China Titanium Aerospace Components CNC Machining Manufacturers, Suppliers, Factory

Our solutions are broadly acknowledged and dependable by users and may meet consistently developing economic and social requires for Titanium Aerospace Components CNC Machining,Titanium Aerospace Parts CNC Milling,Titanium Aerospace Products CNC Machining, Thanks for taking your useful time to go to us and look ahead to have a nice cooperation with you.

Titanium Aerospace Components CNC Machining, Meanwhile, we're building up and consummating triangle market & strategic cooperation in order to achieve a multi-win trade supply chain to expand our market vertically and horizontally for a brighter prospects. development. Our philosophy is to create cost-effective products and solutions, promote perfect services, cooperate for long-term and mutual benefits, firm a comprehensive mode of excellent suppliers system and marketing agents, brand strategic cooperation sales system.

Hot Products

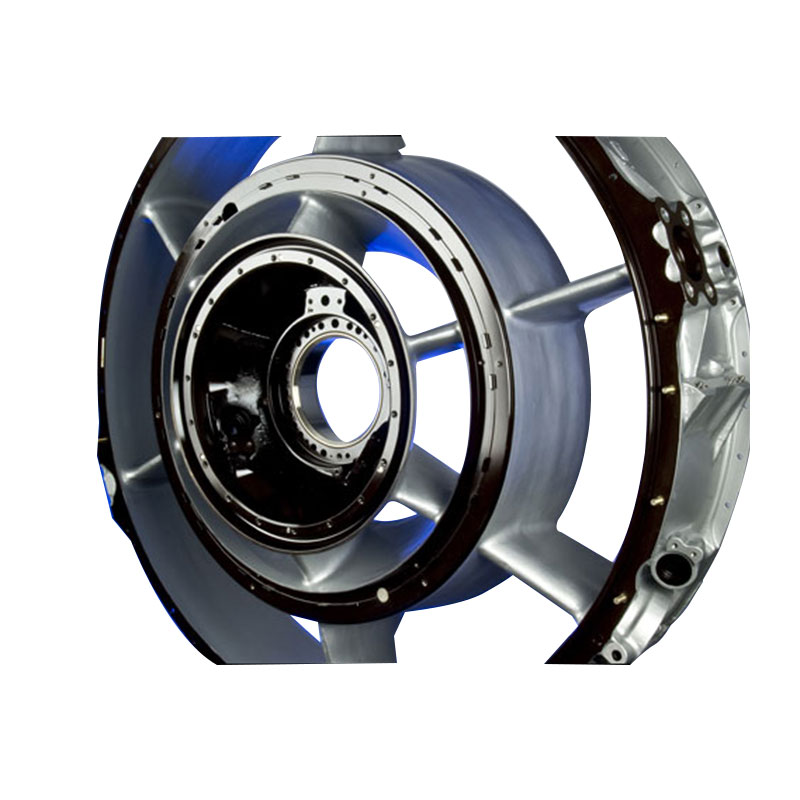

Aerospace Couplers Parts CNC Turning

Aerospace Couplers Parts CNC Turning Services With a view to produce superior products for customers, Shbury actively introduced advanced automatic machines. Currently there are several brand-new CNC automatic lathes, automatic secondary processors and other semi-automatic precise machines. Through the smooth operation of the qualified engineers, our products are more stable in quality and efficient of capacity. we are equipped with 10 precision CNC automatic lathes from Japan, as well as a series of precision measuring and QC inspection instruments. we are able to steadily improve technological know-how, lower defective rates, which already helped us to build a solid reputation.Auto Solid Valve Housing Parts CNC Machining

Valve Housing is a key auto valve fitting to assist valve to control the flow of air or liquid through the tube. If your valve in a corrosive environment and the valve housing can't resist corrosion, it will reduce the durability.The inappropriate valve housing and valve fittings will influence valve performance as well.

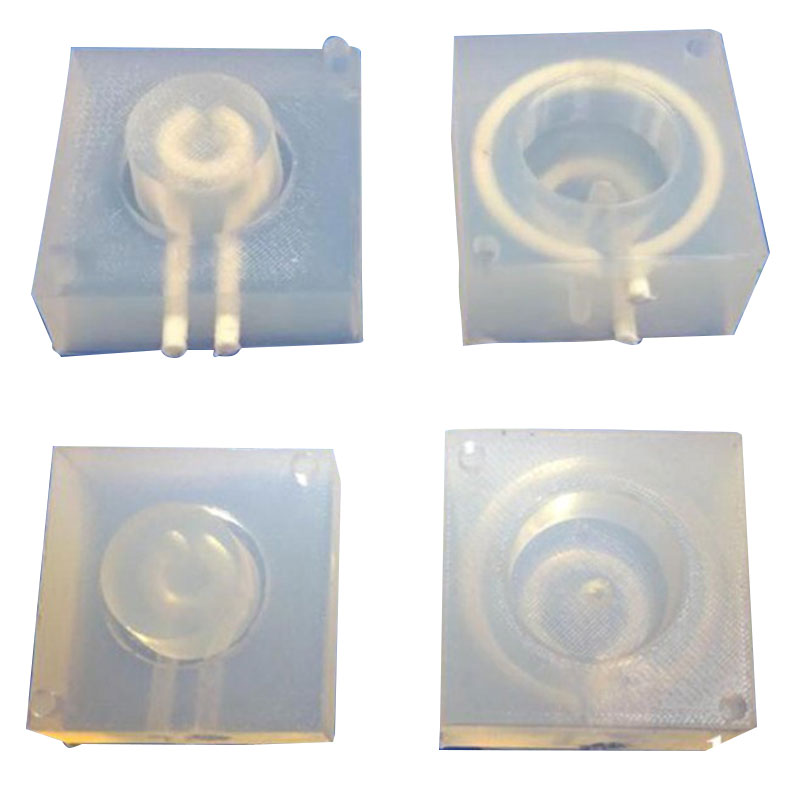

So, choosing the right valve housing and valve seal material is critical to the running of an automobile valve and the whole system. The core characteristics, materials, properties of the automotive valve housing and application environment should be taken into consideration, including temperature, corrosion possibility, wear characteristics and pressure.The following is about auto solid valve housing parts CNC machining.Mechanical Retainer Rings CNC Turning

The following is about Mechanical Retainer Rings CNC Turning.Aluminum Sheet Metal Fabrication

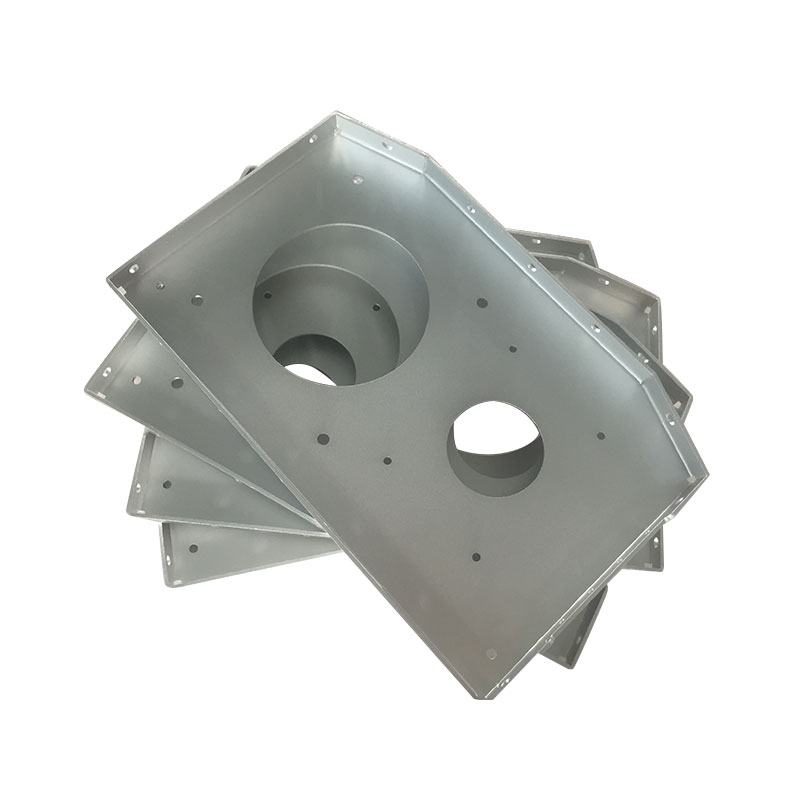

Aluminum is a very common metal utilized at Shbury to manufacture various OEM products for wide-ranging applications: on-highway vehicle doors/body panels, medical equipment, medical carts, energy dispensing stations, digital display, and variable messaging controls, consumer products, kiosks, various enclosures, and countless other parts. The following is about aluminum sheet metal fabrication.Galvanized Steel Sheet Metal Bending Parts

Galvanized steel sheet metal bending parts or galvanealed steel, which is galvanized then annealed.

Galvanization is the process of applying a protective zinc coating to steel in order to prevent rust and corrosion. Annealing is a heat treatment process that alters the microstructure of a material to change its mechanical or electrical properties, typically reducing the hardness and increasing the ductility for easier fabrication.Electronic Bushes Products CNC Turning

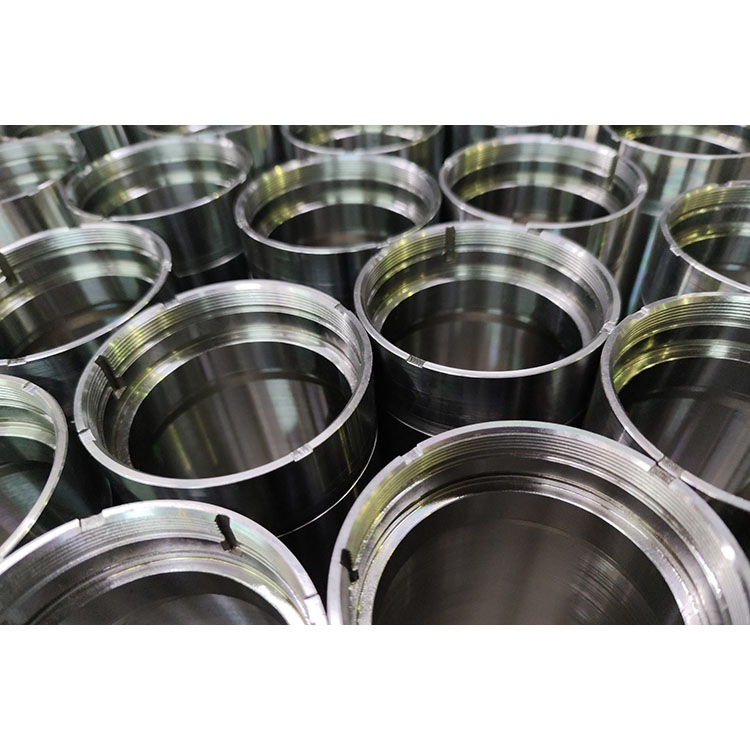

The following is about Electronic Bushes Products CNC Turning.