China Titanium Aerospace Parts CNC Milling Manufacturers, Suppliers, Factory

We emphasize advancement and introduce new products and solutions into the market each year for Titanium Aerospace Parts CNC Milling,Titanium Aerospace Products CNC Machining,Titanium Aerospace Components CNC Machining, The main purpose of our company is always to live a satisfactory memory to many of the customers, and establish a lengthy time period enterprise romantic relationship with prospective buyers and users all over the environment.

Titanium Aerospace Parts CNC Milling, we have now complete material production line, assembling line , quality control system, and the most importantly, we now have many patents technology and experienced technical&production team, expert sales service team. With all those advantages, we're about to create"the reputable international brand of nylon monofilaments", and spreading our solutions to every corner of the world. We've been keep moving and try our best to serve our customers.

Hot Products

Aerospace Couplers Parts CNC Turning

Aerospace Couplers Parts CNC Turning Services With a view to produce superior products for customers, Shbury actively introduced advanced automatic machines. Currently there are several brand-new CNC automatic lathes, automatic secondary processors and other semi-automatic precise machines. Through the smooth operation of the qualified engineers, our products are more stable in quality and efficient of capacity. we are equipped with 10 precision CNC automatic lathes from Japan, as well as a series of precision measuring and QC inspection instruments. we are able to steadily improve technological know-how, lower defective rates, which already helped us to build a solid reputation.Medical Y Joint Connector CNC Turning

Joint Connectors, including the Joint Connector Nuts, Joint Connector Blots, Joint Connector Screws, are mechanical connectors which used to link between two structures, connect parts or components together similar to fasteners. In Mechanical industry, the assembly of any equipment and machine is inseparable from the joint connecter parts, so connectors in different materials (brass, steel, aluminum, alloy, plastic and other metal) are mass-produced to meet different industrial needs. To meet the high quality, sturdy and precise production standards, CNC machining service for Joint Connectors are applied.The following is about Medical Y Joint Connector CNC Turning.E-cigarette Aluminium Tube Products CNC Turning

The following is about E-cigarette Aluminium Tube Products CNC Turning.Medical Infusion Pump Housing Rapid Prototypes

We offer a complete turnkey solution for creating master patterns and cast copies based on your CAD designs. We not only make high-quality molds but we also offer a full line of finishing services including painting, sanding, pad printing and more. We’ll help you create parts for showroom quality display models, engineering test samples, crowdfunding campaigns and more.The following is about Medical Infusion Pump Housing Rapid Prototypes.High Demand Aerospace Parts CNC Machining

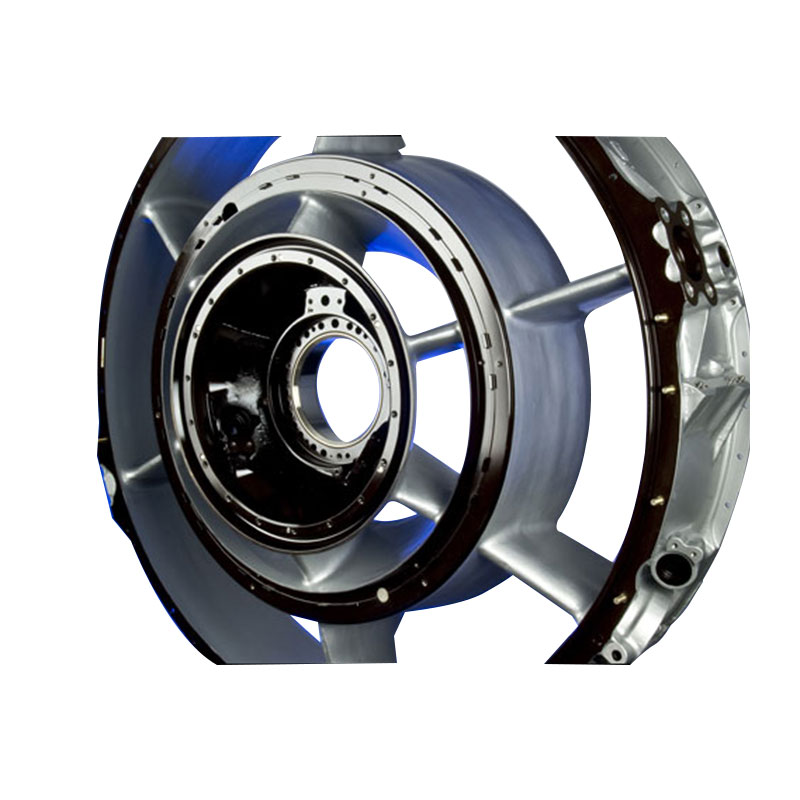

Aluminum alloy high demand aerospace parts CNC Machining has a widely application in many industries, as Aluminum is one of the most commonly used metals which is durable, lightweight, malleable, low cost, and recyclability.Robotic Mechanical Parts CNC Machining

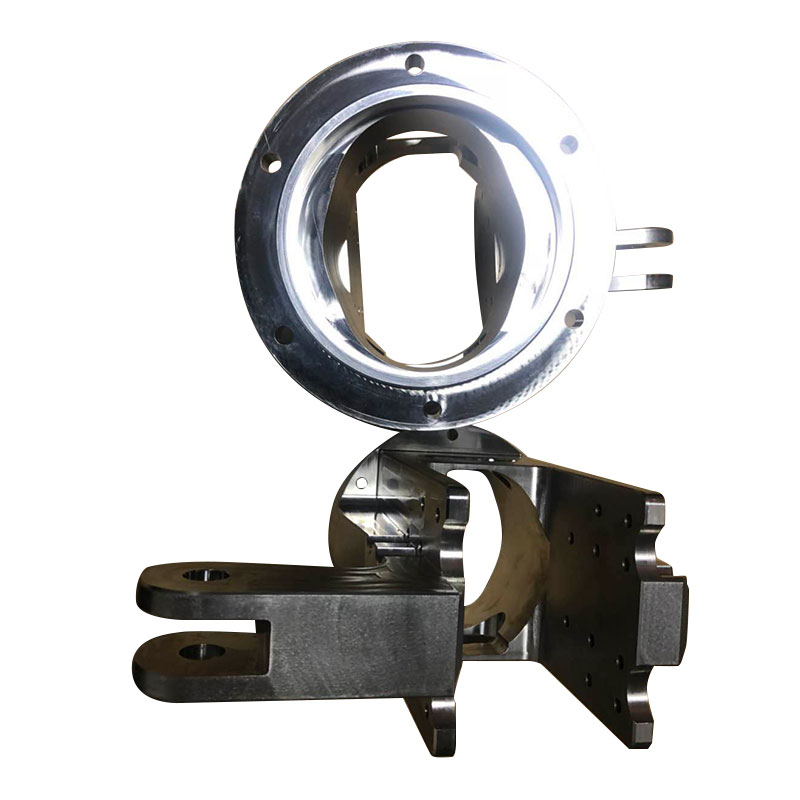

Firstly, parts for robotic applications often have a requirement to be strong, tough and lightweight. Materials such as aluminium have ideal characteristics and can easily be machined using CNC Machining.

Similarly POM (also known as Delrin and Acetal) is commonly used for robotic mechanical cnc machining parts. Easy to machine, it is known for its low friction, high stiffness and superior dimensional stability. As a low-cost plastic, it is also a very economical option.The following is about robotic mechanical parts CNC machining.