China Metal Aerospace Parts CNC Milling Manufacturers, Suppliers, Factory

Our enterprise insists all along the quality policy of "product high-quality is base of organization survival; customer gratification will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff" and also the consistent purpose of "reputation very first, purchaser first" for Metal Aerospace Parts CNC Milling,Metal Aerospace Products CNC Machining,Metal Aerospace Components CNC Machining,CNC Machining Parts CNC Lathe for Aerospace,CNC Machining Parts in Aerospace Field, In addition, we would properly tutorial the purchasers about the application techniques to adopt our items plus the way to select appropriate materials.

Metal Aerospace Parts CNC Milling, During in 11 years, We have now participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

Hot Products

Servo Motor Shaft Aerospace Parts CNC Turning

Servo Motor Shaft is one of the important parts of the motor. It acts as a link between the electromechanical energy conversion between the motor and the device, supporting the rotating parts, transmitting torque and determining the relative position of the rotating parts to the stator.The following is about Servo Motor Shaft Aerospace Parts CNC Turning.Metal Precision Mechanical Parts CNC Machining

Firstly, parts for robotic applications often have a requirement to be strong, tough and lightweight. Materials such as aluminium have ideal characteristics and can easily be machined using CNC Machining.

Similarly POM (also known as Delrin and Acetal) is commonly used for robotic mechanical cnc machining parts. Easy to machine, it is known for its low friction, high stiffness and superior dimensional stability. As a low-cost plastic, it is also a very economical option.The following is about metal precision mechanical parts CNC machining.Plastic Electronic Products Rapid Prototypes

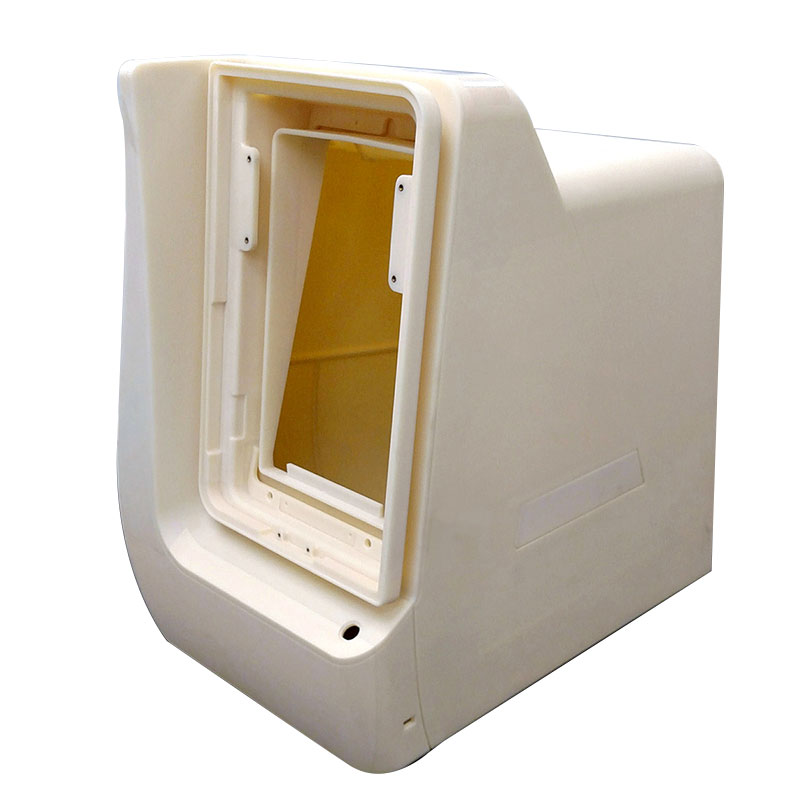

Do you require quick, economic plastic prototypes with production-like material properties? Vacuum casting in silicone molds is the method that you need. Due to the low die costs, vacuum casting is particularly attractive as an economical secondary procedure for the reproduction of models in small batches.The following is about Plastic Electronic Products Rapid Prototypes.Aluminum Sheet Metal Fabrication

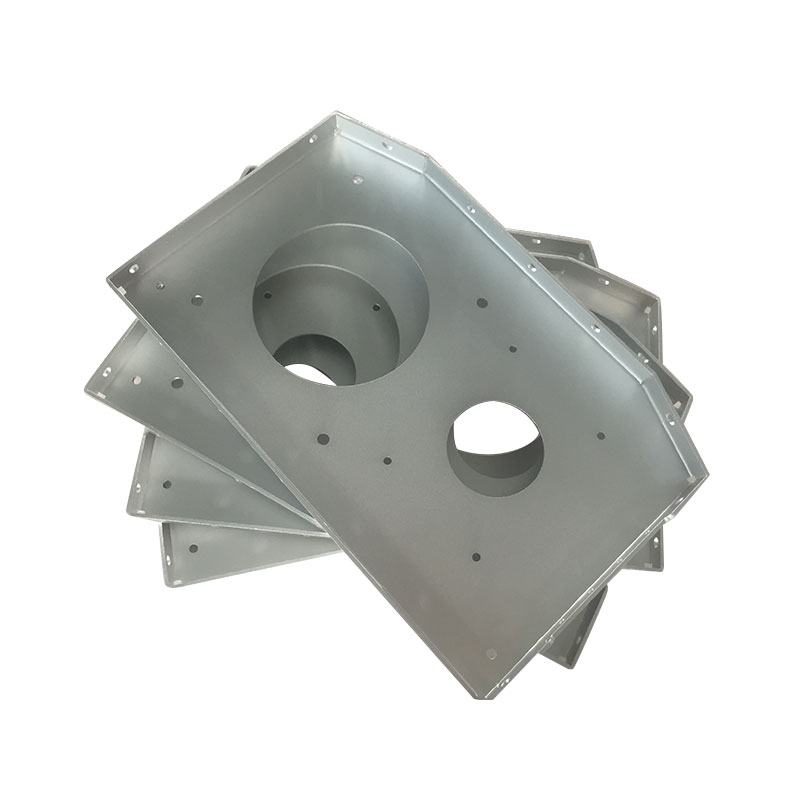

Aluminum is a very common metal utilized at Shbury to manufacture various OEM products for wide-ranging applications: on-highway vehicle doors/body panels, medical equipment, medical carts, energy dispensing stations, digital display, and variable messaging controls, consumer products, kiosks, various enclosures, and countless other parts. The following is about aluminum sheet metal fabrication.Flexible Silicone Electronic Products Vacuum Casting

Urethane Casting - Silicone Molding Vacuum casting (also known as urethane casting or silicone moulding) is a manufacturing method that uses silicone moulds to produce plastic parts in a relatively simple way and without the high costs and high lead times required for steel or aluminium moulds.The following is about flexible silicone electronic products vacuum casting.Airframe Plastic Parts Vacuum Casting

Advantages of Vacuum Casting Technology Possibility of casting parts of complicated shapes, thin-wall parts or parts with negative bevels. Production of small series of prototype or final parts (from dozens up to hundreds of pieces). Favourable production costs in comparison with plastic injection moulding – the production of metal moulds is unnecessary. Fast production – a matter of days. The accuracy of production is comparable with the accuracy of parts manufactured by plastic injection moulding. A wide range of possibilities for final surface treatment.The following is about Airframe Plastic Parts Vacuum Casting.