China Aluminum Sheet Metal Parts Sheet Metal Fabrication Manufacturers, Suppliers, Factory

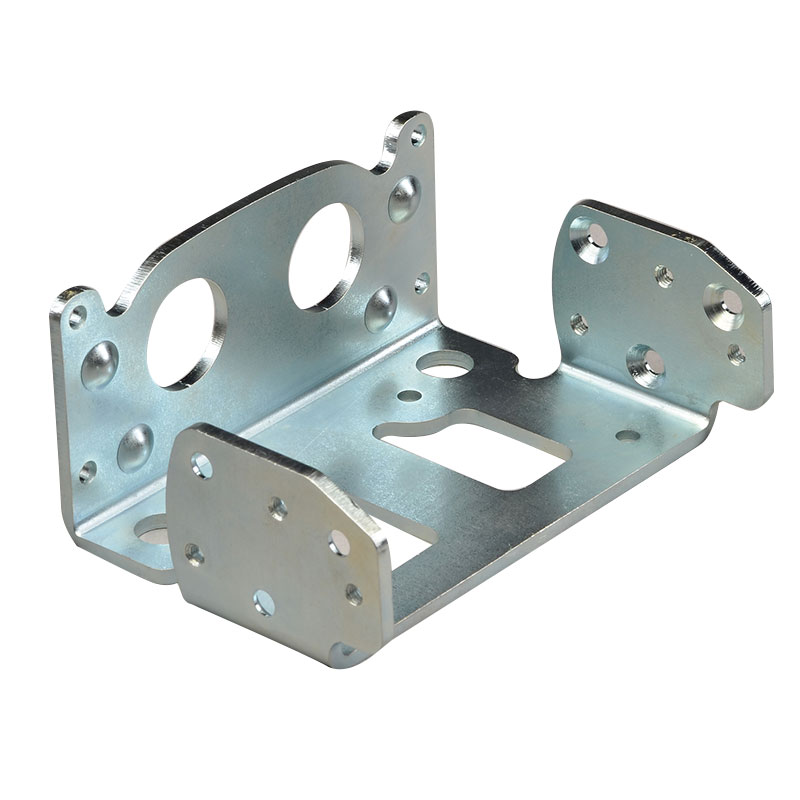

Having a sound business enterprise credit score, outstanding after-sales assistance and modern producing facilities, we have now earned an exceptional name among our shoppers across the planet for Aluminum Sheet Metal Parts Sheet Metal Fabrication,Aluminum Bending Anodized Sheet Metal Fabrication,Aluminum CNC Machining Sheet Metal Fabrication,Sheet Metal Fabrication Aluminum Enclosures, And we could help seeking for just about any goods from the customers' needs. Make sure present the best Company, the most effective High-quality, The fast Delivery.

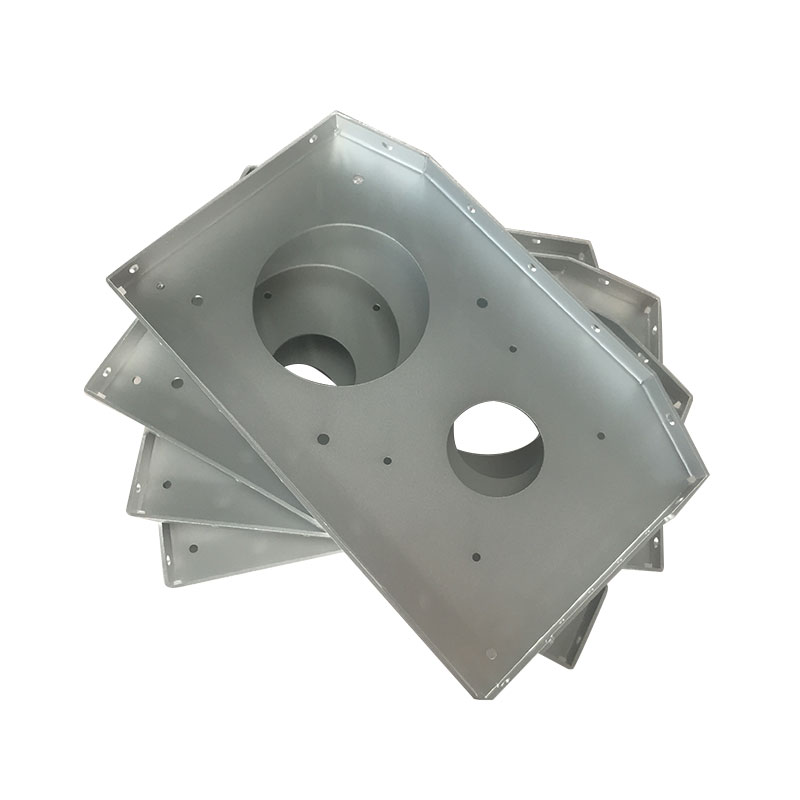

Aluminum Sheet Metal Parts Sheet Metal Fabrication, Being the top solutions of our factory, our solutions series have been tested and won us experienced authority certifications. For additional parameters and item list details, be sure to click the button to acquire additional nformation.

Hot Products

Aluminium Electronic Products Rapid Prototypes

Aluminum alloy is widely used in the industry. It is low in density, high in strength, excellent in elasticity, processability and welding characteristics. It also features good corrosion resistance, high toughness, and deformation after manufacturing.

Aluminum alloy molding can help discover potential flaws early in the product development stage, saving money in the long-run and minimizing production times. Aluminum alloy rapid prototype helps generate accurate product test data.The following is about Aluminium Electronic Products Rapid Prototypes.High Demand Aerospace Parts CNC Machining

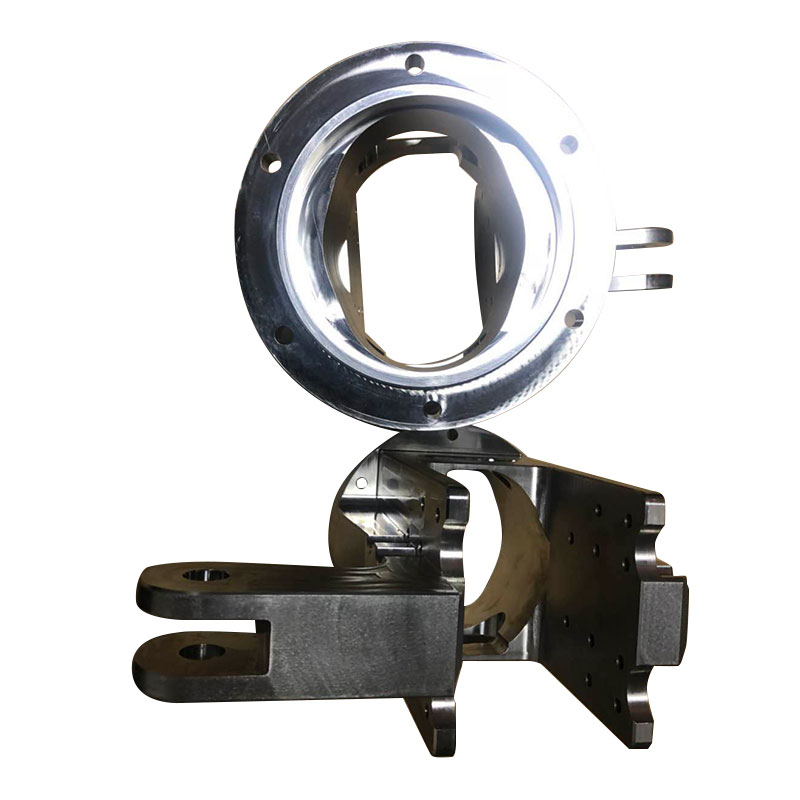

Aluminum alloy high demand aerospace parts CNC Machining has a widely application in many industries, as Aluminum is one of the most commonly used metals which is durable, lightweight, malleable, low cost, and recyclability.Plastic Electronic Products CNC Machining

The role of Plastic Electronic Products in the electronics industry has increased exponentially. The continual growth of electronic and engineering devices has led to the designing and manufacturing of various standard and custom plastic products, which can support industrial electronic applications.The following is about Plastic Electronic Products CNC Machining.E-cigarette Aluminium Tube Products CNC Turning

The following is about E-cigarette Aluminium Tube Products CNC Turning.Top Grade Medical Joint Connector CNC Turning

As one of the Top Supplier of CNC Turning service in China, Shbury has the right advanced machines and technical team to manufacture your Joint Connector economically and to your precise specifications, covering OME production for nuts, blots, screws and other Joint Connector parts.The following is about Top Grade Medical Joint Connector CNC Turning.Auto Hydraulic Valve Parts CNC Machining

For more than 10years,Shbury Tech has specialized in machining and manufacturing a wide range of hydraulic parts and components. Our state-of-the-art CNC machining capabilities allow us to provide hydraulic machining services for many industries.

Our qualified engineering team and skilled CNC machinists use advanced machining equipment to produce complex fluid control hydraulic parts at high levels of quality and precision.

We manufacture a variety of individual hydraulic components and parts such as cylinder & rods, components for motors, pumps, fittings and hose hardware. Our range of secondary services, including anodizing, heat treating, passivating, plating, and assembly, gives us the ability to provide single-source solutions that simplify our customer’s supply chain, thus reducing manufacturing costs and improving turnaround times and overall customer satisfaction. The following is about auto hydraulic valve parts CNC machining.