China Cold Rolled Steel Sheet Metal Products Manufacturers, Suppliers, Factory

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Cold Rolled Steel Sheet Metal Products,Cold Rolled Steel Sheet Metal Components,Fixed COLD Carbon Steel Sheet Metal Parts,Repair Cold Carbon Steel Sheet Metal Parts,Stainless steel COLD Carbon Steel Sheet Metal Parts, If you're interested in any of our products and services, make sure you don't be reluctant to call us. We've been wanting to reply you within 24 several hours just after receipt of your respective ask for and to generate mutual un-limited positive aspects and enterprise in in the vicinity of long run.

Cold Rolled Steel Sheet Metal Products, With the superior and exceptional service, we've been well developed along with our customers. Expertise and know-how ensure that we are always enjoying the trust from our customers in our business activities. "Quality", "honesty" and "service" is our principle. Our loyalty and commitments remain respectfully at your service. Contact Us Today For further information, contact us now.

Hot Products

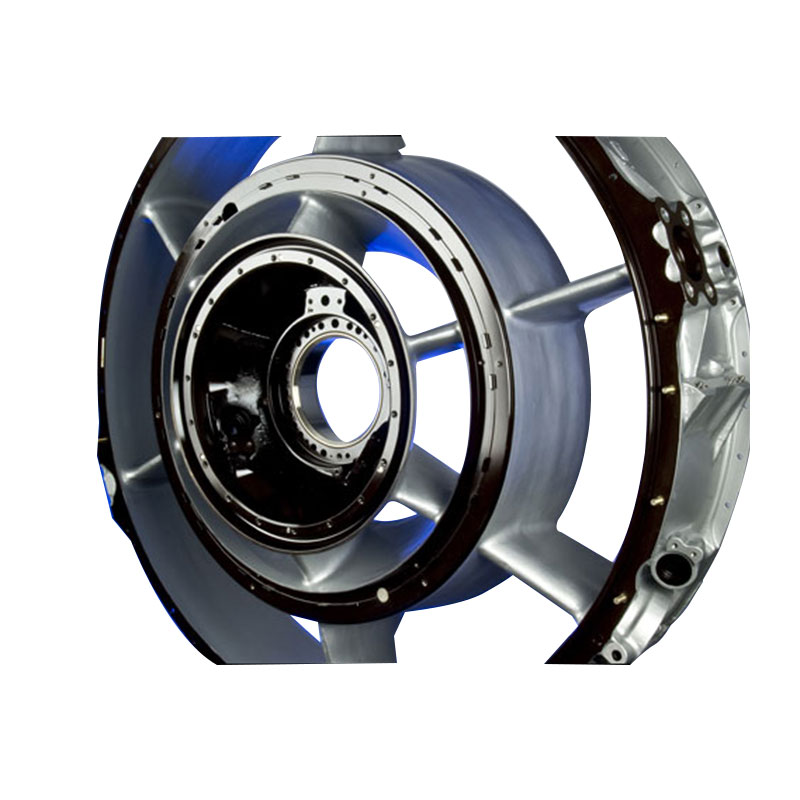

Metal Aerospace Parts CNC Machining

A leader in manufacturing complex details and components for the aerospace industry, shbury provides metal aerospace parts CNC machining. Several in-house processes, including precision CNC turning, CNC milling, lapping and OD grinding are incorporated to fabricate the cnc parts. We also perform in-house deburring and dot peen marking. Outside services sourced to our vendor base include heat treatment and a tungsten carbide plasma spray coating. Tolerance requirements are held to +-0.01mm, a circular run out of +-0.005mm. , Dimensional inspection as well as NDT inspection was done in-house.Plastic Electronic Products CNC Machining

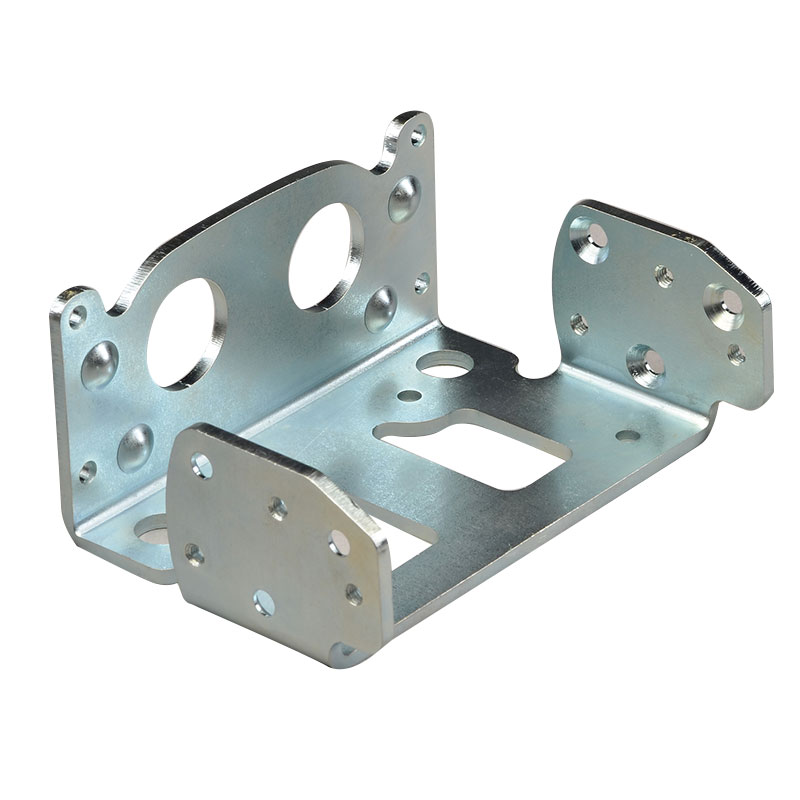

The role of Plastic Electronic Products in the electronics industry has increased exponentially. The continual growth of electronic and engineering devices has led to the designing and manufacturing of various standard and custom plastic products, which can support industrial electronic applications.The following is about Plastic Electronic Products CNC Machining.Auto Throttle Control Shafts Parts CNC Machining

The following is about Auto Throttle Control Shafts Parts CNC Machining.Auto Oil And Gas Rubber Parts Vacuum Casting

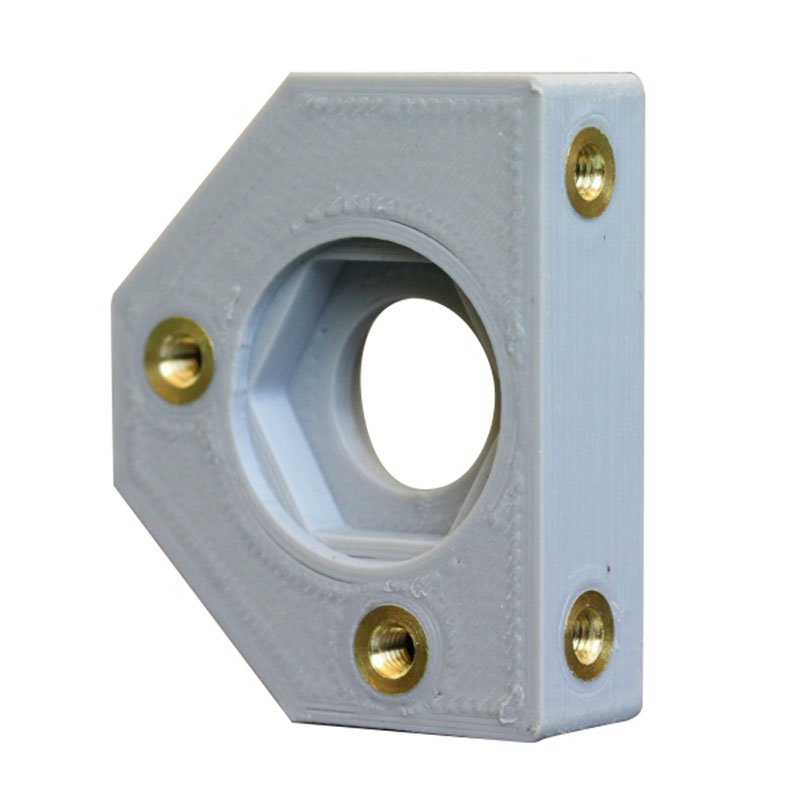

Flexible parts are often referred to colloquially as ‘rubber’ parts. Whilst rubber forms a substantial proportion of them, there are also flexible polyurethanes and thermoplastic elastomers to consider.The following is about Auto Oil And Gas Rubber Parts Vacuum Casting.High Demand Aerospace Parts CNC Machining

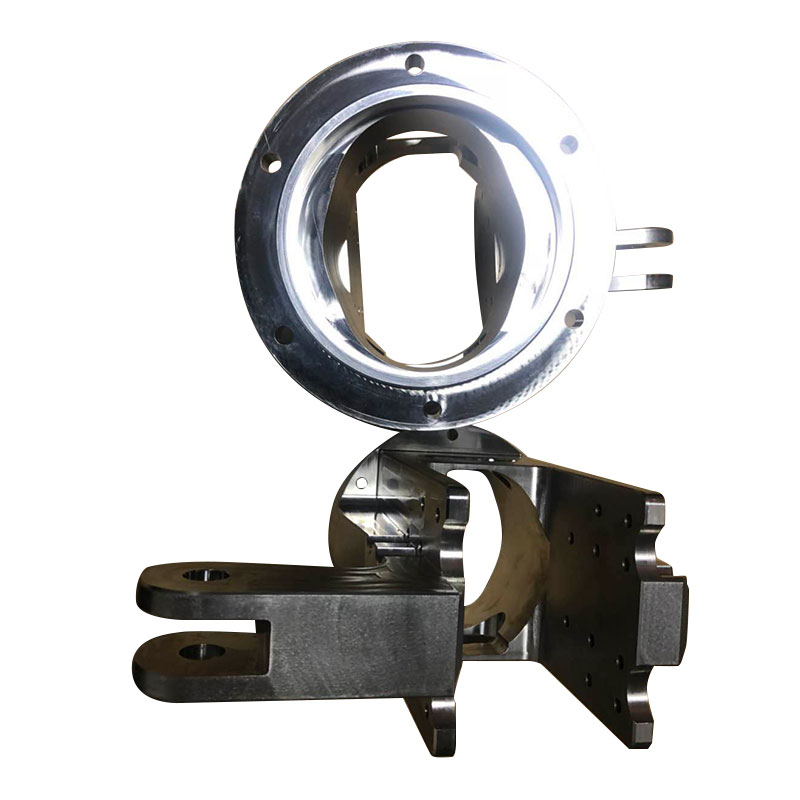

Aluminum alloy high demand aerospace parts CNC Machining has a widely application in many industries, as Aluminum is one of the most commonly used metals which is durable, lightweight, malleable, low cost, and recyclability.Auto Solid Valve Housing Parts CNC Machining

Valve Housing is a key auto valve fitting to assist valve to control the flow of air or liquid through the tube. If your valve in a corrosive environment and the valve housing can't resist corrosion, it will reduce the durability.The inappropriate valve housing and valve fittings will influence valve performance as well.

So, choosing the right valve housing and valve seal material is critical to the running of an automobile valve and the whole system. The core characteristics, materials, properties of the automotive valve housing and application environment should be taken into consideration, including temperature, corrosion possibility, wear characteristics and pressure.The following is about auto solid valve housing parts CNC machining.