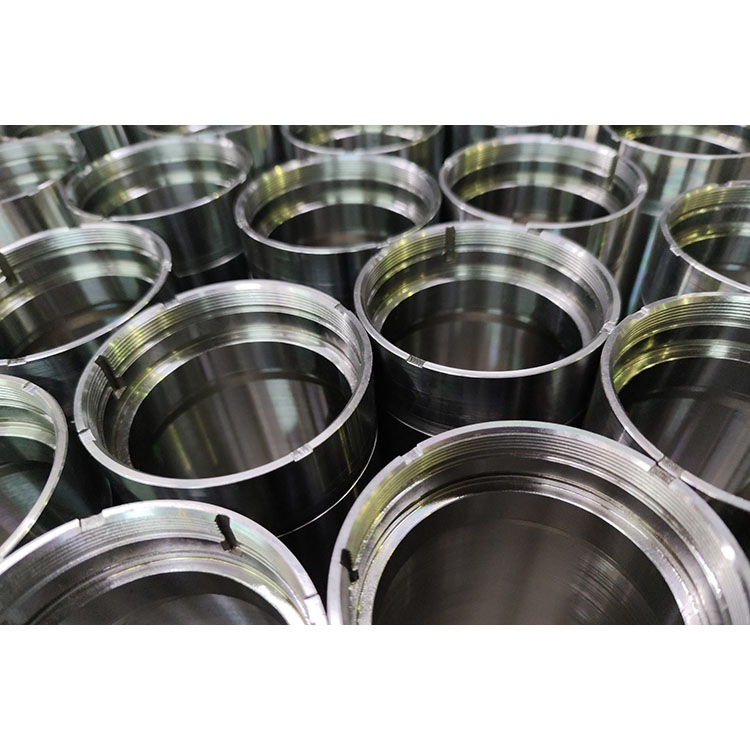

China Auto Oil And Gas Rubber Products Vacuum Casting Manufacturers, Suppliers, Factory

Our intention would be to provide top quality products and solutions at competitive charges, and top-notch support to customers around the world. We have been ISO9001, CE, and GS certified and strictly adhere to their quality specifications for Auto Oil And Gas Rubber Products Vacuum Casting,Auto Oil And Gas Rubber Components Vacuum Casting, Our organization has been devoting that "customer first" and committed to helping clients expand their small business, so that they become the Big Boss !

Auto Oil And Gas Rubber Products Vacuum Casting, During the short years, we serve our clients honestly as Quality First, Integrity Prime, Delivery Timely, which has earned us an outstanding reputation and an impressive client care portfolio. Looking forward to working with you Now!

Hot Products

Electronic Probes Products Cnc Turning

CNC Probe is the contact medium of electrical testing, which is a high-end precision electronic hardware component. Probing is Standard routines built into modern CNC controls simplify the integration of probing cycles into CNC machining operations and offline tools. These routines, combined with a CAD interface, make the simulation of measurement functions easy.

Probe is a very useful addition to any CNC machine, which are used for fast and automatic workpiece measurement and workpiece zero point measurement in CNC machine tools. Specially designed for the harsh conditions in these machines, the probe systems are an established best practice for maximising the efficiency, quality, capability and accuracy of machine tools.The following is about Electronic Probes Products Cnc Turning.Electronic Nozzle Products Cnc Turning

CNC aluminum tubes/pipe also known as the CNC machine nozzle, have the characteristics of corrosion resistance and lightweight, and are widely used in various industries, such as automobiles, aerospace, aviation, electronics industry, agriculture, electromechanical and so on. Aluminum pipes/tubes are ubiquitous in our life. But it’s most commonly used for shisha/hookah, tattoo or e-cigarette.The following is about Electronic Nozzle Products CNC Turning.Airframe Plastic Parts Vacuum Casting

Advantages of Vacuum Casting Technology Possibility of casting parts of complicated shapes, thin-wall parts or parts with negative bevels. Production of small series of prototype or final parts (from dozens up to hundreds of pieces). Favourable production costs in comparison with plastic injection moulding – the production of metal moulds is unnecessary. Fast production – a matter of days. The accuracy of production is comparable with the accuracy of parts manufactured by plastic injection moulding. A wide range of possibilities for final surface treatment.The following is about Airframe Plastic Parts Vacuum Casting.Cold Rolled Steel Sheet Metal Parts

Cold Rolled Steel Sheet Metal Parts have been available for many, many years, and have been successfully used for a multitude of applications. Today's Cold Rolled Steel Sheet Metal Parts are much improved over those used in the past. They offer better control of thickness, shape, width, surface finish, and other special quality features that compliment the emerging need for highly engineered end use applications.Mobile Phone Housing Products Vacuum Casting

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about mobile phone housing products vacuum casting.Smart Mechanical Parts Vacuum Casting

Vacuum casting services is a type of rapid prototyping technology. It is used for producing a photocopy of the original product in a vacuum state, and then use (PU, transparent PU, POM-like, ABS) and other materials to cast the same copy as the product prototype.

Vacuum casting services are suitable for the customer who requires several sets of rapid prototype parts, which significantly reduces the cost and development time. The following is about Smart Mechanical Parts Vacuum Casting.