hardness of a car tyre (Shore 30 – 95A hardness) The level of detail matches that of an injection moulded part.The following is about Auto Waterproof Rubber Parts Vacuum Casting.