China Auto Components Powder Coating Rapid Prototype Manufacturers, Suppliers, Factory

We've been experienced manufacturer. Wining the majority on the crucial certifications of its market for Auto Components Powder Coating Rapid Prototype,Auto Products Powder Coating Rapid Prototype, Top quality and competitive rates make our products and solutions appreciate a higher name all around the word.

Auto Components Powder Coating Rapid Prototype, Make sure you feel cost-free to send us your specifications and we'll respond to you asap. We have got a professional engineering team to serve for the every single thorough needs. Free samples may be sent to suit your needs personally to know far more facts. So that you can meet your desires, be sure to genuinely feel cost-free to contact us. You could send us emails and call us straight. Additionally, we welcome visits to our factory from all over the world for much better recognizing of our corporation. nd merchandise. In our trade with merchants of several countries, we often adhere to the principle of equality and mutual advantage. It is our hope to market, by joint efforts, both trade and friendship to our mutual benefit. We look forward to getting your inquiries.

Hot Products

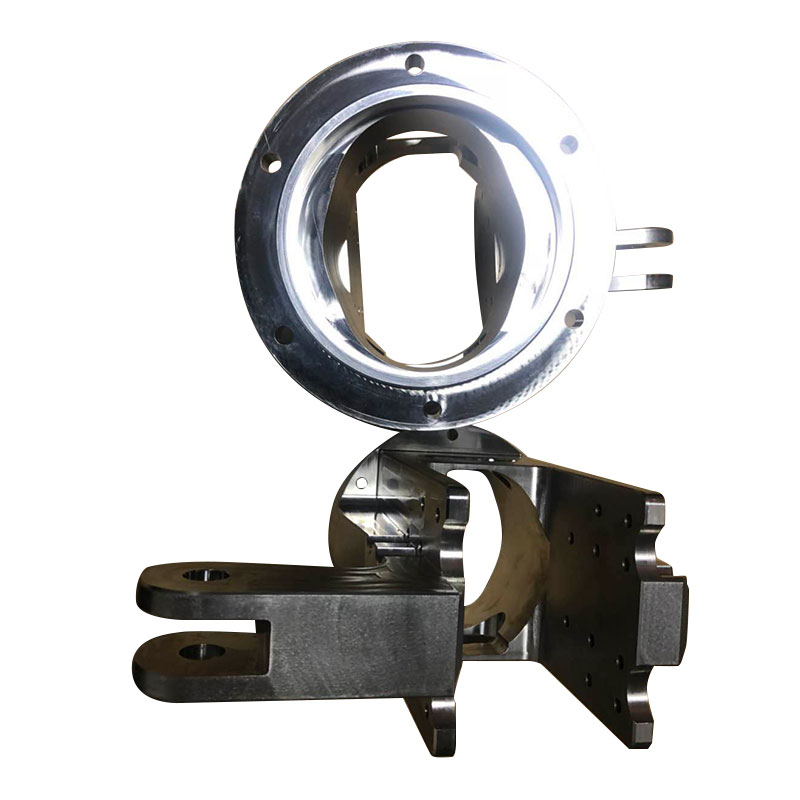

Laser Cutting Auto Parts Rapid Prototypes

Shbury offers rapid prototyping services for laser cut parts. Laser technology allows us to manufacture parts quickly and cost-effectively, allowing us to provide your team with a precision part prototype quickly and cost-effectively. Using the latest CNC technology, we can use your CAD drawings to produce a part without the delays required to design and manufacture tooling.The following is about Laser Cutting Auto Parts Rapid Prototypes.Galvanized Steel Sheet Metal Bending Parts

Galvanized steel sheet metal bending parts or galvanealed steel, which is galvanized then annealed.

Galvanization is the process of applying a protective zinc coating to steel in order to prevent rust and corrosion. Annealing is a heat treatment process that alters the microstructure of a material to change its mechanical or electrical properties, typically reducing the hardness and increasing the ductility for easier fabrication.Auto Hydraulic Valve Parts CNC Machining

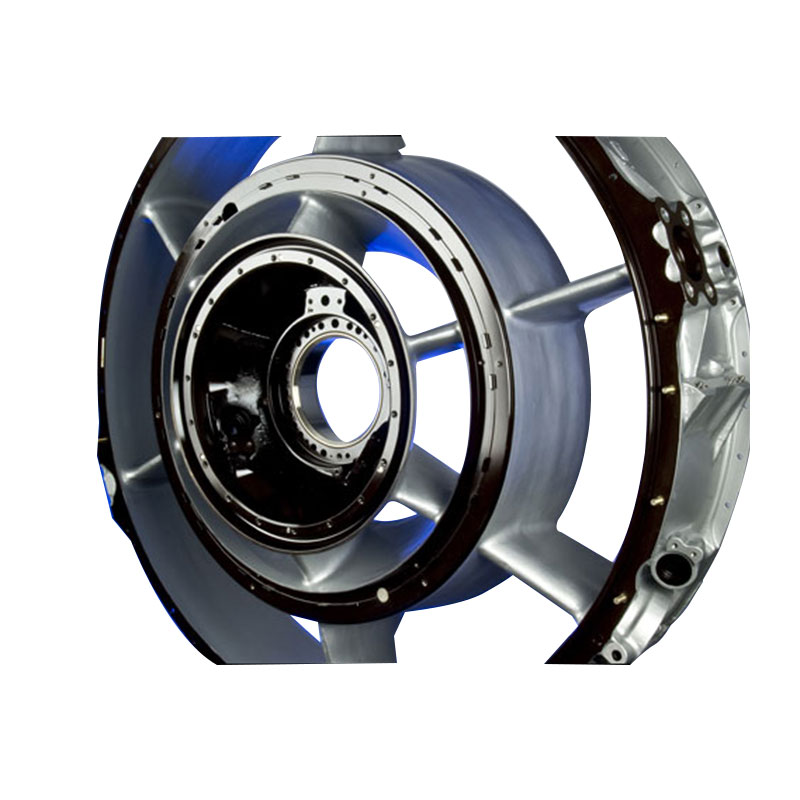

For more than 10years,Shbury Tech has specialized in machining and manufacturing a wide range of hydraulic parts and components. Our state-of-the-art CNC machining capabilities allow us to provide hydraulic machining services for many industries.

Our qualified engineering team and skilled CNC machinists use advanced machining equipment to produce complex fluid control hydraulic parts at high levels of quality and precision.

We manufacture a variety of individual hydraulic components and parts such as cylinder & rods, components for motors, pumps, fittings and hose hardware. Our range of secondary services, including anodizing, heat treating, passivating, plating, and assembly, gives us the ability to provide single-source solutions that simplify our customer’s supply chain, thus reducing manufacturing costs and improving turnaround times and overall customer satisfaction. The following is about auto hydraulic valve parts CNC machining.Brass Inserts Plastic Electronic Products Vacuum Casting

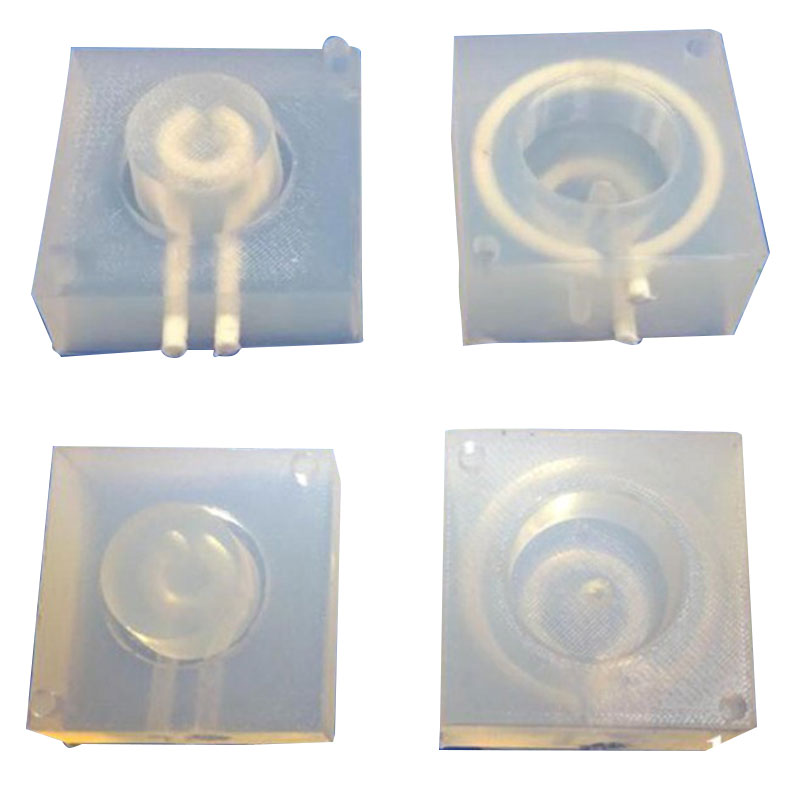

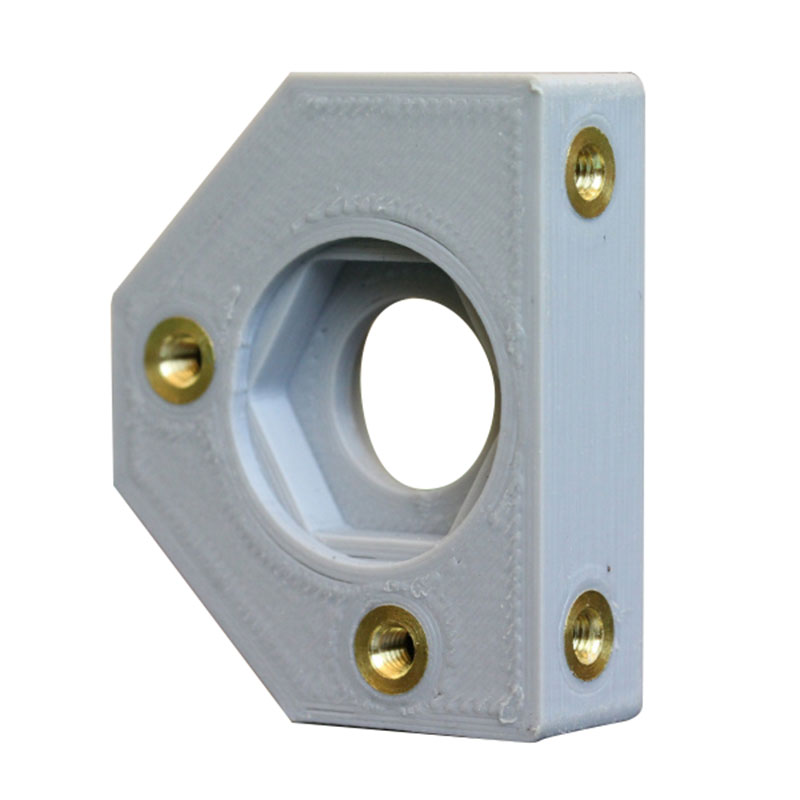

Shbury has a fully equipped Vacuum Casting suite with multiple vacuum casting machines. We also have 3D printing facilities which are used for producing the master pattern. For best quality, we use high definition SLA models.The following is about Brass Inserts Plastic Electronic Products Vacuum Casting.Medical X-ray Housing Rapid Prototypes

Optometry device cover for medical deviceThe design process for new or improved medical devices, such as catheters, stents, fluid administration systems, drug delivery systems, chemotherapy tips, syringes, cardio-vascular devices, vascular access devices, etc. includes the important step of producing, examining, and testing a physical medical prototype. Engineers and designers benefit from having a medical prototype to sample its size and get an idea of a its form, fit, and feel.The following is about Medical X-ray Housing Rapid Prototypes.Medical Device Liquid Silicone Vacuum Casting Parts

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about Medical Device Liquid Silicone Vacuum Casting Parts.