China Auto Products Vacuum Urethane Casting Manufacturers, Suppliers, Factory

Our crew through skilled training. Skilled skilled knowledge, strong sense of company, to meet the company wants of customers for Auto Products Vacuum Urethane Casting,Auto Components Vacuum Urethane Casting, We're one from the largest 100% manufacturers in China. Several large trading corporations import goods from us, so we will supply you with the most effective price tag with all the same quality if you are interested in us.

Auto Products Vacuum Urethane Casting, We pay high attention to customer service, and cherish every customer. We have now maintained a strong reputation in the industry for many years. We're honest and work on building a long-term relationship with our customers.

Hot Products

Auto Throttle Control Shafts Parts CNC Machining

The following is about Auto Throttle Control Shafts Parts CNC Machining.Electronic Bushes Products CNC Turning

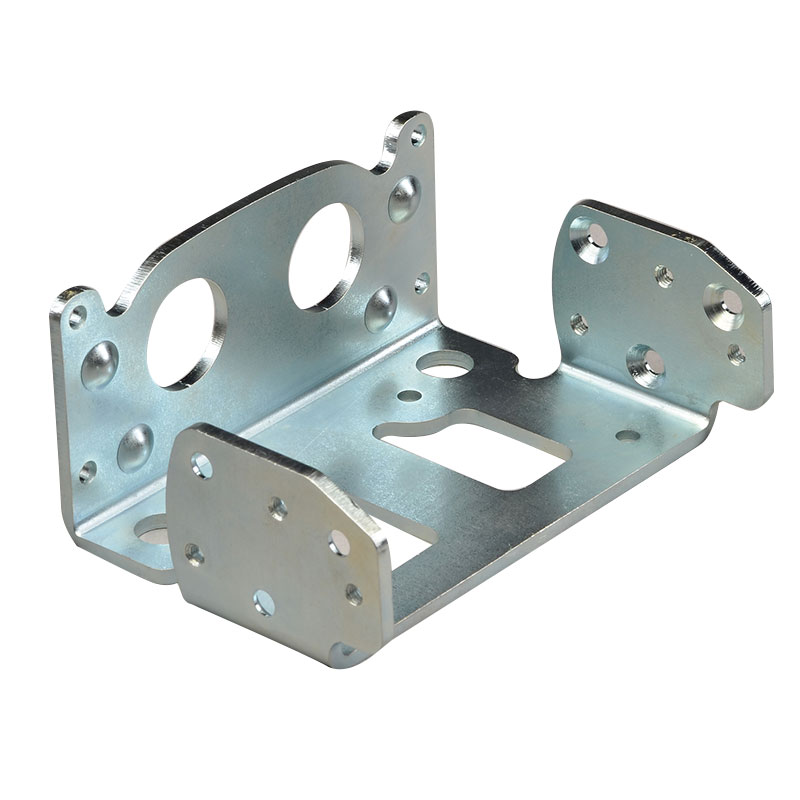

The following is about Electronic Bushes Products CNC Turning.Metal Precision Mechanical Parts CNC Machining

Firstly, parts for robotic applications often have a requirement to be strong, tough and lightweight. Materials such as aluminium have ideal characteristics and can easily be machined using CNC Machining.

Similarly POM (also known as Delrin and Acetal) is commonly used for robotic mechanical cnc machining parts. Easy to machine, it is known for its low friction, high stiffness and superior dimensional stability. As a low-cost plastic, it is also a very economical option.The following is about metal precision mechanical parts CNC machining.Steel Aerospace Parts Rapid Prototype

Rapid prototype castings are fully functioning parts with the same strength and metallurgical properties as traditionally investment cast parts. However, they carry the added advantage of substituting injected wax patterns with 3-D printed patterns, resulting in a quick and relatively low-cost alternative for those who only need a limited number of parts.

Investment casting using rapid prototypes is a reliable means to quickly produce metal castings while in the preliminary design phases of an investment casting project. This allows you to test out a sample design, which can help avoid expensive tooling changes. Oftentimes, rapid prototype castings are less costly and time-consuming than the process of machining prototypes out of bar stock or producing prototypes through weldments.The following is about Steel Aerospace Parts Rapid Prototype.Auto Oil And Gas Rubber Parts Vacuum Casting

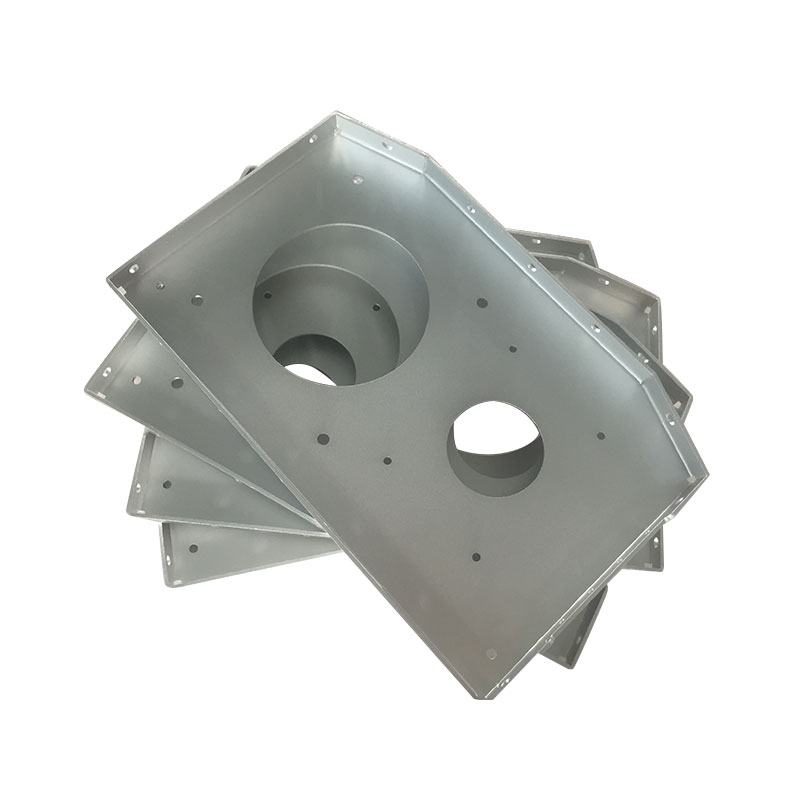

Flexible parts are often referred to colloquially as ‘rubber’ parts. Whilst rubber forms a substantial proportion of them, there are also flexible polyurethanes and thermoplastic elastomers to consider.The following is about Auto Oil And Gas Rubber Parts Vacuum Casting.Office Industry Parts Rapid Prototypes

Rapid prototyping uses 3D computer aided design (CAD) and manufacturing processes (typically additive manufacturing) to quickly develop 3D parts, models, or assemblies for research and development and/or product testing.

The use of rapid prototyping techniques allows design teams to develop multiple iterations of a design prototype without the added cost and time using traditional manufacturing and design techniques.The following is about Office Industry Parts Rapid Prototypes.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy