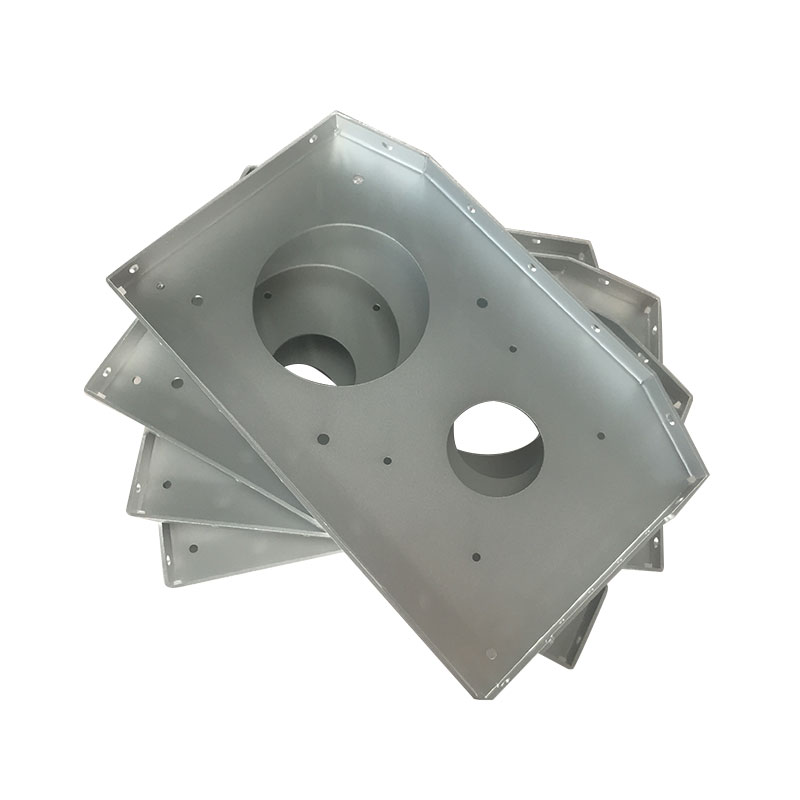

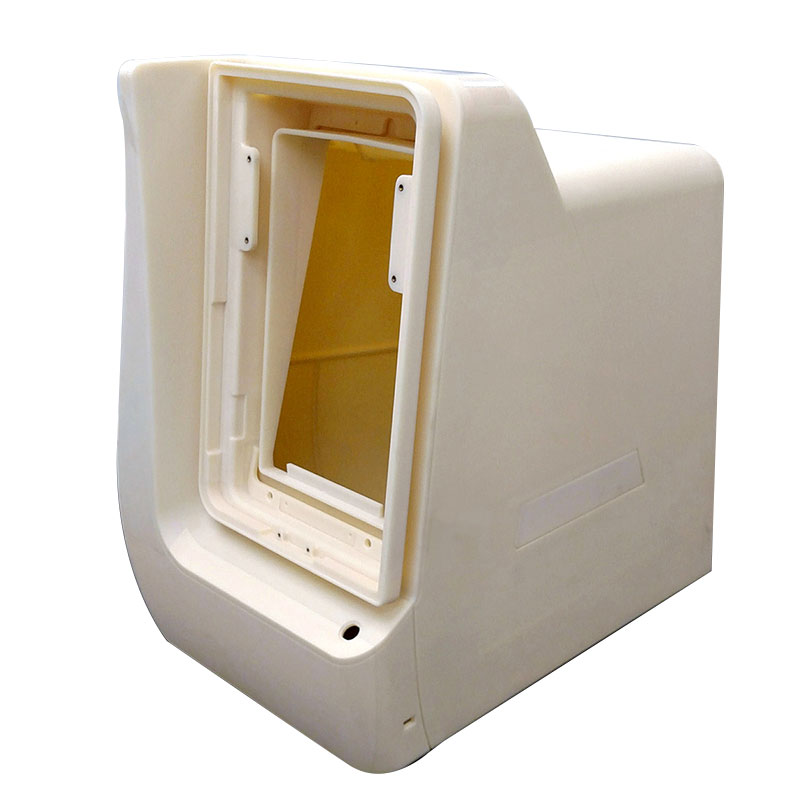

China Sheet Metal Fabrication Aluminum Enclosures Manufacturers, Suppliers, Factory

It is actually our accountability to satisfy your needs and effectively serve you. Your pleasure is our best reward. We're on the lookout forward for your stop by for joint growth for Sheet Metal Fabrication Aluminum Enclosures,Aluminum Bending Anodized Sheet Metal Fabrication,Aluminum CNC Machining Sheet Metal Fabrication,Aluminum Sheet Metal Parts Sheet Metal Fabrication, If you're on the lookout forever Excellent at a superior selling price and timely delivery. Do speak to us.

Sheet Metal Fabrication Aluminum Enclosures, Our factory insists on the principle of "Quality First, Sustainable Development", and takes "Honest Business, Mutual Benefits" as our developable goal. All members sincerely thanks for all old and new customers' support. We are going to keep working hard and offering you the highest-quality products and solutions and service.Thanks.

Hot Products

Laser Cutting Auto Parts Rapid Prototypes

Shbury offers rapid prototyping services for laser cut parts. Laser technology allows us to manufacture parts quickly and cost-effectively, allowing us to provide your team with a precision part prototype quickly and cost-effectively. Using the latest CNC technology, we can use your CAD drawings to produce a part without the delays required to design and manufacture tooling.The following is about Laser Cutting Auto Parts Rapid Prototypes.Metal Precision Mechanical Parts CNC Machining

Firstly, parts for robotic applications often have a requirement to be strong, tough and lightweight. Materials such as aluminium have ideal characteristics and can easily be machined using CNC Machining.

Similarly POM (also known as Delrin and Acetal) is commonly used for robotic mechanical cnc machining parts. Easy to machine, it is known for its low friction, high stiffness and superior dimensional stability. As a low-cost plastic, it is also a very economical option.The following is about metal precision mechanical parts CNC machining.Auto Parts Powder Coating Rapid Prototype

Powder Coating is most commonly used in the industrial sector for both (Low Volume and High Volume) Mass Production Factories such as CNC Machine Shops and Sheet Metal Fabrication Facilities. The Powder Coating material is a composite mixture of fine powderized paint pigments and fine powderized plastic particles. The fine powderized plastic particles are comprised of either (thermoplastics or thermoset plastics) such as Polyester and Epoxy. When discharged through the Powder Coat Paint Gun, the particles are ionized via an electrical coil. The positively charged ions assist the powder in the coating process as it is attracted to the negatively charged part.The following is about Auto Parts Powder Coating Rapid Prototype.High Precision Medical Device Parts CNC Machining

High Precision Medical Device Parts CNC Machining Shbury is a trusted supplier of medical device parts. Shbury is committed to improving the quality of life for patients and medical staff throughout the industry. Backed by over 10 years of CNC experience, our skilled machinists are able to create a custom medical component with the greatest accuracy possibleOffice Industry Parts Rapid Prototypes

Rapid prototyping uses 3D computer aided design (CAD) and manufacturing processes (typically additive manufacturing) to quickly develop 3D parts, models, or assemblies for research and development and/or product testing.

The use of rapid prototyping techniques allows design teams to develop multiple iterations of a design prototype without the added cost and time using traditional manufacturing and design techniques.The following is about Office Industry Parts Rapid Prototypes.Airframe Plastic Parts Vacuum Casting

Advantages of Vacuum Casting Technology Possibility of casting parts of complicated shapes, thin-wall parts or parts with negative bevels. Production of small series of prototype or final parts (from dozens up to hundreds of pieces). Favourable production costs in comparison with plastic injection moulding – the production of metal moulds is unnecessary. Fast production – a matter of days. The accuracy of production is comparable with the accuracy of parts manufactured by plastic injection moulding. A wide range of possibilities for final surface treatment.The following is about Airframe Plastic Parts Vacuum Casting.