China Aluminium Anodizing Military Components CNC Turning Manufacturers, Suppliers, Factory

abide by the contract, conforms into the market requirement, joins while in the market competition by its high quality as well as provides much more comprehensive and exceptional assistance for consumers to let them develop into significant winner. The pursue in the company, will be the clients' satisfaction for Aluminium Anodizing Military Components CNC Turning,Aluminium Anodizing Military Products CNC Turning, On account of superior excellent and aggressive rate , we will be the sector leader, make sure you don’t hesitate to contact us by cellular phone or email, if you're fascinated in almost any of our items.

Aluminium Anodizing Military Components CNC Turning, now we have 8 years experience of production and 5 years experience in trading with the customers all over the world. our clients mainly distributed in the North America, Africa and Eastern Europe. we can supply high quality items with the very competitive price.

Hot Products

Aerospace Seal Parts Vacuum Casting

Silicone is cheaper in terms of cost compared to the injection mold. The reason for this difference in cost, is the nature of injection mold, being built on steel or aluminum parts. The cost if silicone mold can be from hundreds to thousands while the injection one will range from thousands to tens of thousands.The following is about Aerospace Seal Parts Vacuum Casting.Auto Throttle Control Shafts Parts CNC Machining

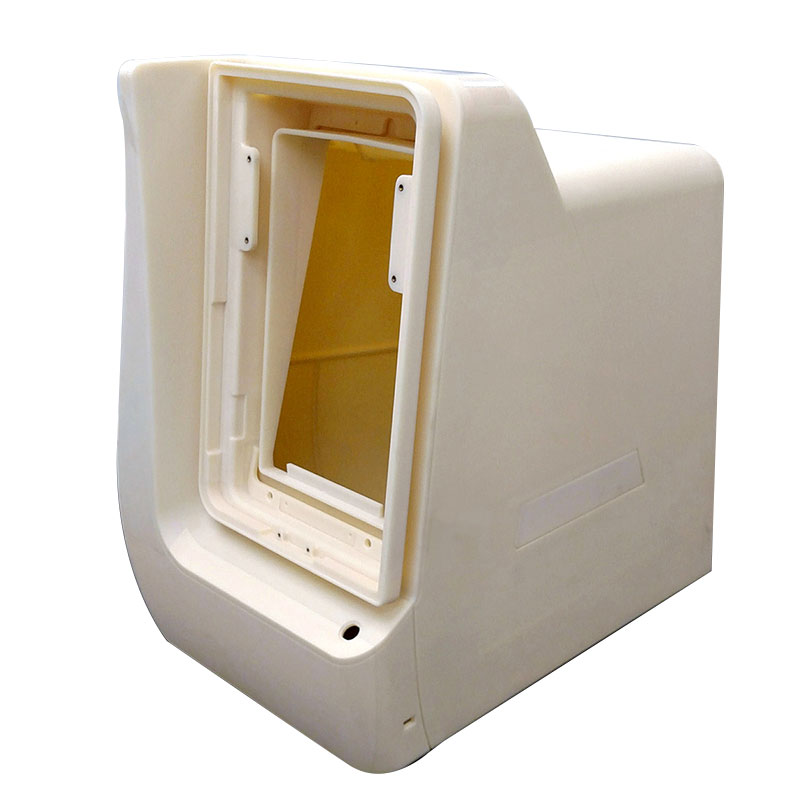

The following is about Auto Throttle Control Shafts Parts CNC Machining.Medical ECG Device Shell CNC Machining

The following is about Medical ECG Device Shell CNC Machining.Laser Cutting Aluminium Sheet Metal Parts

To cut metal using a laser, a focused laser beam is directed at the material, which is then either melted, burned, vaporized, or blown away by a jet of gas. This cutting method leaves a sleek edge with high quality and a smooth finish.

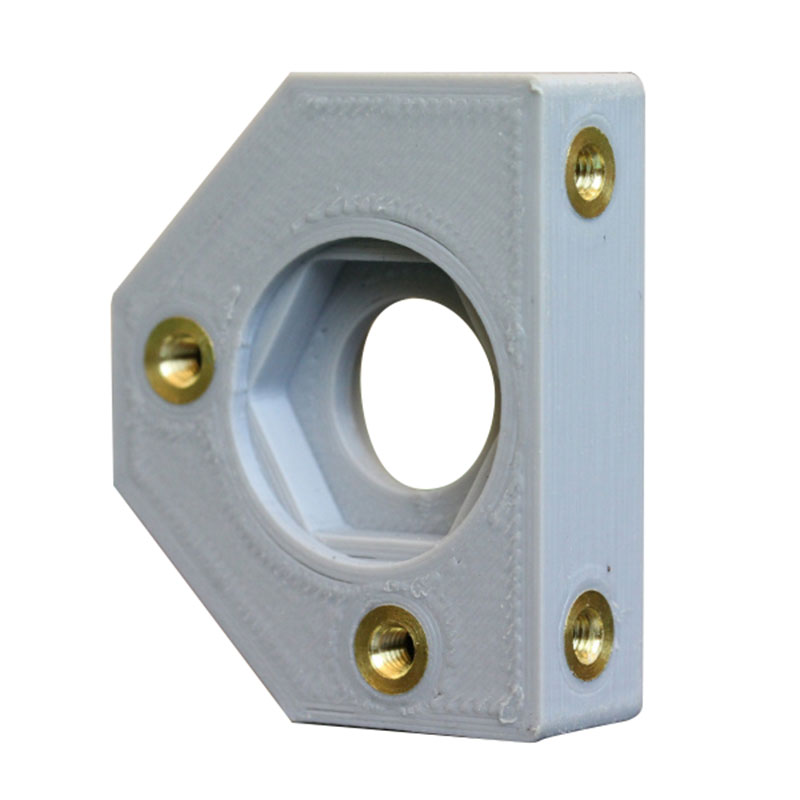

Compared to mechanical cutting methods, a laser is easier to work with and there is a reduced possibility of contamination. Laser cutting is also more precise than mechanically cutting since the laser cannot wear down. Furthermore, since lasers use localized heat, there is less chance of warping.The following is about Laser Cutting Aluminium Sheet Metal Parts.Brass Inserts Plastic Electronic Products Vacuum Casting

Shbury has a fully equipped Vacuum Casting suite with multiple vacuum casting machines. We also have 3D printing facilities which are used for producing the master pattern. For best quality, we use high definition SLA models.The following is about Brass Inserts Plastic Electronic Products Vacuum Casting.Indirectly Human Medical Device Parts CNC Machining

The following is about Indirectly Human Medical Device Parts CNC Machining.