China Medical Device Liquid Silicone Vacuum Casting Products Manufacturers, Suppliers, Factory

Our corporation puts emphasis about the administration, the introduction of talented staff, plus the construction of team building, attempting hard to improve the quality and liability consciousness of team members. Our organization successfully attained IS9001 Certification and European CE Certification of Medical Device Liquid Silicone Vacuum Casting Products,Medical Device Liquid Silicone Vacuum Casting Components, We have been sincerely wanting forward to cooperate with consumers all over the earth. We feel we can easily satisfy with you. We also warmly welcome buyers to visit our manufacturing unit and purchase our products and solutions.

Medical Device Liquid Silicone Vacuum Casting Products, In order to meet our market demands, we now have paied more attention to the quality of our products and solutions and services. Now we can meet customers' special requirements for special designs. We persistently develop our enterprise spirit "quality lives the enterprise, credit assures cooperation and keep the motto in our minds: customers first.

Hot Products

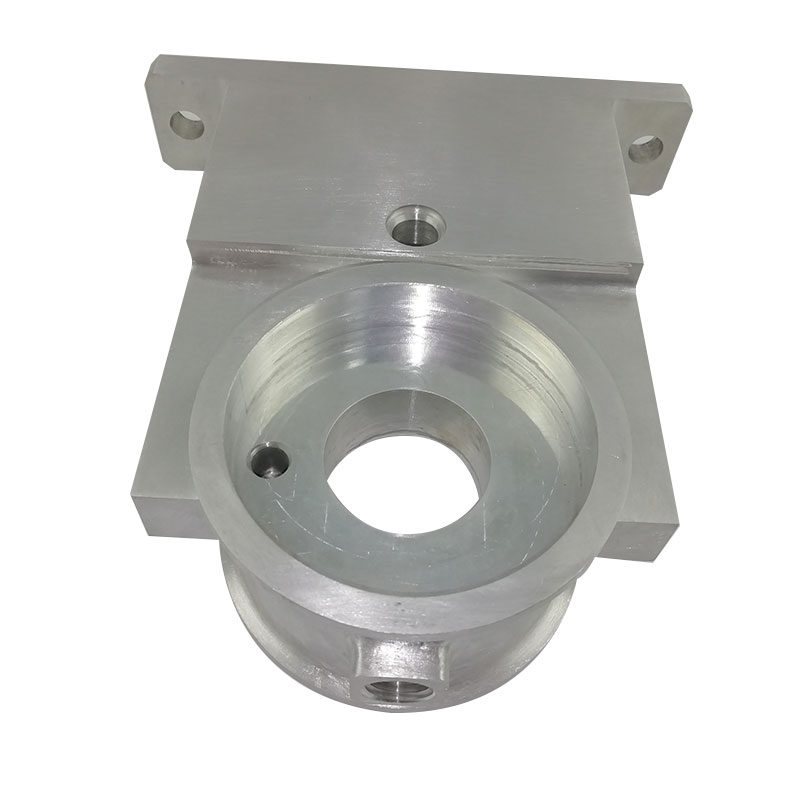

Auto Pipe Joint Parts CNC Machining

One of the top CNC machining service suppliers in Shbury Tech, has been specialized in producing custom CNC turning pipe joints (expansion, welding, clamp) for automobile industry for over 10 years with superior quality and OEM service. Our products of CNC turned and machined pipe joint include zinc, iron, aluminum pipe joint, metal pipe joint, steel, stainless steel, brass pipe joint and other types of CNC lathe machine pipe joint. Reliable auto pipe joints are supplied to consumers with high-precision and stable quality and competitive prices.The following is about auto pipe joint parts CNC machining.Agricultural Machinery Parts CNC Machining

Agricultural Industry is ever evolving, one thing hasn’t changed at all: agricultural equipment component failure can have major implications for a project or a crop. Since agriculture parts are large and complex, all agriculture parts which are used on the agricultural equipment must be carefully worked with high demands of technical specifications including tight tolerance, ultra-high precision specifications, and the best durable materials to ensure the machines and equipment’ service life. So customized CNC machining services for agricultural equipment is very important in the agriculture parts manufacturing field, also custom CNC agricultural parts can make your equipment more competitive in the market.The following is about agricultural machinery parts CNC machining.Stainless Steel Passivating Mechanical Rapid Prototypes

Stainless steel refers to steel that is resistant to weak corrosive media such as air, steam, water, and chemically etched media such as acid, alkali, salt, etc., also known as stainless acid-resistant steel. In practical applications, steel that is resistant to weak corrosive media is often referred to as stainless steel, while steel that is resistant to chemical media is referred to as acid-resistant steel. Due to the difference in chemical composition between the two, the former is not necessarily resistant to chemical media corrosion, while the latter generally has rust.The following is about Stainless Steel Passivating Mechanical Rapid Prototypes.High Precision Medical Device Parts CNC Machining

High Precision Medical Device Parts CNC Machining Shbury is a trusted supplier of medical device parts. Shbury is committed to improving the quality of life for patients and medical staff throughout the industry. Backed by over 10 years of CNC experience, our skilled machinists are able to create a custom medical component with the greatest accuracy possibleEco-friendly Low Price CNC Machining Aluminum anodizing Plate Parts

Eco-friendly Low Price CNC Machining Aluminum anodizing Plate Parts:If you need aluminum parts cnc machined we are one of the most capable and affordable sources specializing in manufacturing precision machined parts on advanced cnc machines. With rich knowledge and experience, our cnc machine shop is able to produce parts that require innovative tooling and fixturing in a timely manner with competitive price. We do cnc machining on 4,5 axis all kinds of aluminum with 6061 and 7075 being the most used.Plastic Electronic Products CNC Machining

The role of Plastic Electronic Products in the electronics industry has increased exponentially. The continual growth of electronic and engineering devices has led to the designing and manufacturing of various standard and custom plastic products, which can support industrial electronic applications.The following is about Plastic Electronic Products CNC Machining.