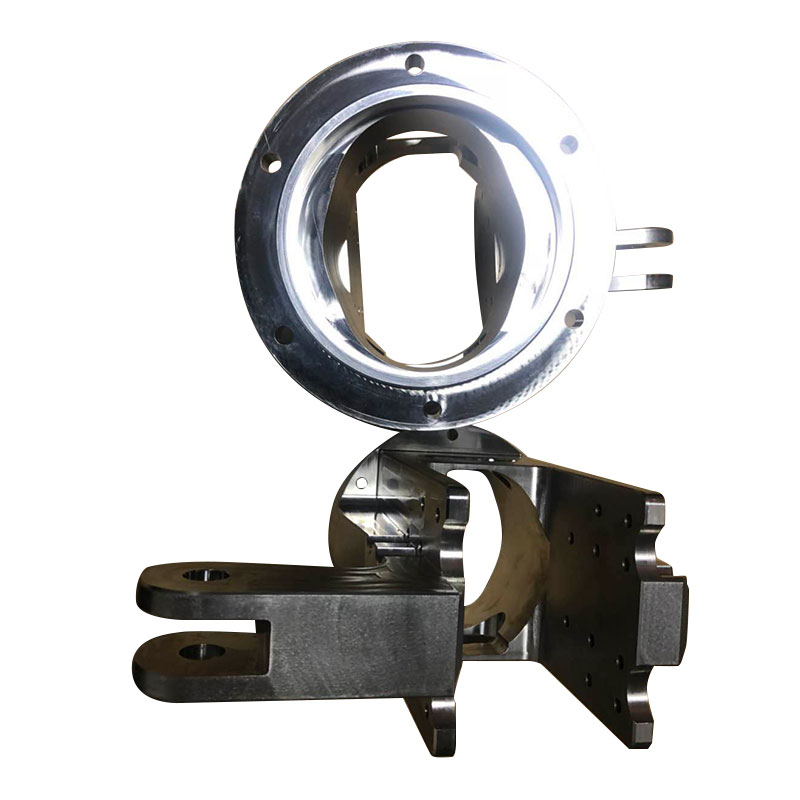

Auto Parts Rapid Prototypes

The design process for new or improved automotive parts and assemblies includes the important step of producing, examining, and testing a physical prototype to observe how the product performs and note where it can be improved. Automotive engineers have always used prototypes in their work for iterative testing, but with rapid prototyping, this process can be done faster, more efficiently, and at a lower cost. Engineers and designers can benefit from having an automotive prototype to sample sizing and test for form, fit, feel, and function.

Auto parts rapid prototypes manufacturing ca be achieve by 3d printing, cnc machining, assembly. Additionally, prototyping and production for automotive applications is not limited to small parts; multiple components can be joined to create very large items.

- View as

Auto Parts Powder Coating Rapid Prototype

Powder Coating is most commonly used in the industrial sector for both (Low Volume and High Volume) Mass Production Factories such as CNC Machine Shops and Sheet Metal Fabrication Facilities. The Powder Coating material is a composite mixture of fine powderized paint pigments and fine powderized plastic particles. The fine powderized plastic particles are comprised of either (thermoplastics or thermoset plastics) such as Polyester and Epoxy. When discharged through the Powder Coat Paint Gun, the particles are ionized via an electrical coil. The positively charged ions assist the powder in the coating process as it is attracted to the negatively charged part.The following is about Auto Parts Powder Coating Rapid Prototype.

Read MoreSend InquiryPEEK Auto Parts Rapid Prototyping

The following is about PEEK Auto Parts Rapid Prototyping.

Read MoreSend InquiryAuto Parts Heat Treatment Rapid Prototypes

Heat treatments can be applied to metal alloys throughout the manufacturing process. For CNC machined parts, heat treatments are typically applied either:

Before CNC machining: When a standardized grade of a metal alloy is requested that is readily available, the CNC service provider will machine the parts directly from that stock material. This is often the best option for reducing lead times.

After CNC machining: Some heat treatments significantly increase the hardness of the material or are used as a finishing step after forming. In these cases, the heat treatment is applied after CNC machining, as high hardness reduces the machinability of a material. For example, this is standard practice when CNC machining tool steel parts.The following is about Auto Parts Heat Treatment Rapid Prototypes.

Laser Cutting Auto Parts Rapid Prototypes

Shbury offers rapid prototyping services for laser cut parts. Laser technology allows us to manufacture parts quickly and cost-effectively, allowing us to provide your team with a precision part prototype quickly and cost-effectively. Using the latest CNC technology, we can use your CAD drawings to produce a part without the delays required to design and manufacture tooling.The following is about Laser Cutting Auto Parts Rapid Prototypes.

Read MoreSend Inquiry