China Laser Cutting Auto Components Rapid Prototypes Manufacturers, Suppliers, Factory

continue to improve, to ensure product quality in line with market and customer standard requirements. Our company has a quality assurance system have been established for Laser Cutting Auto Components Rapid Prototypes,Laser Cutting Auto Products Rapid Prototypes, We recognize your enquiry and it truly is our honor to work with each and every pal globally.

Laser Cutting Auto Components Rapid Prototypes, Our product quality is one of the major concerns and has been produced to meet the customer's standards. "Customer services and relationship" is another important area which we understand good communication and relationships with our customers is the most significant power to run it as a long term business.

Hot Products

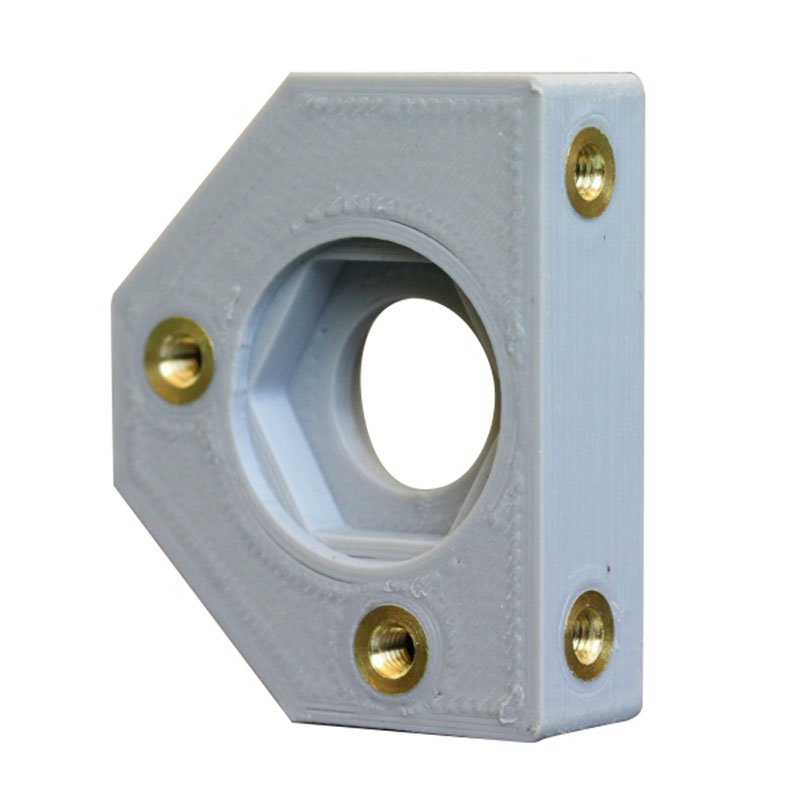

Aluminium Electronic Products Rapid Prototypes

Aluminum alloy is widely used in the industry. It is low in density, high in strength, excellent in elasticity, processability and welding characteristics. It also features good corrosion resistance, high toughness, and deformation after manufacturing.

Aluminum alloy molding can help discover potential flaws early in the product development stage, saving money in the long-run and minimizing production times. Aluminum alloy rapid prototype helps generate accurate product test data.The following is about Aluminium Electronic Products Rapid Prototypes.Carbon Steel Military Parts CNC Turning

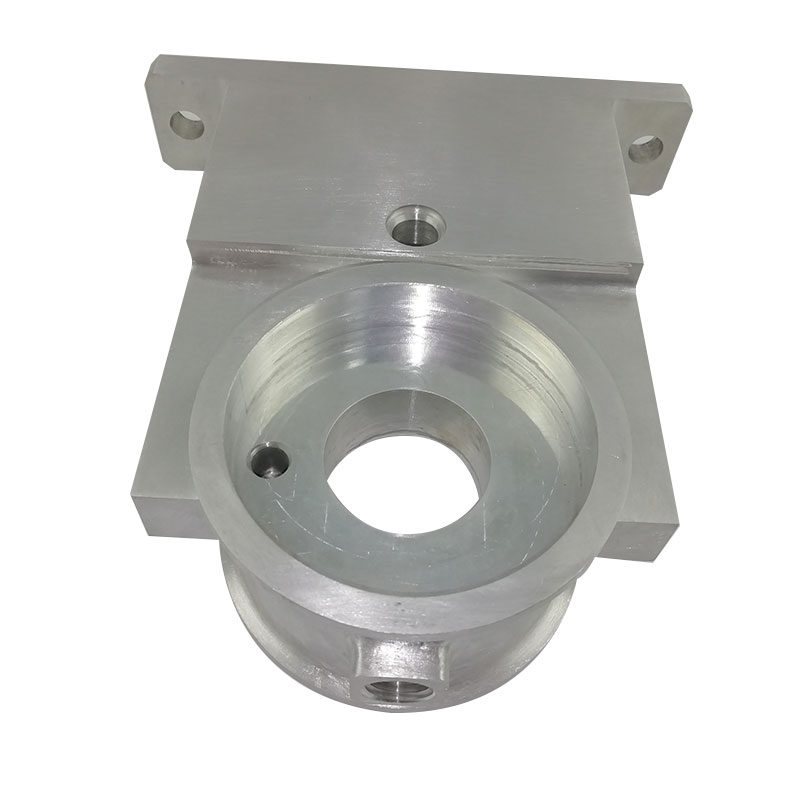

Shbury specializes in precision CNC parts and components that match military standards. We can provide complex machined parts at close tolerances along with accurate supporting documentation. The following is about Carbon Steel Military Parts CNC Turning.Polishing Cast Bronze Brass Copper Casting

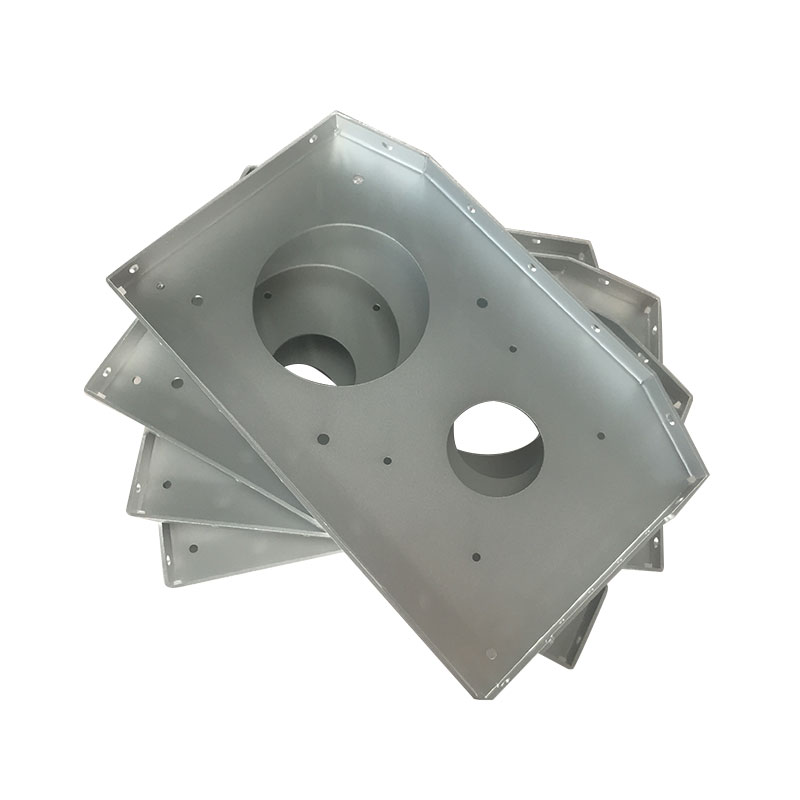

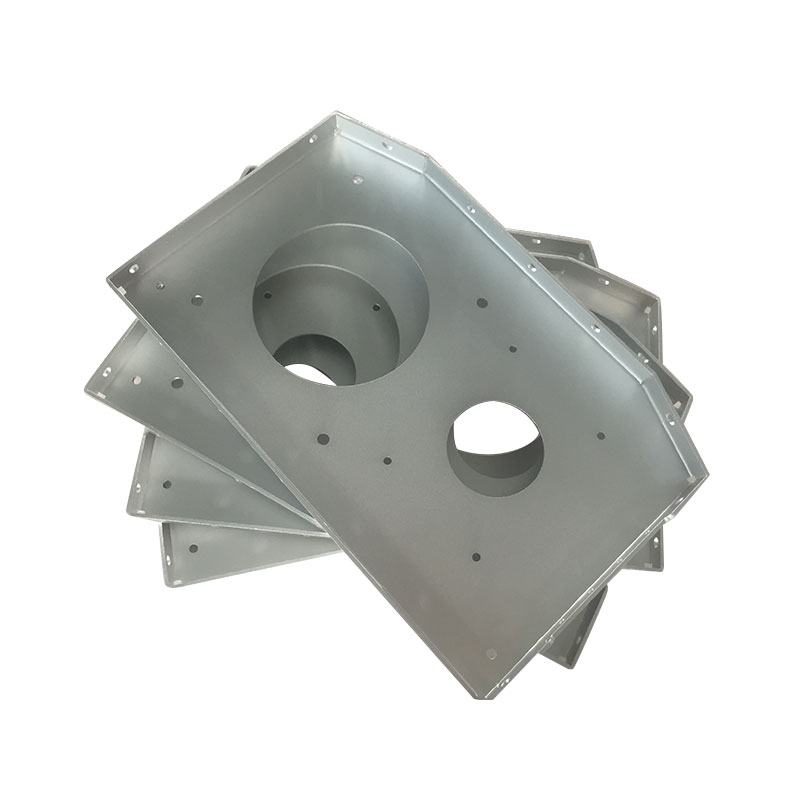

China Polishing Cast Bronze Brass Copper Casting Factory Directly Supply. Guoye Optoelectronics is Polishing Cast Bronze Brass Copper Casting manufacturer and supplier in China.Aluminum Sheet Metal Fabrication

Aluminum is a very common metal utilized at Shbury to manufacture various OEM products for wide-ranging applications: on-highway vehicle doors/body panels, medical equipment, medical carts, energy dispensing stations, digital display, and variable messaging controls, consumer products, kiosks, various enclosures, and countless other parts. The following is about aluminum sheet metal fabrication.Agricultural Machinery Parts CNC Machining

Agricultural Industry is ever evolving, one thing hasn’t changed at all: agricultural equipment component failure can have major implications for a project or a crop. Since agriculture parts are large and complex, all agriculture parts which are used on the agricultural equipment must be carefully worked with high demands of technical specifications including tight tolerance, ultra-high precision specifications, and the best durable materials to ensure the machines and equipment’ service life. So customized CNC machining services for agricultural equipment is very important in the agriculture parts manufacturing field, also custom CNC agricultural parts can make your equipment more competitive in the market.The following is about agricultural machinery parts CNC machining.Precision Machined Sheet Bending Parts

Hot Selling Low Price Precision Machined Sheet Bending Parts. Guoye Optoelectronics is Precision Machined Sheet Bending Parts manufacturer and supplier in China.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy