China Aluminium Aerospace Parts Products Machining Manufacturers, Suppliers, Factory

"Control the standard by the details, show the energy by quality". Our business has strived to establish a really efficient and stable personnel team and explored an effective high quality manage process for Aluminium Aerospace Parts Products Machining,Aluminium Aerospace Parts CNC Milling,Aluminium Aerospace Parts Components Machining, We're going to empower people by communicating and listening, Setting an example to others and learning from experience.

Aluminium Aerospace Parts Products Machining, We maintain long-term efforts and self-criticism, which helps us and improvement constantly. We strive to improve customer efficiency to save costs for customers. We do our best to improve the quality of product. We are going to not live up to the historic opportunity of the times.

Hot Products

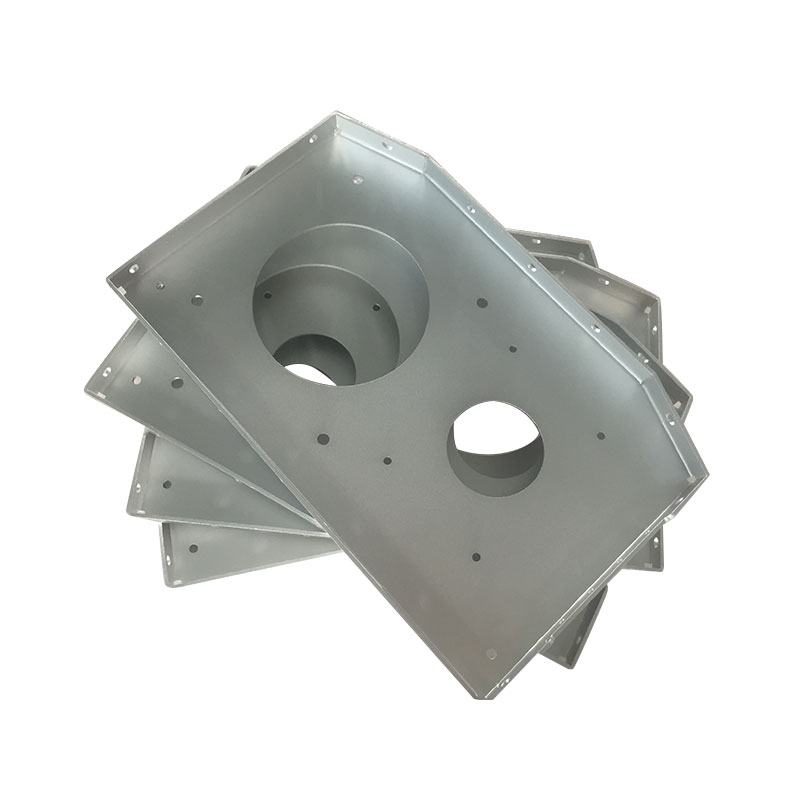

Galvanized Steel Sheet Metal Bending Parts

Galvanized steel sheet metal bending parts or galvanealed steel, which is galvanized then annealed.

Galvanization is the process of applying a protective zinc coating to steel in order to prevent rust and corrosion. Annealing is a heat treatment process that alters the microstructure of a material to change its mechanical or electrical properties, typically reducing the hardness and increasing the ductility for easier fabrication.Aluminium Anodizing Military Parts CNC Turning

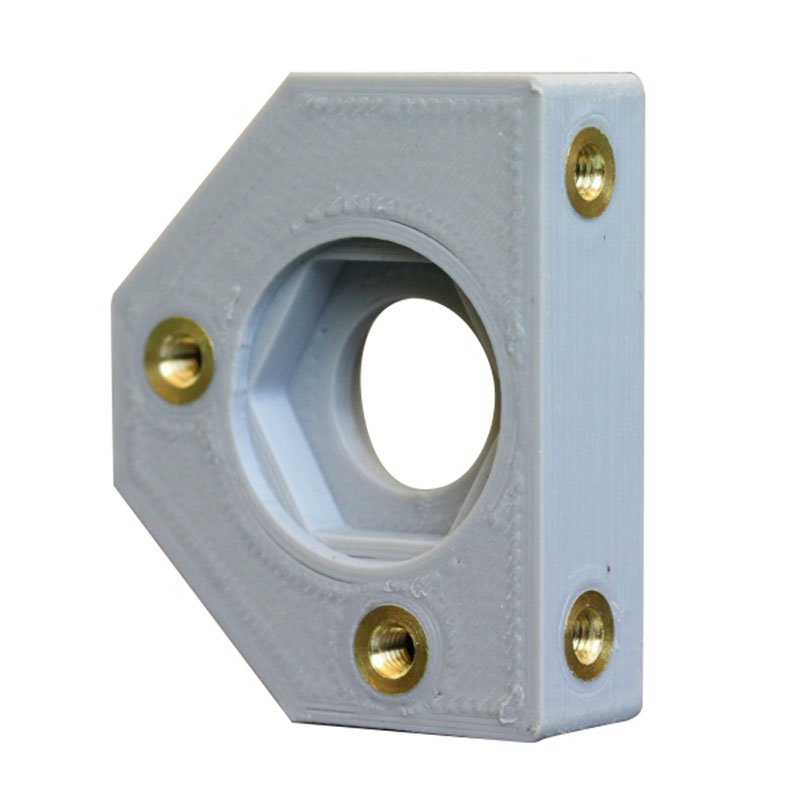

The Aluminium Anodizing Military Parts CNC Turning provided by Shbury are made of 6061 aluminum using CNC milling, turning and drilling machines for a variety of equipment. Our precision machining services have the ability to upgrade your current design to solid piece with the exact specification, also ensure consistent quality and short lead time for your custom prototype and low/high volume production parts. Black anodizing process is applied on the Aluminium Anodizing Military Parts CNC Turning, which increases the thickness of the natural oxide layer on the surface of aluminum components, and improves its corrosion and wear resistance. Our aluminum anodizing services provide an anodized aluminum coating that meets industry standards. Other colors can be dyed during the process. More surface treatment services available to give your aluminum drilling parts or milling parts a smooth surface finish.Computer Housing Products CNC Machining

The following is about Computer Housing Products CNC Machining.Aluminum Sheet Metal Fabrication

Aluminum is a very common metal utilized at Shbury to manufacture various OEM products for wide-ranging applications: on-highway vehicle doors/body panels, medical equipment, medical carts, energy dispensing stations, digital display, and variable messaging controls, consumer products, kiosks, various enclosures, and countless other parts. The following is about aluminum sheet metal fabrication.High Precision Medical Device Parts CNC Machining

High Precision Medical Device Parts CNC Machining Shbury is a trusted supplier of medical device parts. Shbury is committed to improving the quality of life for patients and medical staff throughout the industry. Backed by over 10 years of CNC experience, our skilled machinists are able to create a custom medical component with the greatest accuracy possible3D Printing Electronic Products Rapid Prototypes

Consumers have come to expect periodic releases of ever-more advanced electronics. From smartphones to smart home systems and wearables, new consumer products require significant evaluation and testing before they hit the market. Before moving to mass manufacturing, these new products require rigorous testing for quality, functionality, and user experience.

With new consumer product upgrade and release cycles becoming tighter, electronics designers need a solution that helps reduce the time involved in each R&D and prototyping cycle. By far, the most time-consuming and least productive portion of R&D is repetitive design, build, and test cycles.

Rapid prototyping with traditional manufacturing processes is anything but fast, so designers need a real solution for true rapid prototyping. This illustrates the value of 3D printing in consumer electronics development and prototyping; designers can quickly create fully-functional electronics in a matter of hours rather than days, and this can be done in-house. Designers can innovate more often, quickly test functionality, and implement redesigns before manufacturing at scale. The following is about 3D Printing Electronic Products Rapid Prototypes.