China Auto Track Hubs Frame Components CNC Machining Manufacturers, Suppliers, Factory

With our superb management, potent technical capability and strict quality command procedure, we go on to provide our shoppers with trustworthy high-quality, reasonable costs and outstanding services. We goal at becoming considered one of your most trustworthy partners and earning your pleasure for Auto Track Hubs Frame Components CNC Machining,Auto Track Hubs Frame Parts CNC Milling,Auto Track Hubs Frame Products CNC Machining, We invites both you and your enterprise to thrive along with us and share a vibrant long term in global sector.

Auto Track Hubs Frame Components CNC Machining, We are going to supply much better items with diversified designs and professional services. We sincerely welcome friends from over the world to visit our company and cooperate with us on the basis of long-term and mutual benefits.

Hot Products

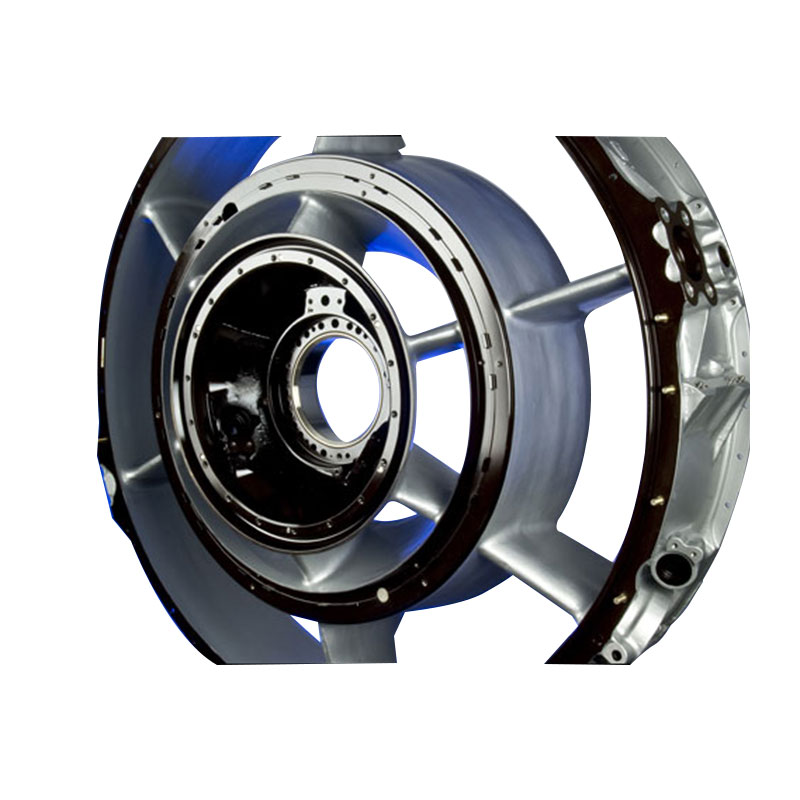

Auto Track Hubs Frame Parts CNC Machining

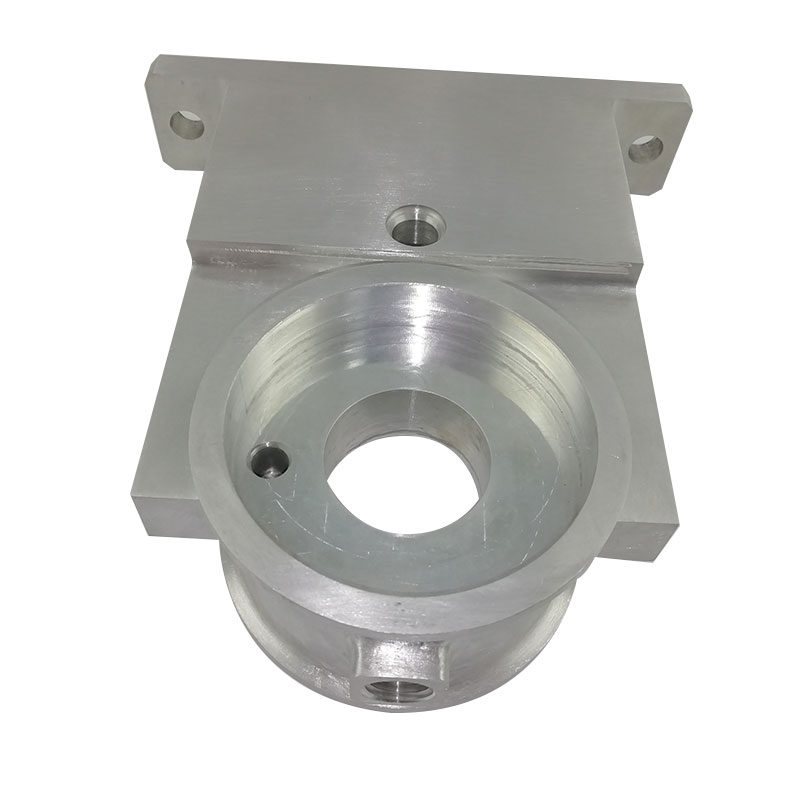

Simple to complex part turning and milling machining services for Automotive industries. For automotive parts and parts machining,Shbury offers the highest degree of OEM service with a basis of 10+ years experience serving the automotive industry. Our automotive precision shop and experts deliver confidence. We have perfected the art of producing large component volumes with complete Shbury reliability, backed by the quality and long-term reliability our customers expect.The following is about auto track hubs frame parts CNC machining.Electronic Bushes Products CNC Turning

The following is about Electronic Bushes Products CNC Turning.Office Industry Parts Rapid Prototypes

Rapid prototyping uses 3D computer aided design (CAD) and manufacturing processes (typically additive manufacturing) to quickly develop 3D parts, models, or assemblies for research and development and/or product testing.

The use of rapid prototyping techniques allows design teams to develop multiple iterations of a design prototype without the added cost and time using traditional manufacturing and design techniques.The following is about Office Industry Parts Rapid Prototypes.Auto Parts Powder Coating Rapid Prototype

Powder Coating is most commonly used in the industrial sector for both (Low Volume and High Volume) Mass Production Factories such as CNC Machine Shops and Sheet Metal Fabrication Facilities. The Powder Coating material is a composite mixture of fine powderized paint pigments and fine powderized plastic particles. The fine powderized plastic particles are comprised of either (thermoplastics or thermoset plastics) such as Polyester and Epoxy. When discharged through the Powder Coat Paint Gun, the particles are ionized via an electrical coil. The positively charged ions assist the powder in the coating process as it is attracted to the negatively charged part.The following is about Auto Parts Powder Coating Rapid Prototype.Galvanized Steel Sheet Metal Bending Parts

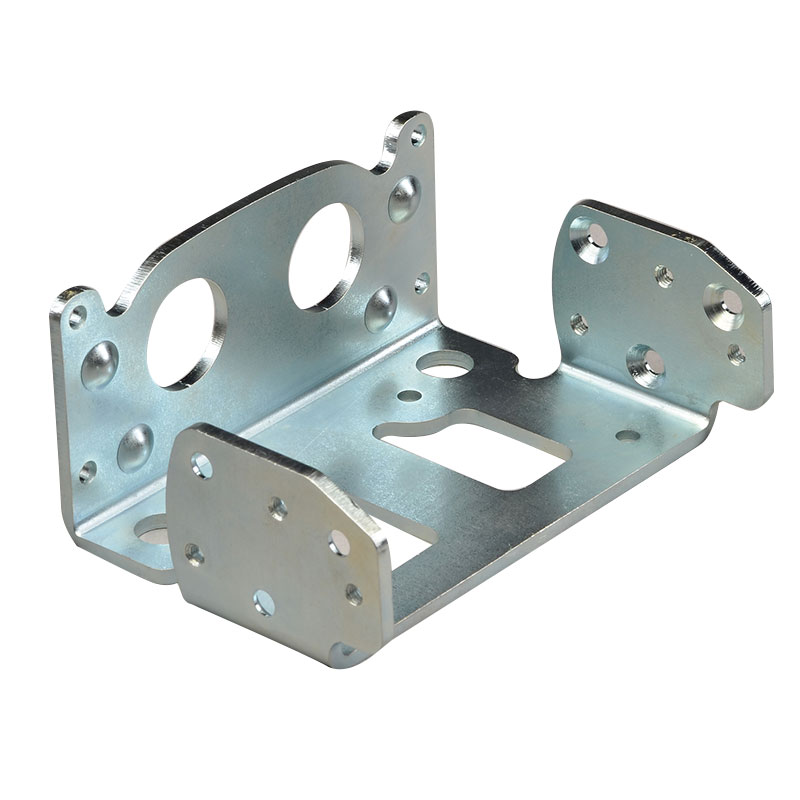

Galvanized steel sheet metal bending parts or galvanealed steel, which is galvanized then annealed.

Galvanization is the process of applying a protective zinc coating to steel in order to prevent rust and corrosion. Annealing is a heat treatment process that alters the microstructure of a material to change its mechanical or electrical properties, typically reducing the hardness and increasing the ductility for easier fabrication.Auminium Sheet Metal Stamping Parts

Take your custom products to the next level with high-grade aluminum sheet metal stampings parts from Shbury. We’re an aluminum stamping factory that will support your vision by providing custom aluminum parts tailored to your unique project. Thanks to our industry-leading in-house tooling capabilities and favorable lead times, you can trust that we will deliver on time and on budget.

At Shbury we don’t take a cookie-cutter approach to any of our partnerships. Our tooling is completely customized and we’re able to meet your exact manufacturing needs through extensive list of value added services.The following is about auminium sheet metal stamping parts.