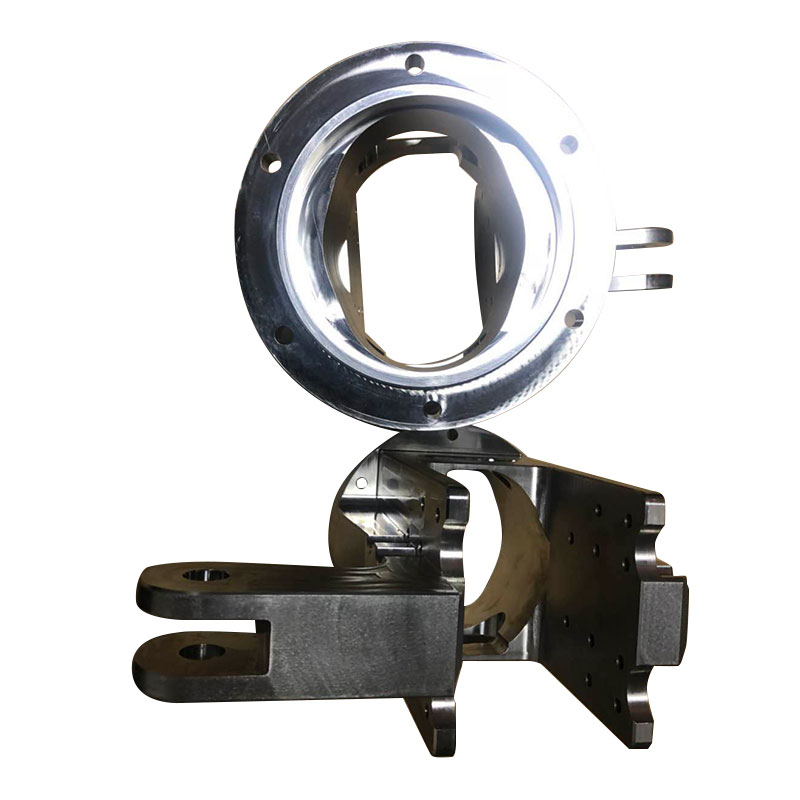

Aerospace Seal Parts Vacuum Casting

Send Inquiry

Aerospace Seal Parts Vacuum Casting

Silicone is cheaper in terms of cost compared to the injection mold. The reason for this difference in cost, is the nature of injection mold, being built on steel or aluminum parts. The cost if silicone mold can be from hundreds to thousands while the injection one will range from thousands to tens of thousands. With reliable quality process, good reputation and perfect customer service, the series of products produced by our company are exported to many countries and regions for Newly Arrival China New Technology Aerospace Seal Parts Vacuum Casting, We are generally looking ahead to forming effective business associations with new clientele around the world. Newly Arrival China Vacuum, Casting, If any product meed your demand, please feel free to contact us. We're sure your any inquiry or requirement will get prompt attention, high-quality products and solutions, preferential prices and cheap freight. Sincerely welcome friends all over the world to call or come to visit, to discuss cooperation for a better future!

1.Product Parameter for Aerospace Seal Parts Vacuum Casting

|

Standard lead time |

Up to 10 copies within 15 working days |

|

Standard accuracy |

±0.3% (with lower limit on ±0.3 mm on dimensions smaller than 100 mm) |

|

Minimum wall thickness |

To ensure that the mold is filled properly, a wall thickness of at least 0.75 mm is necessary. For best results, we recommend a wall thickness of at least 1.5 mm |

|

Maximum part dimensions |

The size of the mold is limited by the dimensions of the vacuum chamber (1900 x 900 x 750 mm) and by the volume of the product (maximum volume: 10 liters) |

|

Typical quantities |

Up to 25 copies per mold (depending on the mold’s complexity and the casting materials) |

|

Surface structure |

High-quality surface finish comparable to injection molding |

2.Product Feature forAerospace Seal Parts Vacuum Casting

- Can create big parts of up to 48” x 96”

- It takes less time for production to be complete.

- Cost of the mold is relatively cheaper since they are built on MDF, high-density foam, and epoxy

- The casting process is efficient for pattern or design that requires a lot of repetition.

3.Product Details forAerospace Seal Parts Vacuum Casting

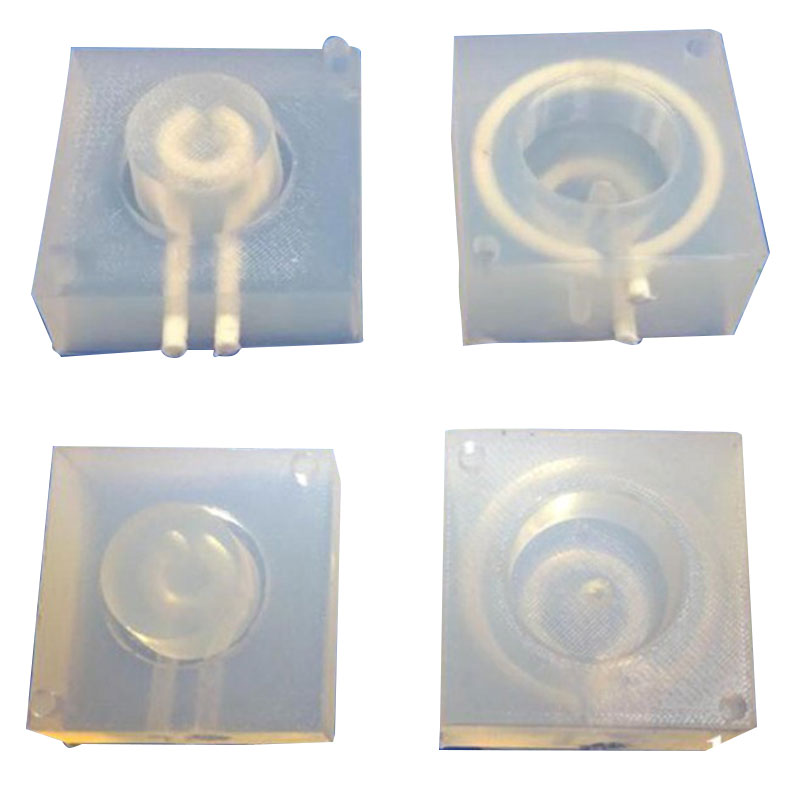

Silicone Mold vs. Injection Mold

1. Financing Cost

Silicone is cheaper in terms of cost compared to the injection mold. The reason for this difference in cost, is the nature of injection mold, being built on steel or aluminum parts. The cost if silicone mold can be from hundreds to thousands while the injection one will range from thousands to tens of thousands.

2. Tooling Lead Time

Vacuum casting has a shorter lead time than the injection molding machine. A conventional injection mold will take 4–8 weeks, to be manufactured. Unlike the silicone mold that would only need a 1-2 week to be fully complete and all the complex parts finished in a short time.

3. Types of Material Usage

The material used on both molds range from opaque to transparent; the durometers are an array, from 30A-90D to UL 94-VO. Below is a list of other material types that are used.

4.FAQ

|

Q1:Where can I get product&price information? |

|

A1:Send us inquirye-mail, we will contact you as we receive your mail. |

|

Q2:How long can i get the sample? |

|

A2:Depends on your specific items,within 3-7 days is required generally. |

|

Q3:What's kinds of information you need for quote? |

|

A3:Kindly please provide the product drawing in PDF,and will be better you can provde in STEP or IGS, send the parts materials, quantity, surface finishing and other requirements to us as well. |

|

Q4: what's the payment terms? |

|

A4: We accept 50% as payment deposit, when the goods is done, we take photoes for your check and you then pay the balance. |

|

For small amount, we also accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred |

|

Q5.Are you a trading company or factory? |

|

A5:We are direct factory with 10 experienced engineers and more than 30 employees as well approximate 3,000 square meters workshop area. |

|

Q6. What shall we do if we do not have drawings? |

|

Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order. |

|

Q7. Can we get some samples before mass production? |

|

A7:Absolutely |

|

Q8. What is your MOQ? |

|

Our MOQ is 1pcs, it is also our one of advantage, even you have less budget, or want to reduce the risks before production, we both can accept the less MOQ. |

|

Q9: Will you do 100% inspection or random inspection ? |

|

We will do 100% inspection for samples, random inspection for mass production. When manufacturing, we will control the dimensions , do PQC in mass production. |

|

Q10. How to do if the parts not match with drawings we received? |

|

Contact us immediately, send the pictures and tell us the issues, we will check and repair or re-make the goods with free. |

|

Q11. You will how to ship the parts to me? |

|

When products finished, also passed by our QC, we will ship out the parts to you by DHL, Fedex , or by sea after communication |

5.Deliver,Shipping forAerospace Seal Parts Vacuum Casting