China High Demand Aerospace Products CNC Machining Manufacturers, Suppliers, Factory

"Control the standard by the details, show the toughness by quality". Our firm has strived to establish a highly efficient and stable workers workforce and explored an effective high-quality management system for High Demand Aerospace Products CNC Machining,High Demand Aerospace Parts CNC Milling,High Demand Aerospace Components CNC Machining, We now have substantial goods source and also the rate is our advantage. Welcome to inquire about our merchandise.

High Demand Aerospace Products CNC Machining, There are advanced producing & processing equipment and skilled workers to ensure the merchandise with high quality. We now have found an excellent before-sale, sale, after-sale service to ensure the customers that could rest assured to make orders. Until now our goods are now moving on fast and very popular in South America, East Asia, the Middle east, Africa, etc.

Hot Products

Servo Motor Shaft Aerospace Parts CNC Turning

Servo Motor Shaft is one of the important parts of the motor. It acts as a link between the electromechanical energy conversion between the motor and the device, supporting the rotating parts, transmitting torque and determining the relative position of the rotating parts to the stator.The following is about Servo Motor Shaft Aerospace Parts CNC Turning.Medical X-ray Housing Rapid Prototypes

Optometry device cover for medical deviceThe design process for new or improved medical devices, such as catheters, stents, fluid administration systems, drug delivery systems, chemotherapy tips, syringes, cardio-vascular devices, vascular access devices, etc. includes the important step of producing, examining, and testing a physical medical prototype. Engineers and designers benefit from having a medical prototype to sample its size and get an idea of a its form, fit, and feel.The following is about Medical X-ray Housing Rapid Prototypes.Medical Glucose Meter Device Rapid Prototypes

We offer a complete turnkey solution for creating master patterns and cast copies based on your CAD designs. We not only make high-quality molds but we also offer a full line of finishing services including painting, sanding, pad printing and more. We’ll help you create parts for showroom quality display models, engineering test samples, crowdfunding campaigns and more.The following is about Medical Glucose Meter Device Rapid Prototypes.Electronic Drive Shaft Products CNC Turning

Eccentric shaft refers to the CNC Turning Part whose axis of the outer circle and the outer circle are parallel but not coincident, generally fixed on the rotating shaft of the motor through the eccentric hole. The recess pressure on the eccentric shaft is different, which caused circumferential flow. The CNC machining eccentric hollow shaft is different from the eccentric solid shaft, the diameter of the hollow shaft is more than the solid shaft and require more space. Hollow shafts have a more polar moment of inertia, thus they can transmit more torque compared to solid shafts.The following is about Electronic Drive Shaft Products CNC Turning.Medical Device Fixture CNC Machining

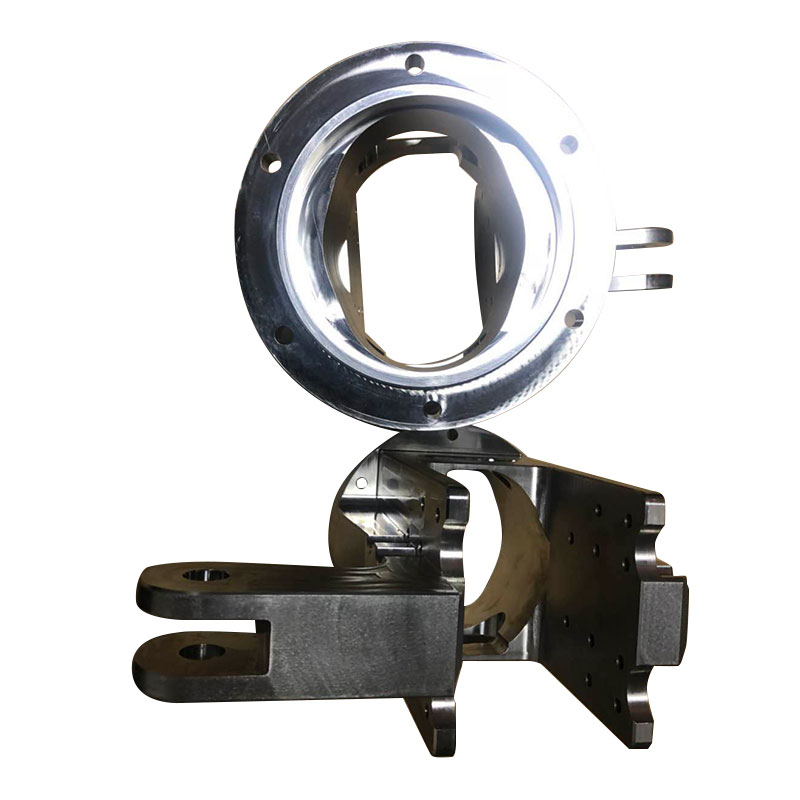

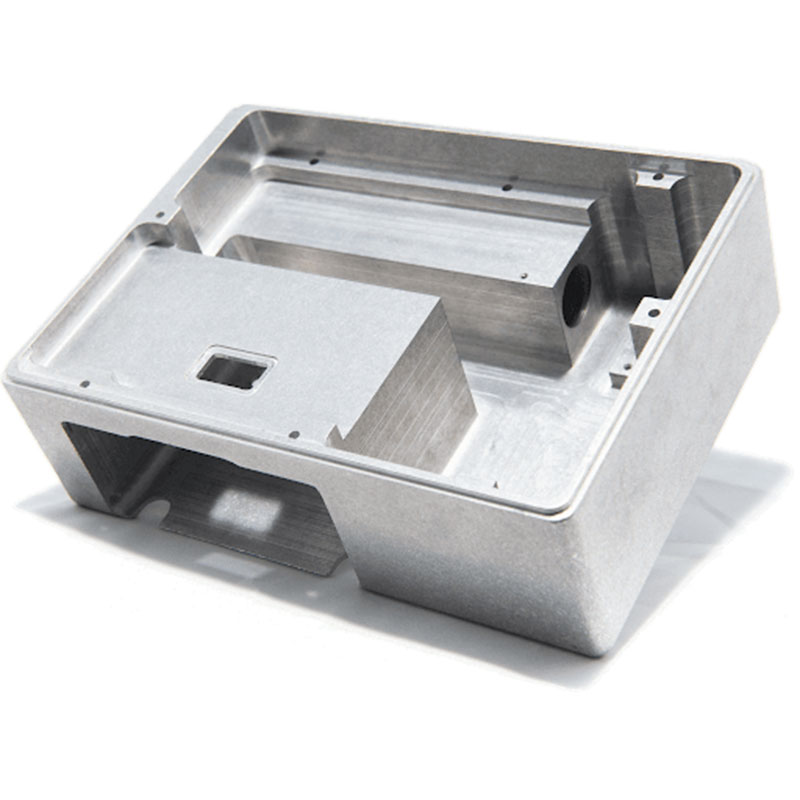

The following is about Medical Device Fixture CNC Machining.Laser Cutting Aluminium Sheet Metal Parts

To cut metal using a laser, a focused laser beam is directed at the material, which is then either melted, burned, vaporized, or blown away by a jet of gas. This cutting method leaves a sleek edge with high quality and a smooth finish.

Compared to mechanical cutting methods, a laser is easier to work with and there is a reduced possibility of contamination. Laser cutting is also more precise than mechanically cutting since the laser cannot wear down. Furthermore, since lasers use localized heat, there is less chance of warping.The following is about Laser Cutting Aluminium Sheet Metal Parts.