China Office Industry Products Rapid Prototypes Manufacturers, Suppliers, Factory

We continuously execute our spirit of ''Innovation bringing development, Highly-quality ensuring subsistence, Management advertising and marketing gain, Credit history attracting buyers for Office Industry Products Rapid Prototypes,Office Industry Components Rapid Prototypes, Our business has already setup a professional, creative and responsible workforce to develop purchasers together with the multi-win principle.

Office Industry Products Rapid Prototypes, We've more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the "client first" principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information remember to do no hesitate to contact us.

Hot Products

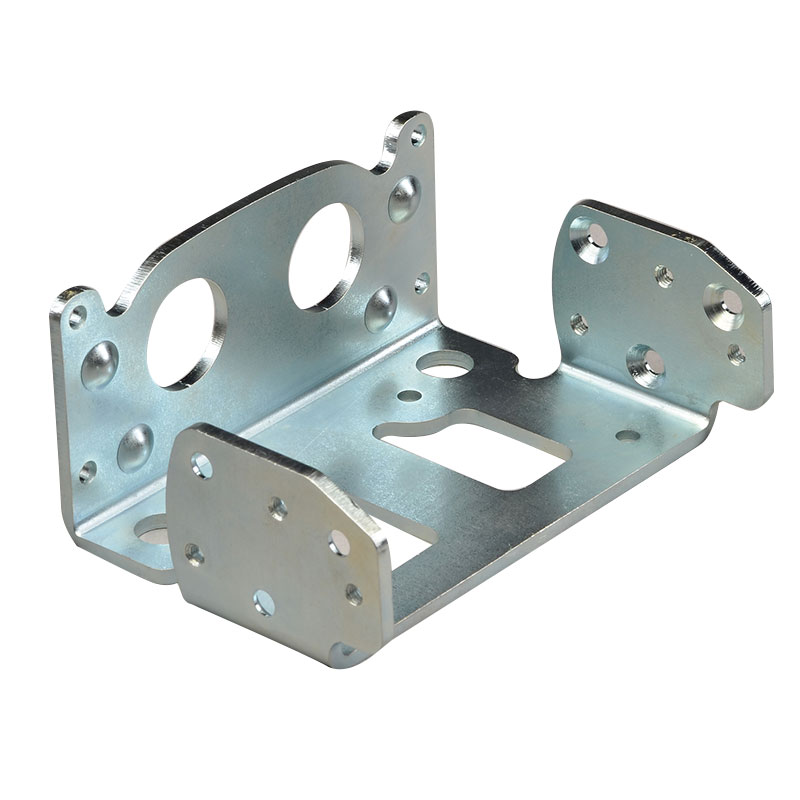

Auminium Sheet Metal Stamping Parts

Take your custom products to the next level with high-grade aluminum sheet metal stampings parts from Shbury. We’re an aluminum stamping factory that will support your vision by providing custom aluminum parts tailored to your unique project. Thanks to our industry-leading in-house tooling capabilities and favorable lead times, you can trust that we will deliver on time and on budget.

At Shbury we don’t take a cookie-cutter approach to any of our partnerships. Our tooling is completely customized and we’re able to meet your exact manufacturing needs through extensive list of value added services.The following is about auminium sheet metal stamping parts.Precision Aerospace Parts CNC Machining

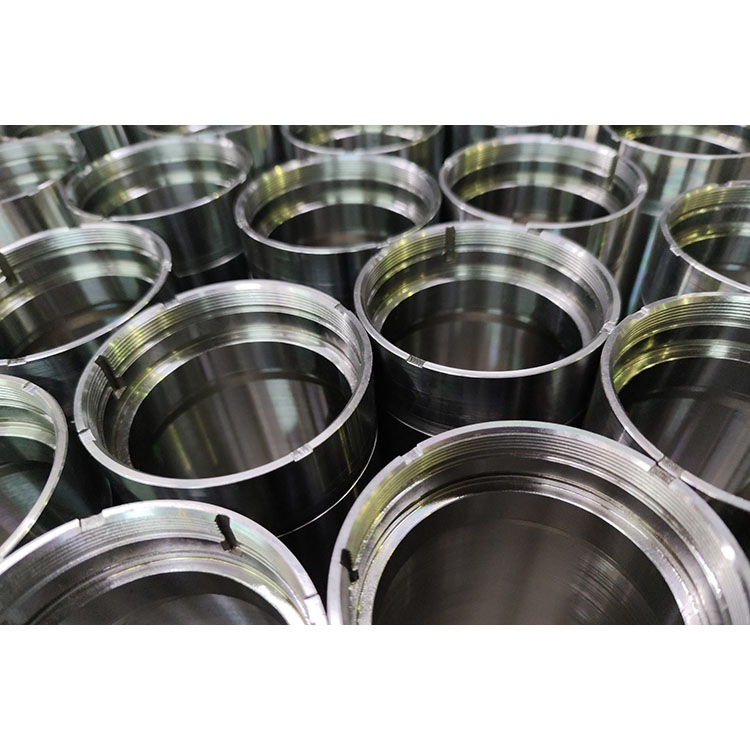

Precision aerospace parts CNC machining need durable material, strict specification standard, batch traceability and more requirements to create premium airplane body and parts to ensure excellent performance and definite safety.Electronic Nozzle Products Cnc Turning

CNC aluminum tubes/pipe also known as the CNC machine nozzle, have the characteristics of corrosion resistance and lightweight, and are widely used in various industries, such as automobiles, aerospace, aviation, electronics industry, agriculture, electromechanical and so on. Aluminum pipes/tubes are ubiquitous in our life. But it’s most commonly used for shisha/hookah, tattoo or e-cigarette.The following is about Electronic Nozzle Products CNC Turning.Aircraft Seat Frame Parts Rapid Prototypes

Innovative prototypes from aerospace engineering workshops are already in flight today. Rapid prototyping is already being used to produce specific aircraft interior components such as air ducts, armrests, seat frames end caps, seat framework and wall panels. Prototyping will be an integral piece of the manufacturing and new part development processes for years to come. The prototypes from aerospace engineering will without a doubt be at the center of space exploration as well as the coming transportation revolution.The following is about Aircraft Seat Frame Parts Rapid Prototypes.Indirectly Human Medical Device Parts CNC Machining

The following is about Indirectly Human Medical Device Parts CNC Machining.Cold Carbon Steel Sheet Metal Parts

Cold Carbon Steel Sheet Metal Parts