China Office Industry Products Rapid Prototypes Manufacturers, Suppliers, Factory

We continuously execute our spirit of ''Innovation bringing development, Highly-quality ensuring subsistence, Management advertising and marketing gain, Credit history attracting buyers for Office Industry Products Rapid Prototypes,Office Industry Components Rapid Prototypes, Our business has already setup a professional, creative and responsible workforce to develop purchasers together with the multi-win principle.

Office Industry Products Rapid Prototypes, We've more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the "client first" principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information remember to do no hesitate to contact us.

Hot Products

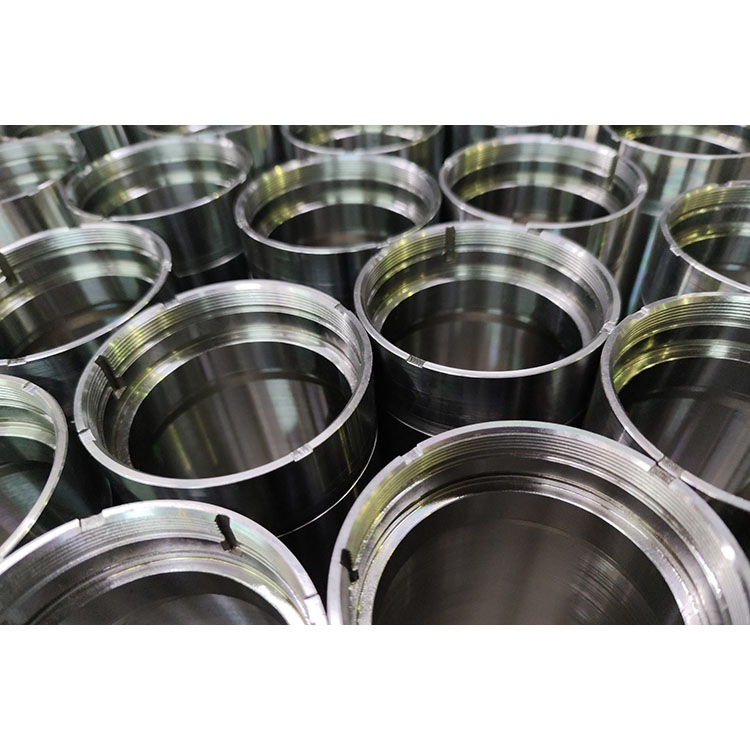

Top Grade Medical Joint Connector CNC Turning

As one of the Top Supplier of CNC Turning service in China, Shbury has the right advanced machines and technical team to manufacture your Joint Connector economically and to your precise specifications, covering OME production for nuts, blots, screws and other Joint Connector parts.The following is about Top Grade Medical Joint Connector CNC Turning.Laser Cutting Auto Parts Rapid Prototypes

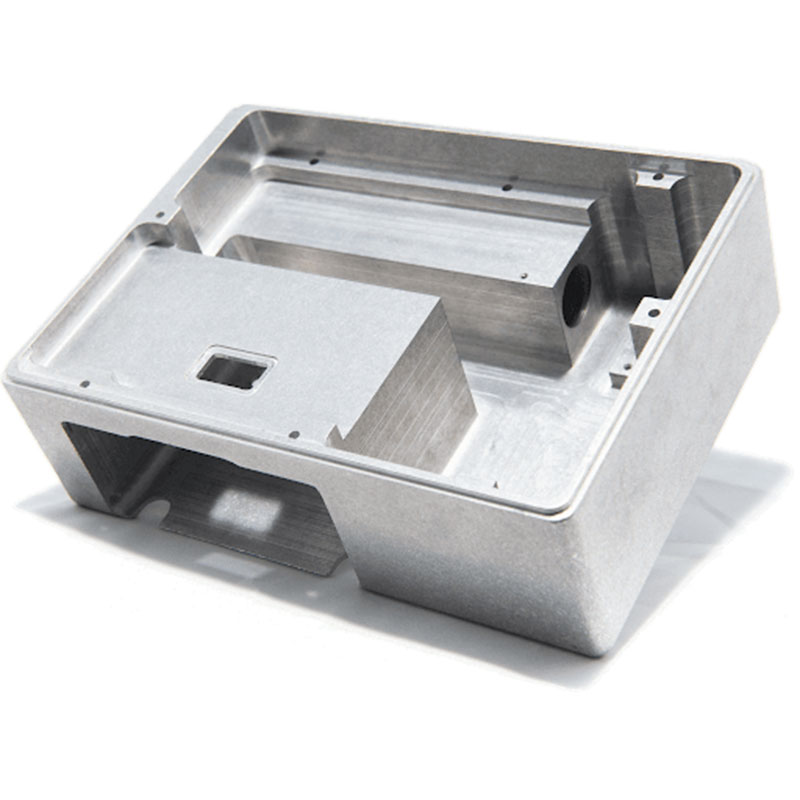

Shbury offers rapid prototyping services for laser cut parts. Laser technology allows us to manufacture parts quickly and cost-effectively, allowing us to provide your team with a precision part prototype quickly and cost-effectively. Using the latest CNC technology, we can use your CAD drawings to produce a part without the delays required to design and manufacture tooling.The following is about Laser Cutting Auto Parts Rapid Prototypes.Military Parts Dowel Pins CNC Turning

We carefully consider the dowel pins material to be used as well as the dowel destination. We take into account the ductility of the destination hole and the ductility of the dowel pins material being used to manufacture the machined parts with accurate dimensions. Regarding size and precision, Alpha Omega Swiss manufactures precision dowel pins to exacting tolerances. We can produce dowel pins to a tolerance of +/- .0001 utilizing stainless steel, tool steel, brass, or aluminum.The following is about Military Parts Dowel Pins CNC Turning.High Precision Medical Device Parts CNC Machining

High Precision Medical Device Parts CNC Machining Shbury is a trusted supplier of medical device parts. Shbury is committed to improving the quality of life for patients and medical staff throughout the industry. Backed by over 10 years of CNC experience, our skilled machinists are able to create a custom medical component with the greatest accuracy possibleMobile Phone Housing Products Vacuum Casting

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about mobile phone housing products vacuum casting.Medical Glucose Meter Device Rapid Prototypes

We offer a complete turnkey solution for creating master patterns and cast copies based on your CAD designs. We not only make high-quality molds but we also offer a full line of finishing services including painting, sanding, pad printing and more. We’ll help you create parts for showroom quality display models, engineering test samples, crowdfunding campaigns and more.The following is about Medical Glucose Meter Device Rapid Prototypes.