China High Demand Aerospace Products CNC Machining Manufacturers, Suppliers, Factory

"Control the standard by the details, show the toughness by quality". Our firm has strived to establish a highly efficient and stable workers workforce and explored an effective high-quality management system for High Demand Aerospace Products CNC Machining,High Demand Aerospace Parts CNC Milling,High Demand Aerospace Components CNC Machining, We now have substantial goods source and also the rate is our advantage. Welcome to inquire about our merchandise.

High Demand Aerospace Products CNC Machining, There are advanced producing & processing equipment and skilled workers to ensure the merchandise with high quality. We now have found an excellent before-sale, sale, after-sale service to ensure the customers that could rest assured to make orders. Until now our goods are now moving on fast and very popular in South America, East Asia, the Middle east, Africa, etc.

Hot Products

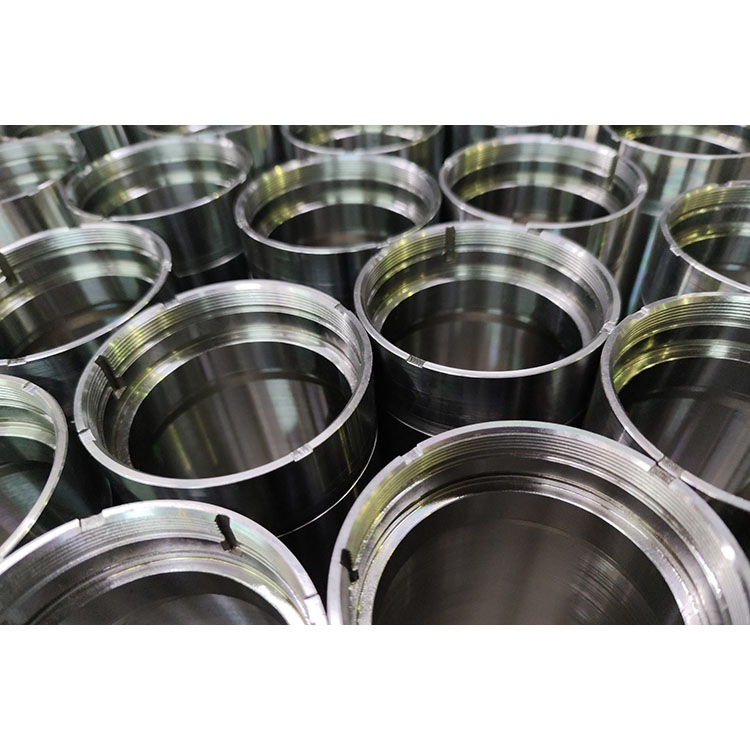

Servo Motor Shaft Aerospace Parts CNC Turning

Servo Motor Shaft is one of the important parts of the motor. It acts as a link between the electromechanical energy conversion between the motor and the device, supporting the rotating parts, transmitting torque and determining the relative position of the rotating parts to the stator.The following is about Servo Motor Shaft Aerospace Parts CNC Turning.Polishing Cast Bronze Brass Copper Casting

China Polishing Cast Bronze Brass Copper Casting Factory Directly Supply. Guoye Optoelectronics is Polishing Cast Bronze Brass Copper Casting manufacturer and supplier in China.Electronic Hookah Nozzle Products CNC Turning

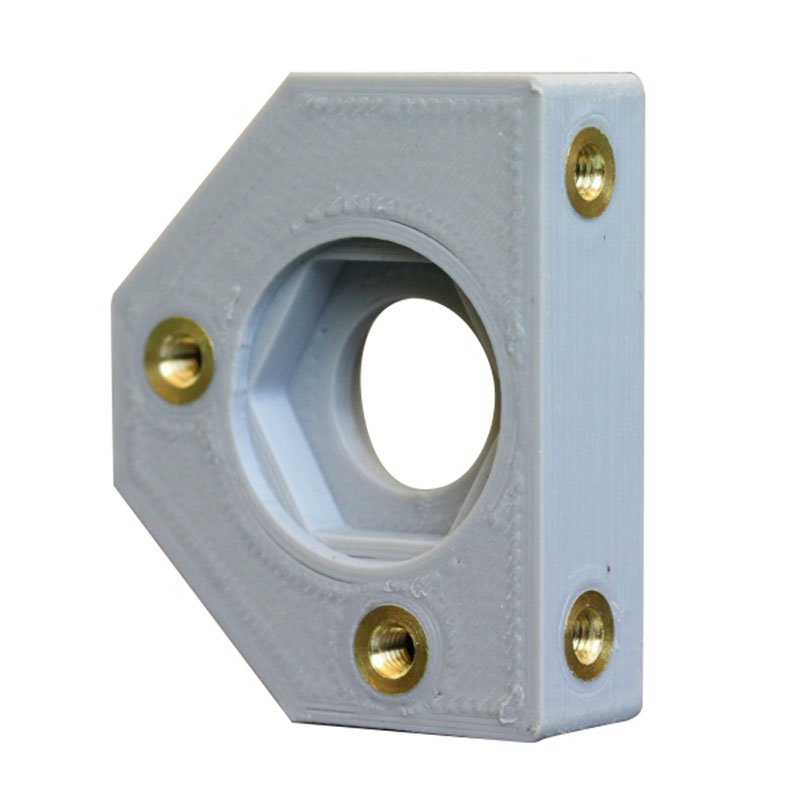

The following is about Electronic Hookah Nozzle Products CNC Turning.Highest Level Military Parts Cnc Machining

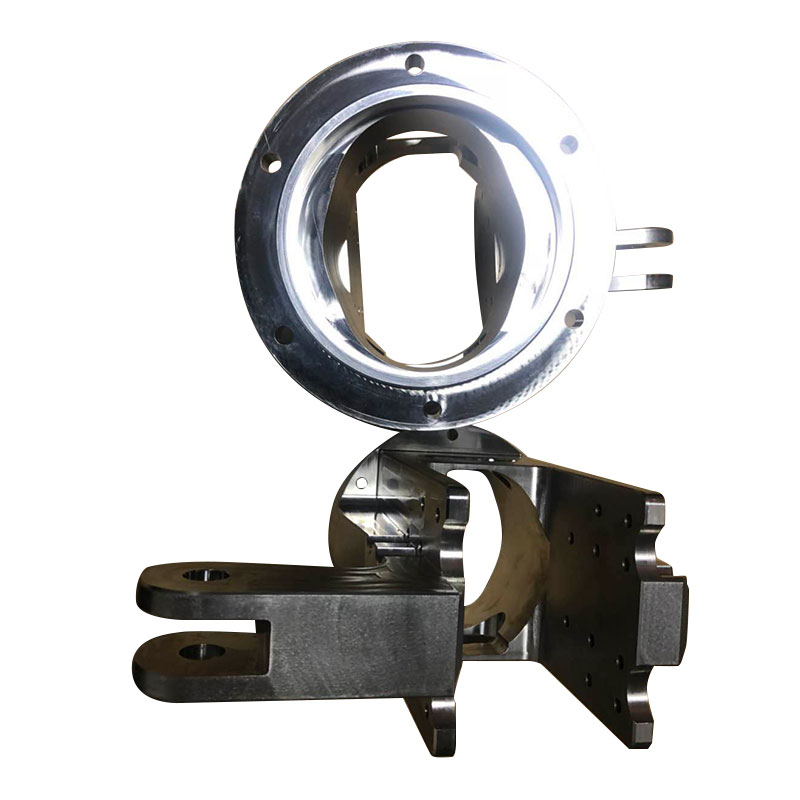

CNC machining service provides a significant manufacturing solution for CNC military parts of a diversity of military and defense equipment, like army equipment, navy equipment, military aircraft, military vehicles, ordnance, ship & submarines, air force equipment, marine corps equipment, coast guard equipment, weapons, etc. To meet the high demands and high standard of military instruments, online Highest Level Military Parts CNC Machining CNC machining , advanced processing technique and sophisticated devices to ensure the high efficiency, high precision, tight tolerance, long service life and outstanding performance of the products.Aluminium Mechanical CNC Machining Parts Anodizing

It's a CNC mill work for aluminium anodizing parts. After cnc machining is complete the part is anodized blue.

Unlike most other finishes, anodizing preserves the natural luster, texture, and beauty of the metal itself. The anodized coating is hard, durable, will never peel, and, under normal conditions, will never wear through. Anodizing is a process for finishing aluminum alloys that employs electrolytic oxidation of the aluminum surface to produce a protective oxide coating. The anodic coating consists of hydrated aluminum oxide and is considered resistant to corrosion and abrasion. Conventional coatings are 0.1 to 1.0 mil thick and are essentially transparent but they may be colored like sample above.The following is about Aluminium Mechanical CNC Machining Parts Anodizing.Cold Carbon Steel Sheet Metal Parts

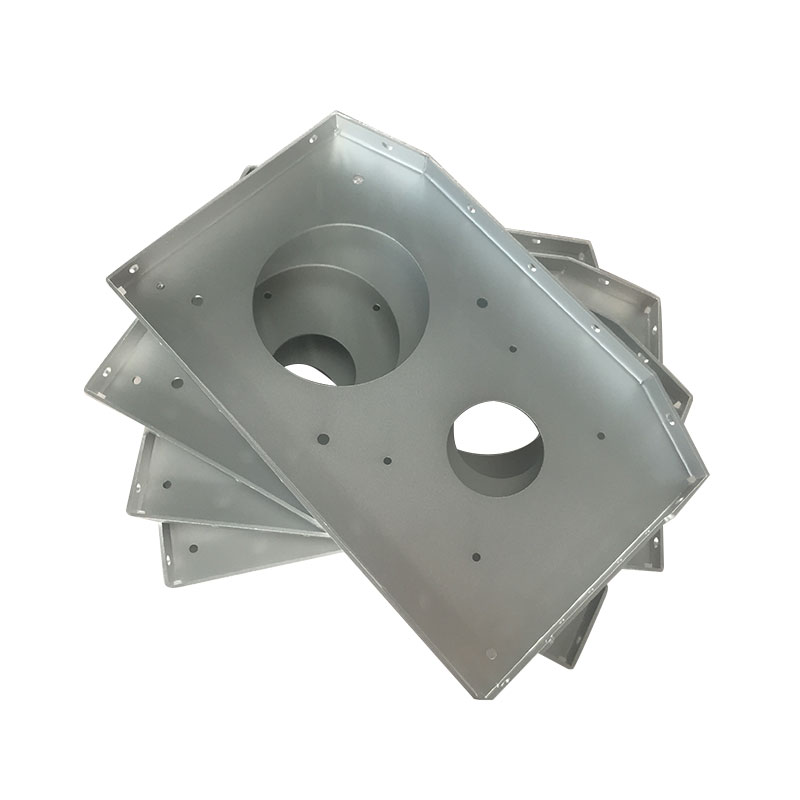

Cold Carbon Steel Sheet Metal Parts