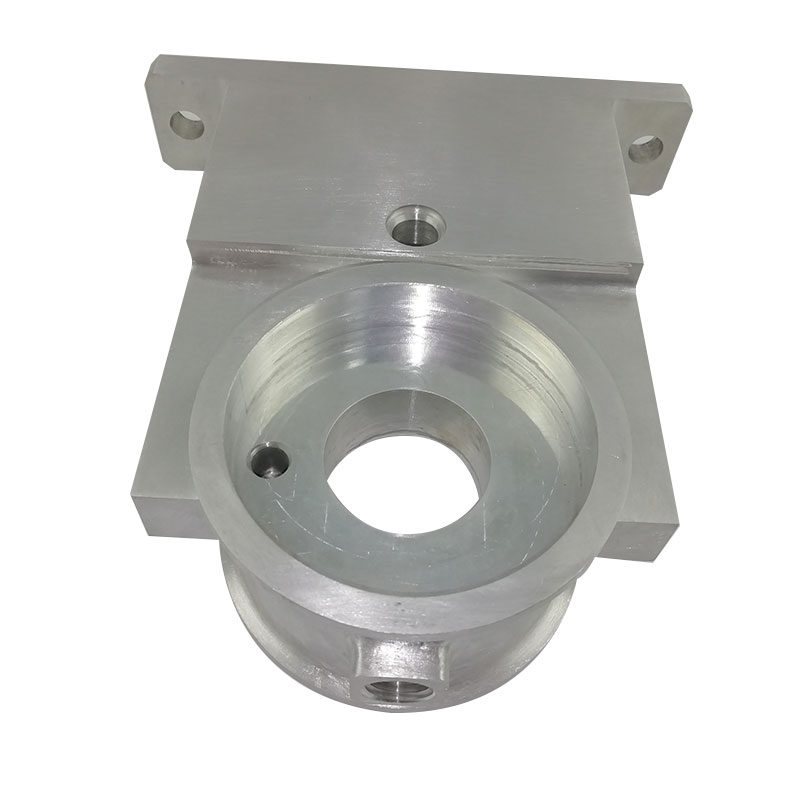

China 4 axis Aluminium Anodizing Parts Manufacturers, Suppliers, Factory

With our superb management, potent technical capability and strict quality command procedure, we go on to provide our shoppers with trustworthy high-quality, reasonable costs and outstanding services. We goal at becoming considered one of your most trustworthy partners and earning your pleasure for 4 axis Aluminium Anodizing Parts,Aluminum 4 axis CNC Machining,CNC Machining, We invites both you and your enterprise to thrive along with us and share a vibrant long term in global sector.

4 axis Aluminium Anodizing Parts, Our next goal is to exceed the expectations of every client by offering outstanding customer service, increased flexibility and greater value. All in all, without our customers we do not exist; without happy and fully satisfied customers, we fail. We're looking for the wholesale, Drop ship. Remember to contact us if you are interesting our goods. Hope to do business with you all. High quality and fast shipment!

Hot Products

Mobile Phone Housing Products Vacuum Casting

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about mobile phone housing products vacuum casting.Vacuum Casting Prototype for Mobile Phone Housing

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about mobile phone housing products vacuum casting.Military Parts Dowel Pins CNC Turning

We carefully consider the dowel pins material to be used as well as the dowel destination. We take into account the ductility of the destination hole and the ductility of the dowel pins material being used to manufacture the machined parts with accurate dimensions. Regarding size and precision, Alpha Omega Swiss manufactures precision dowel pins to exacting tolerances. We can produce dowel pins to a tolerance of +/- .0001 utilizing stainless steel, tool steel, brass, or aluminum.The following is about Military Parts Dowel Pins CNC Turning.Medical X-ray Housing Rapid Prototypes

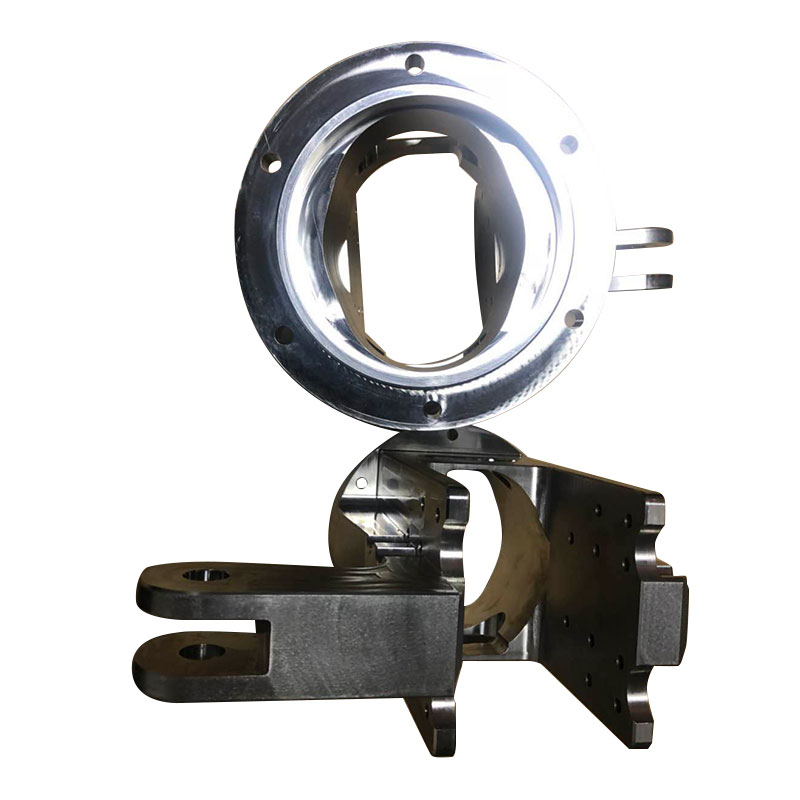

Optometry device cover for medical deviceThe design process for new or improved medical devices, such as catheters, stents, fluid administration systems, drug delivery systems, chemotherapy tips, syringes, cardio-vascular devices, vascular access devices, etc. includes the important step of producing, examining, and testing a physical medical prototype. Engineers and designers benefit from having a medical prototype to sample its size and get an idea of a its form, fit, and feel.The following is about Medical X-ray Housing Rapid Prototypes.Aerospace Couplers Parts CNC Turning

Aerospace Couplers Parts CNC Turning Services With a view to produce superior products for customers, Shbury actively introduced advanced automatic machines. Currently there are several brand-new CNC automatic lathes, automatic secondary processors and other semi-automatic precise machines. Through the smooth operation of the qualified engineers, our products are more stable in quality and efficient of capacity. we are equipped with 10 precision CNC automatic lathes from Japan, as well as a series of precision measuring and QC inspection instruments. we are able to steadily improve technological know-how, lower defective rates, which already helped us to build a solid reputation.Car Engine Housing Parts CNC Machining

For some automotive components, CNC machining, which involves carrying out tasks like drilling and boring with computer control and automation, now serves as a favourable option for both prototyping and production.

CNC machines turn a digital file into a sequence computer instruction, which are sent to a motorised tool such as a drill, lathe or mill. The tool turns a block of material into a finished product by cutting it in the appropriate places, providing much greater accuracy than conventional machining.The following is about car engine housing parts CNC machining.