China Smart Mechanical Components Vacuum Casting Manufacturers, Suppliers, Factory

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Smart Mechanical Components Vacuum Casting,Smart Mechanical Products Vacuum Casting, Therefore, we could satisfy different inquiries from different clients. Remember to come across our web site to check additional facts from our items.

Smart Mechanical Components Vacuum Casting, Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

Hot Products

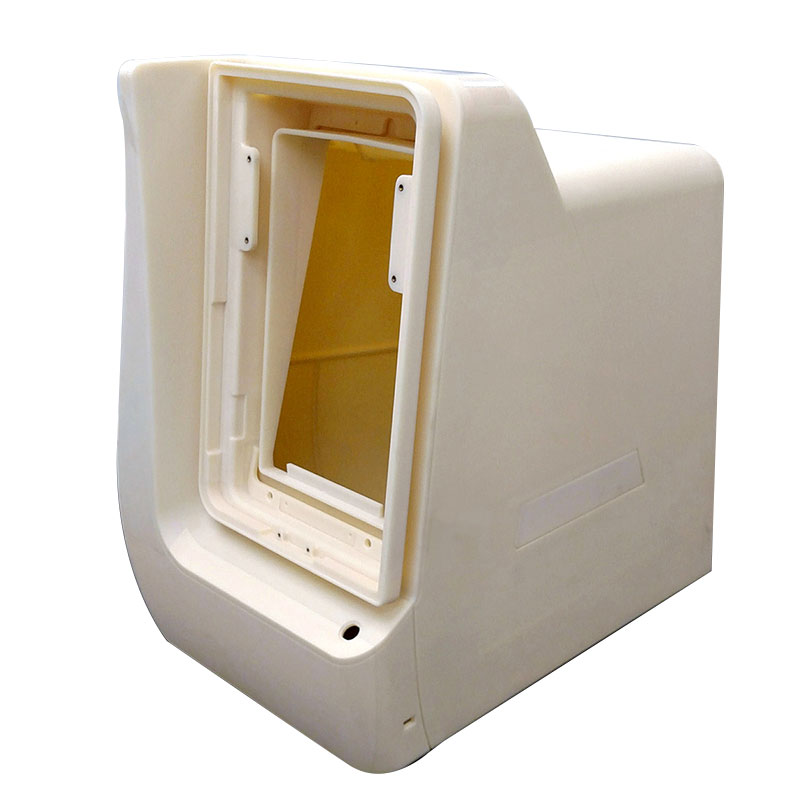

Medical Device Plastic Housing Vacuum Casting

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about medical device plastic housing vacuum casting.Aerospace Seal Parts Vacuum Casting

Silicone is cheaper in terms of cost compared to the injection mold. The reason for this difference in cost, is the nature of injection mold, being built on steel or aluminum parts. The cost if silicone mold can be from hundreds to thousands while the injection one will range from thousands to tens of thousands.The following is about Aerospace Seal Parts Vacuum Casting.Laser Cutting Auto Parts Rapid Prototypes

Shbury offers rapid prototyping services for laser cut parts. Laser technology allows us to manufacture parts quickly and cost-effectively, allowing us to provide your team with a precision part prototype quickly and cost-effectively. Using the latest CNC technology, we can use your CAD drawings to produce a part without the delays required to design and manufacture tooling.The following is about Laser Cutting Auto Parts Rapid Prototypes.Mechanical Connectors Parts CNC Turning

Mechanical Connectors Parts, including the Joint Connector Nuts, Joint Connector Blots, Joint Connector Screws, are mechanical connectors which used to link between two structures, connect parts or components together similar to fasteners.The following is about Mechanical Connectors Parts CNC Turning.Auto Throttle Control Shafts Parts CNC Machining

The following is about Auto Throttle Control Shafts Parts CNC Machining.Top Grade Medical Joint Connector CNC Turning

As one of the Top Supplier of CNC Turning service in China, Shbury has the right advanced machines and technical team to manufacture your Joint Connector economically and to your precise specifications, covering OME production for nuts, blots, screws and other Joint Connector parts.The following is about Top Grade Medical Joint Connector CNC Turning.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy