China Auto Components Heat Treatment Rapid Prototypes Manufacturers, Suppliers, Factory

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Auto Components Heat Treatment Rapid Prototypes,Auto Products Heat Treatment Rapid Prototypes, Top quality, timely company and Aggressive cost, all win us a superior fame in xxx field despite the international intense competition.

Auto Components Heat Treatment Rapid Prototypes, We've exported our solutions all over the world, especially the USA and European countries. Furthermore, all of our merchandise are manufactured with advanced equipment and strict QC procedures to ensure high quality.If you are interested in any of our products and solutions, please don't hesitate to contact us. We are going to try our best to meet your needs.

Hot Products

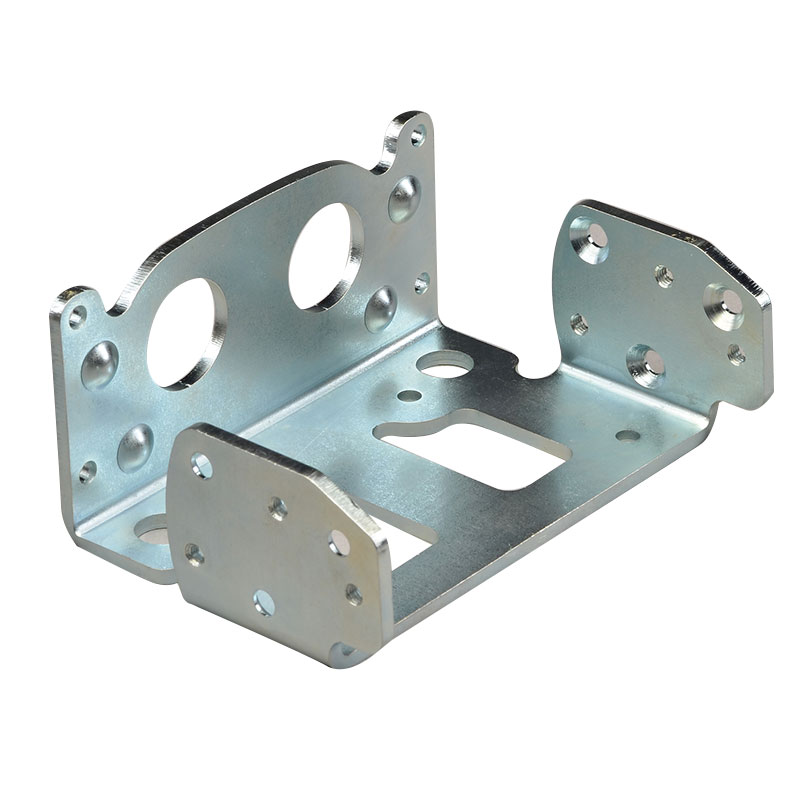

Auto Hydraulic Valve Parts CNC Machining

For more than 10years,Shbury Tech has specialized in machining and manufacturing a wide range of hydraulic parts and components. Our state-of-the-art CNC machining capabilities allow us to provide hydraulic machining services for many industries.

Our qualified engineering team and skilled CNC machinists use advanced machining equipment to produce complex fluid control hydraulic parts at high levels of quality and precision.

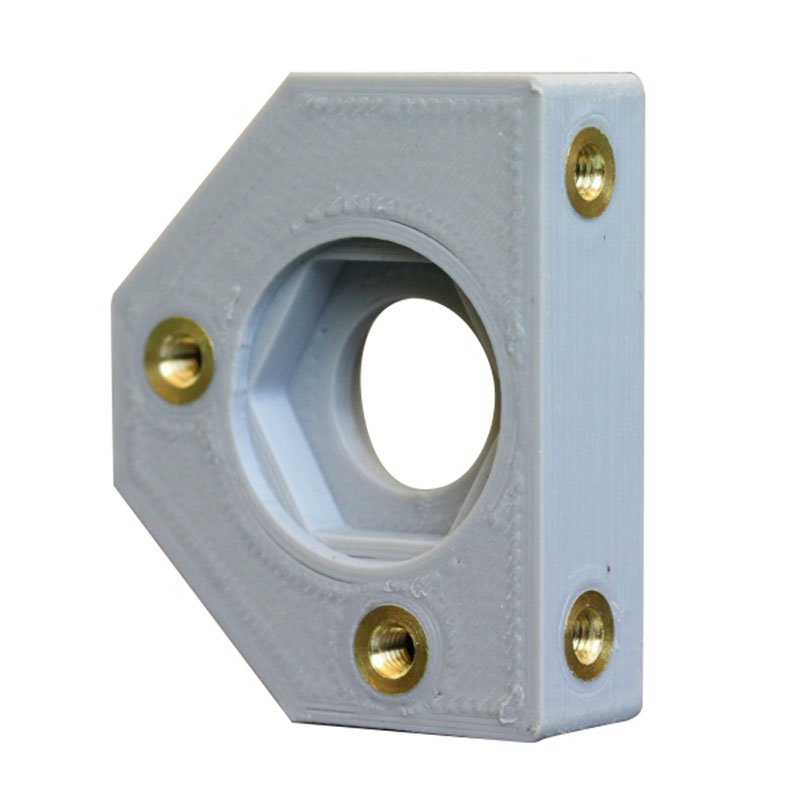

We manufacture a variety of individual hydraulic components and parts such as cylinder & rods, components for motors, pumps, fittings and hose hardware. Our range of secondary services, including anodizing, heat treating, passivating, plating, and assembly, gives us the ability to provide single-source solutions that simplify our customer’s supply chain, thus reducing manufacturing costs and improving turnaround times and overall customer satisfaction. The following is about auto hydraulic valve parts CNC machining.Auto Transmission Parts CNC Turning

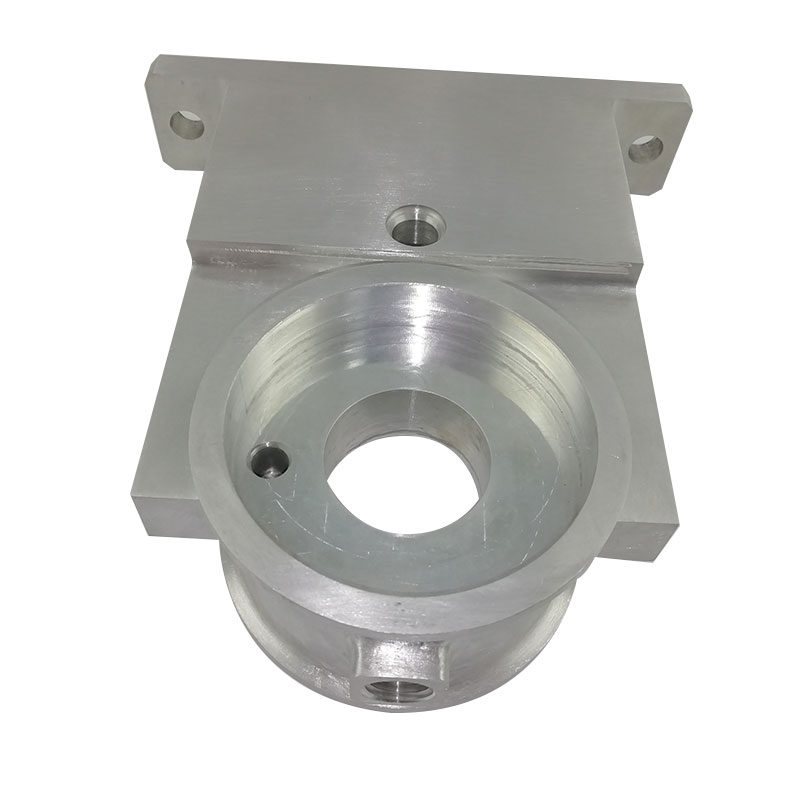

The following is about Auto Transmission Parts CNC Turning.Car Engine Housing Parts CNC Machining

For some automotive components, CNC machining, which involves carrying out tasks like drilling and boring with computer control and automation, now serves as a favourable option for both prototyping and production.

CNC machines turn a digital file into a sequence computer instruction, which are sent to a motorised tool such as a drill, lathe or mill. The tool turns a block of material into a finished product by cutting it in the appropriate places, providing much greater accuracy than conventional machining.The following is about car engine housing parts CNC machining.Sheet Metal Stamping Precision Stamping Parts

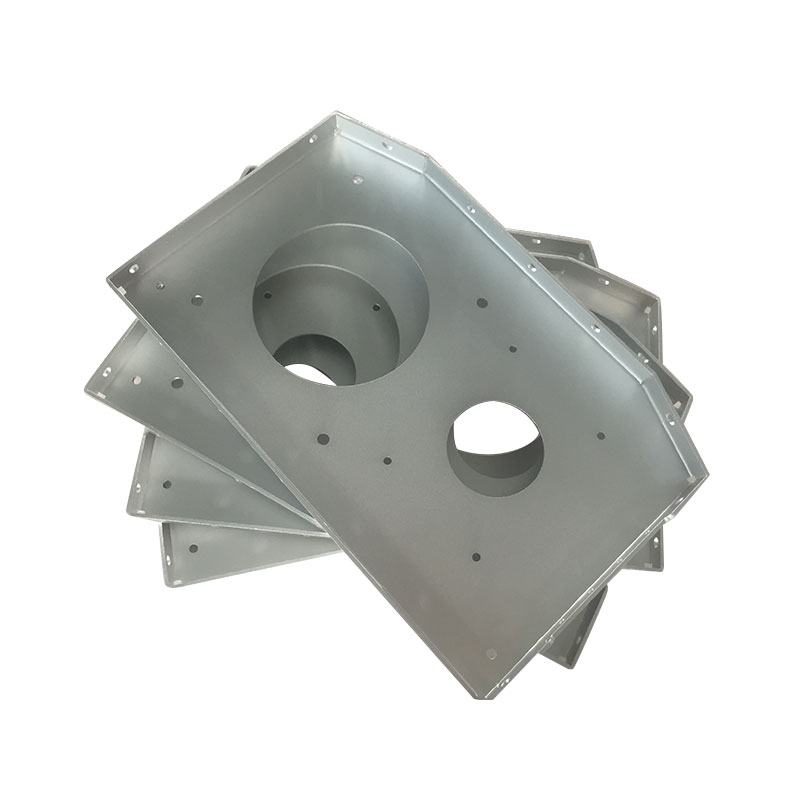

Hot sale quality Sheet Metal Stamping Precision Stamping Parts with Low Price made in China. Guoye Optoelectronics is Sheet Metal Stamping Precision Stamping Parts manufacturer and supplier in China.Polishing Cast Bronze Brass Copper Casting

China Polishing Cast Bronze Brass Copper Casting Factory Directly Supply. Guoye Optoelectronics is Polishing Cast Bronze Brass Copper Casting manufacturer and supplier in China.Stainless Steel Passivating Mechanical Rapid Prototypes

Stainless steel refers to steel that is resistant to weak corrosive media such as air, steam, water, and chemically etched media such as acid, alkali, salt, etc., also known as stainless acid-resistant steel. In practical applications, steel that is resistant to weak corrosive media is often referred to as stainless steel, while steel that is resistant to chemical media is referred to as acid-resistant steel. Due to the difference in chemical composition between the two, the former is not necessarily resistant to chemical media corrosion, while the latter generally has rust.The following is about Stainless Steel Passivating Mechanical Rapid Prototypes.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy