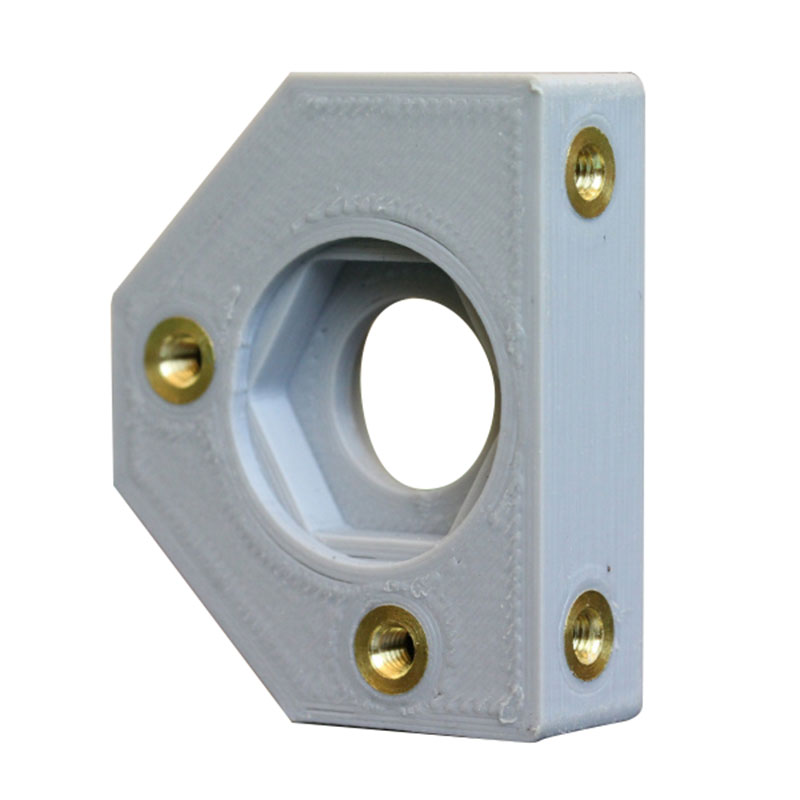

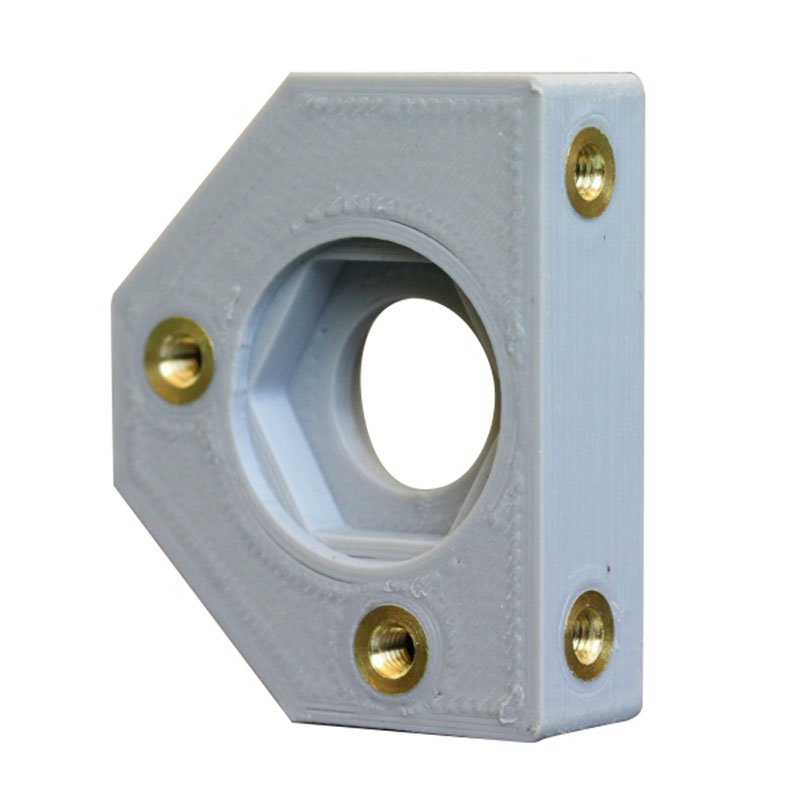

Silicone Buttons Products Vacuum Casting

Send Inquiry

Silicone Buttons Products Vacuum Casting

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production

1.Product ParameterforSilicone Buttons Products Vacuum Casting

|

Standard lead time |

Up to 10 copies within 15 working days |

|

Standard accuracy |

±0.3% (with lower limit on ±0.3 mm on dimensions smaller than 100 mm) |

|

Minimum wall thickness |

To ensure that the mold is filled properly, a wall thickness of at least 0.75 mm is necessary. For best results, we recommend a wall thickness of at least 1.5 mm |

|

Maximum part dimensions |

The size of the mold is limited by the dimensions of the vacuum chamber (1900 x 900 x 750 mm) and by the volume of the product (maximum volume: 10 liters) |

|

Typical quantities |

Up to 25 copies per mold (depending on the mold’s complexity and the casting materials) |

|

Surface structure |

High-quality surface finish comparable to injection molding |

2.Product Feature for Silicone Buttons Products Vacuum Casting

Technical Specifications

1 Standard lead time: Up to 10 copies

within 15 working days

2 Standard accuracy : ±0.3% (with a lower limit on ± 0.3 mm on dimensions

smaller than 100 mm)

3 Minimum wall thickness: To ensure that the mold is filled properly, a wall

thickness of at least 0.75 mm is necessary. For best results, we recommend a

wall thickness of at least 1.5 mm

4 Maximum part dimensions: The size of the mold is limited by the dimensions of

the vacuum chamber (1900 x 900 x 750 mm) and by the volume of the product

(maximum volume: 10 liters)

5 Typical quantities: Up to 25 copies per mold (depending on the mold’s

complexity and the casting materials)

6 Surface structure: High-quality surface finish comparable to injection

molding

3.Product Details for Silicone Buttons Products Vacuum Casting

1. Vacuum Casting Is Fast

First, it’s important to note that all vacuum casting operations begin with a master pattern. This pattern is a solid replica of the intended final part, often made with 3D printing or CNC machining.

Once the master pattern is ready, a mold can be made from it in less than two days – one day to pour the silicone, another day for full curing. This is much faster than it would take to make a plastic injection mold from steel or aluminum. And, once a mold is ready, resin can be poured into the cavity to make a finished product in another two days. Taken together, the development process from concept to finished product – including making the master pattern – can be done in less than one week, sometimes even much faster than that.

2. Vacuum Cast Parts Are High Quality

Resin cast copies of master patterns demonstrate excellent fidelity to the original pattern. This includes not only dimensions and tolerances but also fine surface detail and texture. That means that resin cast prototypes can look and perform almost exactly like production quality plastic injection molded parts. They can also be post-machined just as with any other solid part.

This excellent surface texture also makes it easy to apply a final paint finish without needing extra sanding or polishing preparation.

3. Multiple Materials and Overmolding

Medical products often come in the form of cases or enclosures that use panels, screens, buttons, keypads, and other interactive elements. This is more common as medical equipment become increasingly digital and interconnected.

And these control surfaces and keypads often use soft elastomers or other rubber-like materials as overmoldings. It’s possible to mold two or more dissimilar materials into a single finished piece using vacuum casting. Of course this can be done with injection molding but it’s a much more expensive and time-consuming operation that requires separate hard tools.

4. Many Types of Plastic Are Available

Products used in a healthcare environment must exhibit many different kinds of chemical and mechanical properties. They may need to be strong, rigid, heat and chemical resistant, biocompatible, transparent, easily cleaned and sterilized, etc. To meet these needs, there are pourable casting resins available that can match all of these qualities and more. This is especially beneficial when preparing a new prototype idea for medical certification such as is required by the FDA.

5. Vacuum Casting Is Affordable

It is always important to control costs at every stage of production and this also applies to prototyping. Making a master pattern for vacuum casting, as well as making the silicone molds and the resin copies, is a small investment. In most cases it requires a much smaller initial investment than alternate methods such as 3D printing or CNC machining. This savings can then be applied to further product development and eventual full production.

6. Molded-in Color

Another unique advantage of vacuum casting is that resins can be colored with dyes and pigments just before they are poured into the mold. This yields a finished product in any color so it doesn’t require further painting. This is unlike injection molding, where the product developer needs to commit to a minimum volume of raw material that can be colored with master batch pigment.

4.FAQ

|

Q1:Where can I get product&price information? |

|

A1:Send us inquirye-mail, we will contact you as we receive your mail. |

|

Q2:How long can i get the sample? |

|

A2:Depends on your specific items,within 3-7 days is required generally. |

|

Q3:What's kinds of information you need for quote? |

|

A3:Kindly please provide the product drawing in PDF,and will be better you can provde in STEP or IGS, send the parts materials, quantity, surface finishing and other requirements to us as well. |

|

Q4: what's the payment terms? |

|

A4: We accept 50% as payment deposit, when the goods is done, we take photoes for your check and you then pay the balance. |

|

For small amount, we also accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred |

|

Q5.Are you a trading company or factory? |

|

A5:We are direct factory with 10 experienced engineers and more than 30 employees as well approximate 3,000 square meters workshop area. |

|

Q6. What shall we do if we do not have drawings? |

|

Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order. |

|

Q7. Can we get some samples before mass production? |

|

A7.Absolutely |

|

Q8. What is your MOQ? |

|

Our MOQ is 1pcs, it is also our one of advantage, even you have less budget, or want to reduce the risks before production, we both can accept the less MOQ. |

|

Q9: Will you do 100% inspection or random inspection ? |

|

We will do 100% inspection for samples, random inspection for mass production. When manufacturing, we will control the dimensions , do PQC in mass production. |

|

Q10. How to do if the parts not match with drawings we received? |

|

Contact us immediately, send the pictures and tell us the issues, we will check and repair or re-make the goods with free. |

|

Q11. You will how to ship the parts to me? |

|

When products finished, also passed by our QC, we will ship out the parts to you by DHL, Fedex , or by sea after communication |

5.Deliver,Shipping for Mobile Phone Housing Products Vacuum Casting