China Car Engine Housing Components CNC Machining Manufacturers, Suppliers, Factory

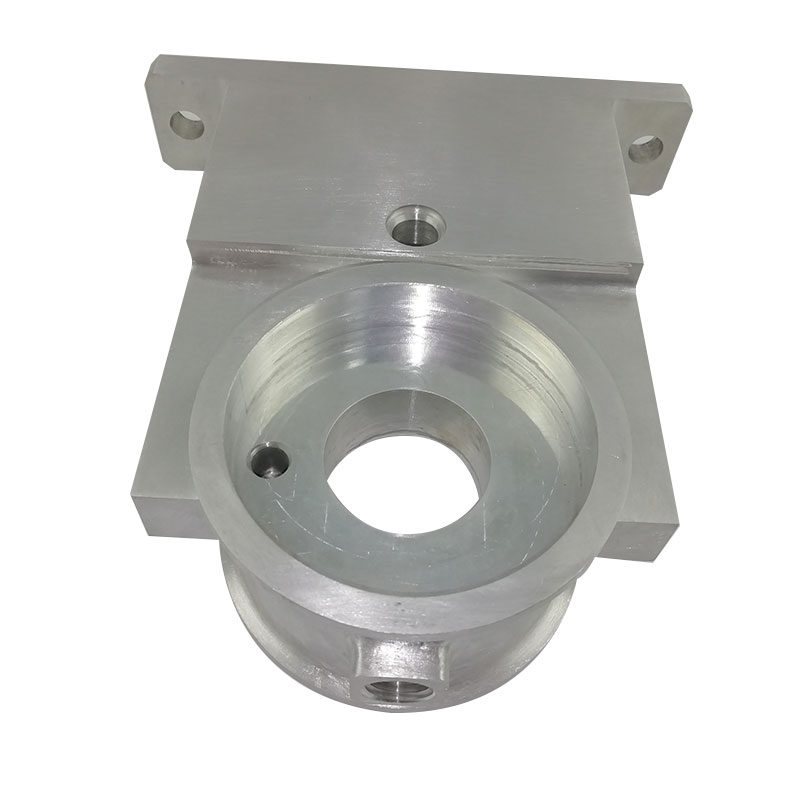

Our business has been focusing on brand strategy. Customers' pleasure is our best advertising. We also offer OEM company for Car Engine Housing Components CNC Machining,Car Engine Housing Parts CNC Milling,Car Engine Housing Products CNC Machining, Our main objectives are to provide our customers worldwide with good quality, competitive price, satisfied delivery and excellent services.

Car Engine Housing Components CNC Machining, As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers, and establish a long term business relationship with buyers and users all over the world.

Hot Products

Tight Tolerance Military Parts CNC Machining

Tight Tolerance Military Parts CNC Machining with more than 10 years in the rapid manufacturing business, Shbury has built up rich experience in CNC machining parts for both prototyping and mass production. we can achieve tight tolerances on CNC machined parts.Motor Shafts Parts CNC Turning

The following is about Motor Shafts Parts CNC Turning.Auto Pipe Joint Parts CNC Machining

One of the top CNC machining service suppliers in Shbury Tech, has been specialized in producing custom CNC turning pipe joints (expansion, welding, clamp) for automobile industry for over 10 years with superior quality and OEM service. Our products of CNC turned and machined pipe joint include zinc, iron, aluminum pipe joint, metal pipe joint, steel, stainless steel, brass pipe joint and other types of CNC lathe machine pipe joint. Reliable auto pipe joints are supplied to consumers with high-precision and stable quality and competitive prices.The following is about auto pipe joint parts CNC machining.High Demand Aerospace Parts CNC Machining

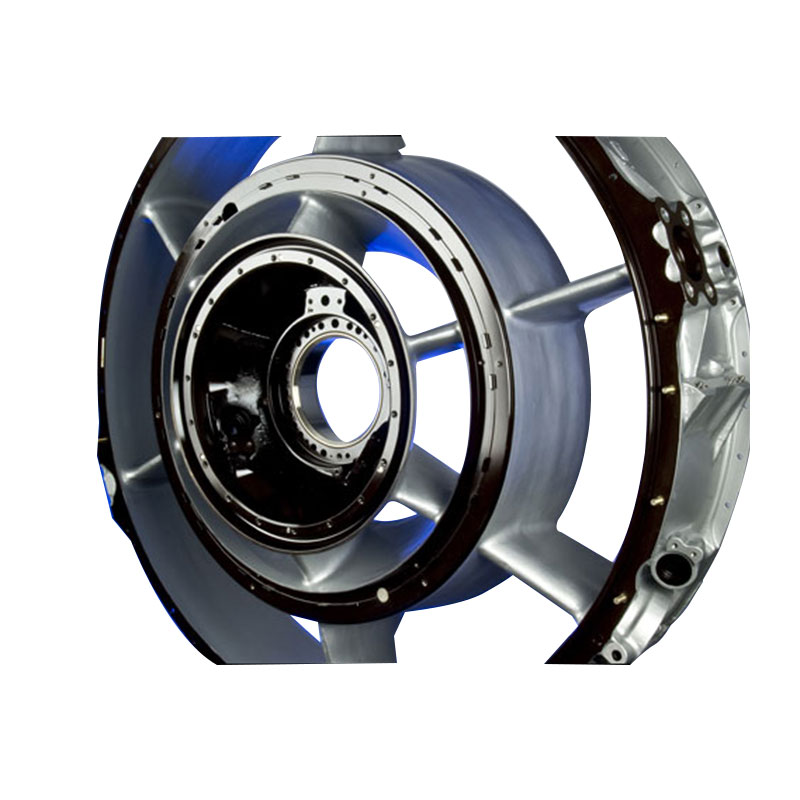

Aluminum alloy high demand aerospace parts CNC Machining has a widely application in many industries, as Aluminum is one of the most commonly used metals which is durable, lightweight, malleable, low cost, and recyclability.Auto Track Hubs Frame Parts CNC Machining

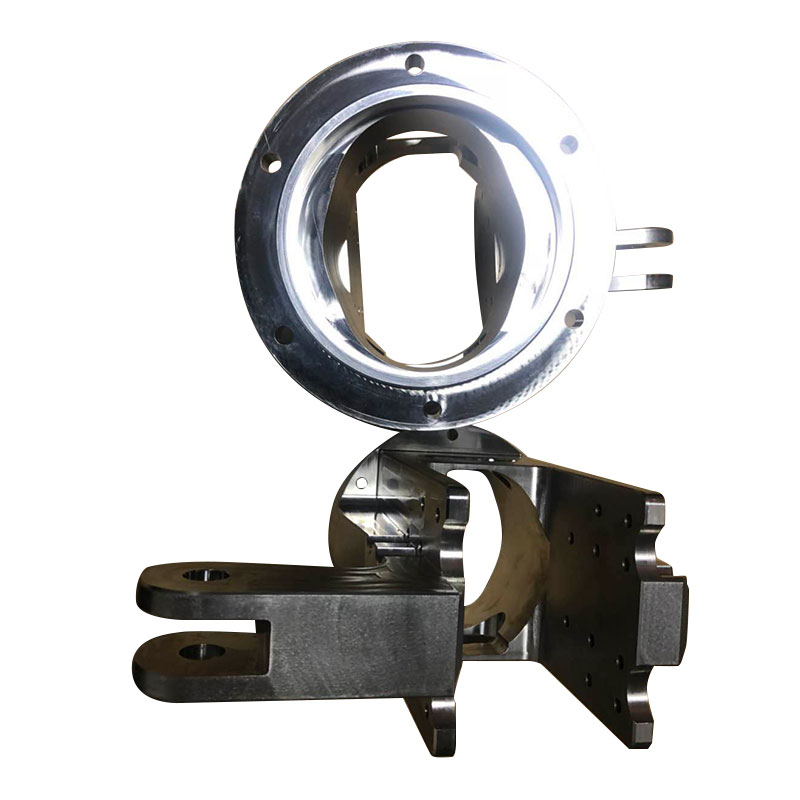

Simple to complex part turning and milling machining services for Automotive industries. For automotive parts and parts machining,Shbury offers the highest degree of OEM service with a basis of 10+ years experience serving the automotive industry. Our automotive precision shop and experts deliver confidence. We have perfected the art of producing large component volumes with complete Shbury reliability, backed by the quality and long-term reliability our customers expect.The following is about auto track hubs frame parts CNC machining.Auto Parts Vacuum Urethane Casting

Vacuum casting technology offers a wide variety of materials to facilitate the creation of cast urethane parts, typically for functional test, pre-production evaluation and low volume production. Cast auto urethane parts are quick and inexpensive without the need to invest any metal tooling when quantities are only dozens of short runs, and can be delivered within weeks in most instances. The following is about Auto Parts Vacuum Urethane Casting.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy