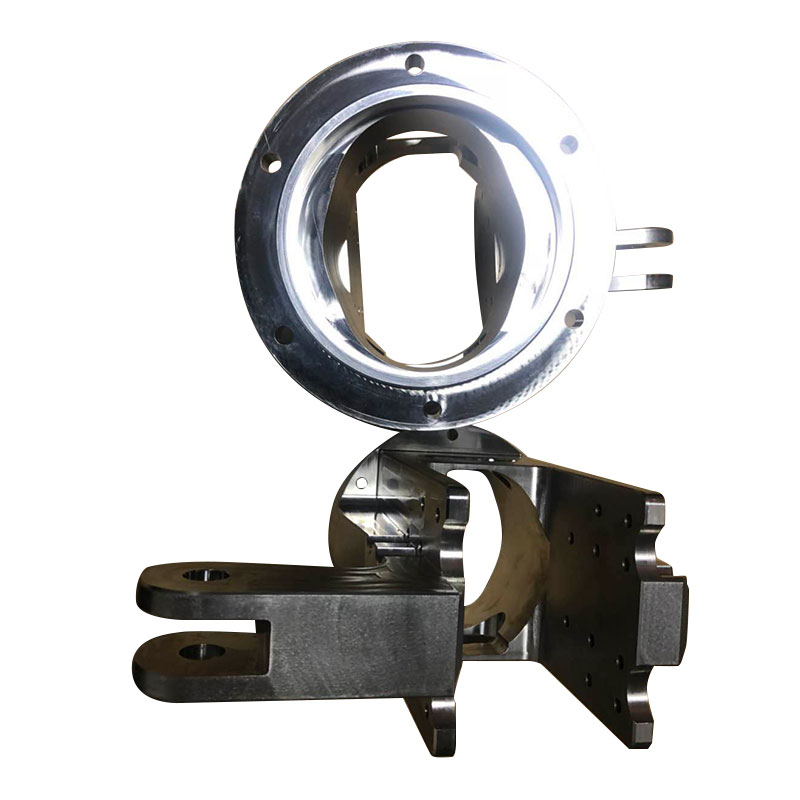

China High Demand Aerospace Parts CNC Milling Manufacturers, Suppliers, Factory

The customer satisfaction is our primary target. We uphold a consistent level of professionalism, quality, credibility and service for High Demand Aerospace Parts CNC Milling,High Demand Aerospace Products CNC Machining,High Demand Aerospace Components CNC Machining, Honesty is our principle, professional operation is our work, service is our goal, and customers' satisfaction is our future!

High Demand Aerospace Parts CNC Milling, Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our items have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

Hot Products

Office Industry Parts Rapid Prototypes

Rapid prototyping uses 3D computer aided design (CAD) and manufacturing processes (typically additive manufacturing) to quickly develop 3D parts, models, or assemblies for research and development and/or product testing.

The use of rapid prototyping techniques allows design teams to develop multiple iterations of a design prototype without the added cost and time using traditional manufacturing and design techniques.The following is about Office Industry Parts Rapid Prototypes.Motor Shafts Parts CNC Turning

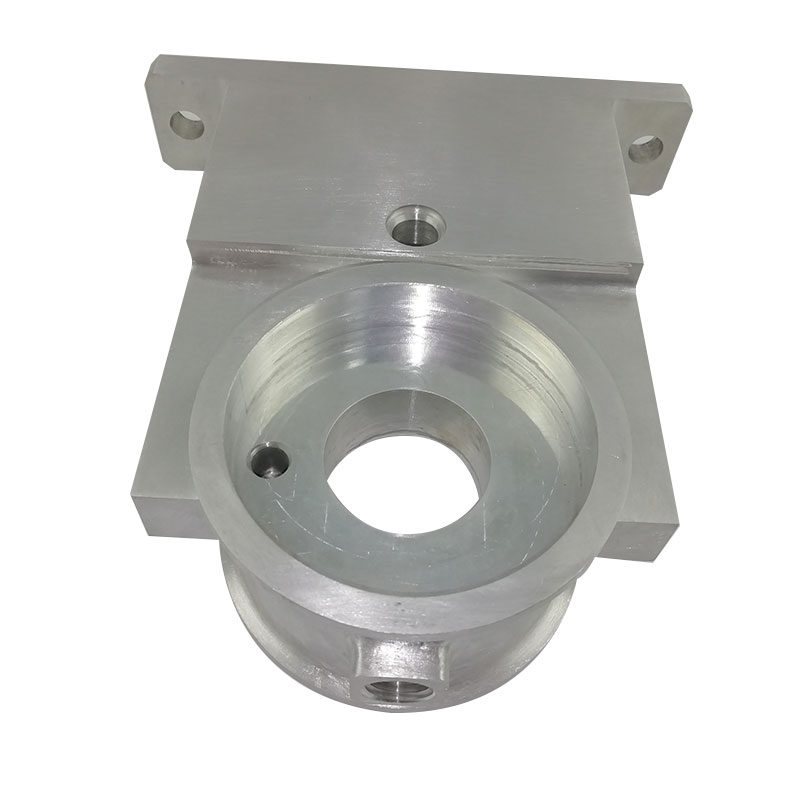

The following is about Motor Shafts Parts CNC Turning.Eco-friendly Low Price CNC Machining Aluminum anodizing Plate Parts

Eco-friendly Low Price CNC Machining Aluminum anodizing Plate Parts:If you need aluminum parts cnc machined we are one of the most capable and affordable sources specializing in manufacturing precision machined parts on advanced cnc machines. With rich knowledge and experience, our cnc machine shop is able to produce parts that require innovative tooling and fixturing in a timely manner with competitive price. We do cnc machining on 4,5 axis all kinds of aluminum with 6061 and 7075 being the most used.Electronic Bushes Products CNC Turning

The following is about Electronic Bushes Products CNC Turning.Mobile Phone Housing Products Vacuum Casting

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

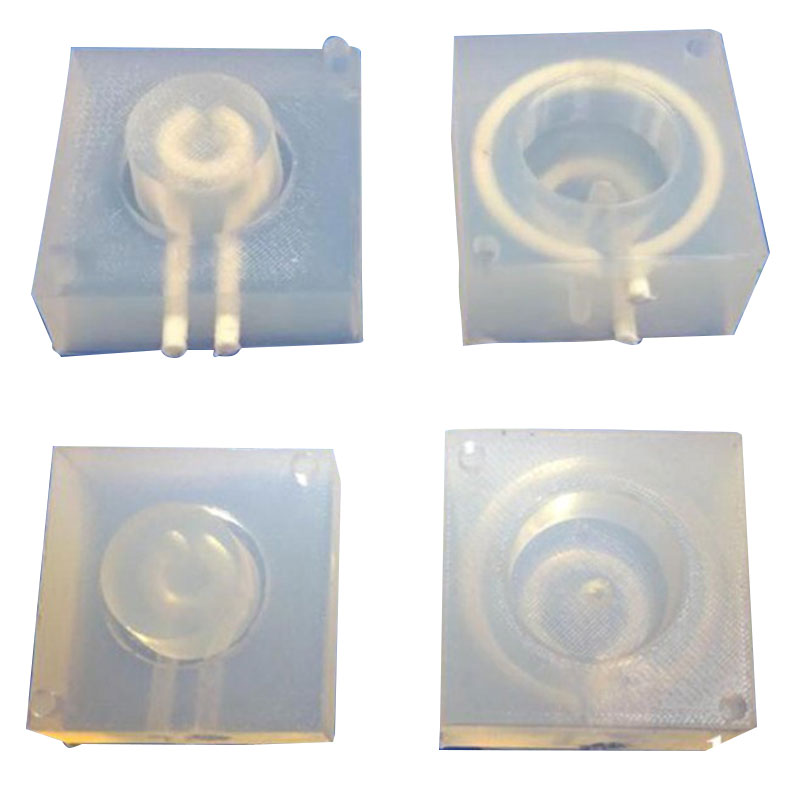

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about mobile phone housing products vacuum casting.Aerospace Gasket Parts Vacuum Casting

Vacuum Casting may be used with a multitude of materials. This method of casting is typically made polyurethane prototype parts in a timely manner. A wide variety of textures, rigidity, strength, hardness or softness may be produced with this manufacturing technique. The parts are usually made with polyurethane resins because it can emulate the texture of other materials. The molds are typically made out of silicone and may even be produced with a 3D printer.The following is about Aerospace Gasket Parts Vacuum Casting.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy