China Auto Transmission Products CNC Turning Manufacturers, Suppliers, Factory

We're experienced manufacturer. Wining the majority in the crucial certifications of its market for Auto Transmission Products CNC Turning,Auto Transmission Components CNC Turning, We welcome all with the shoppers and buddies to call us for mutual rewards. Hope to do further more business along with you.

Auto Transmission Products CNC Turning, Our company has already have pass the ISO standard and we're fully respect our customer 's patents and copyrights. If the customer provides their own designs, We will guarantee that they will likely be the only one can have that merchandise. We hoping that with our good products can bring our customers a great fortune.

Hot Products

Agricultural Machinery Parts CNC Machining

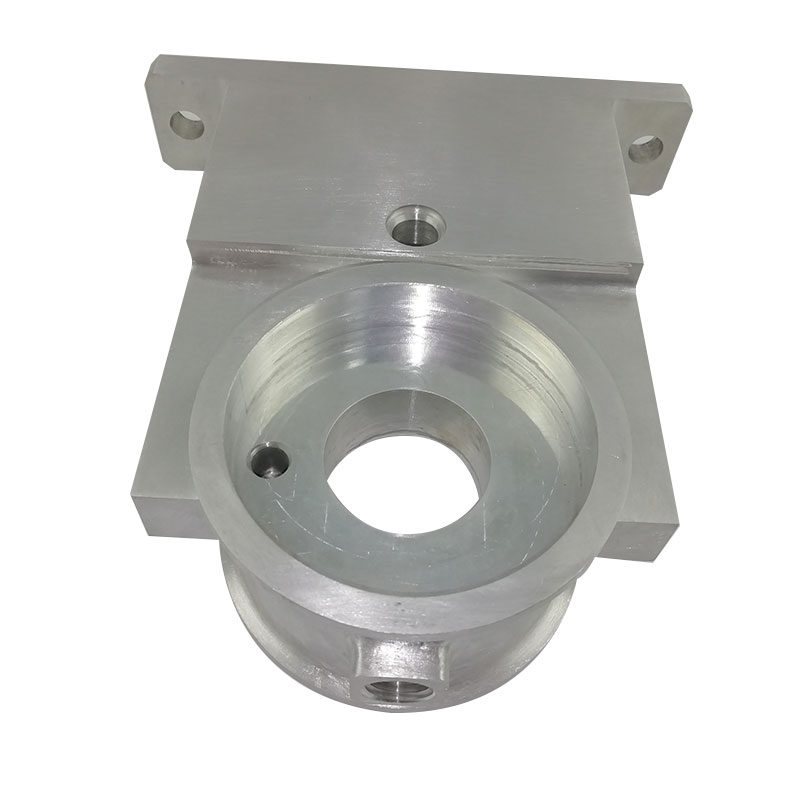

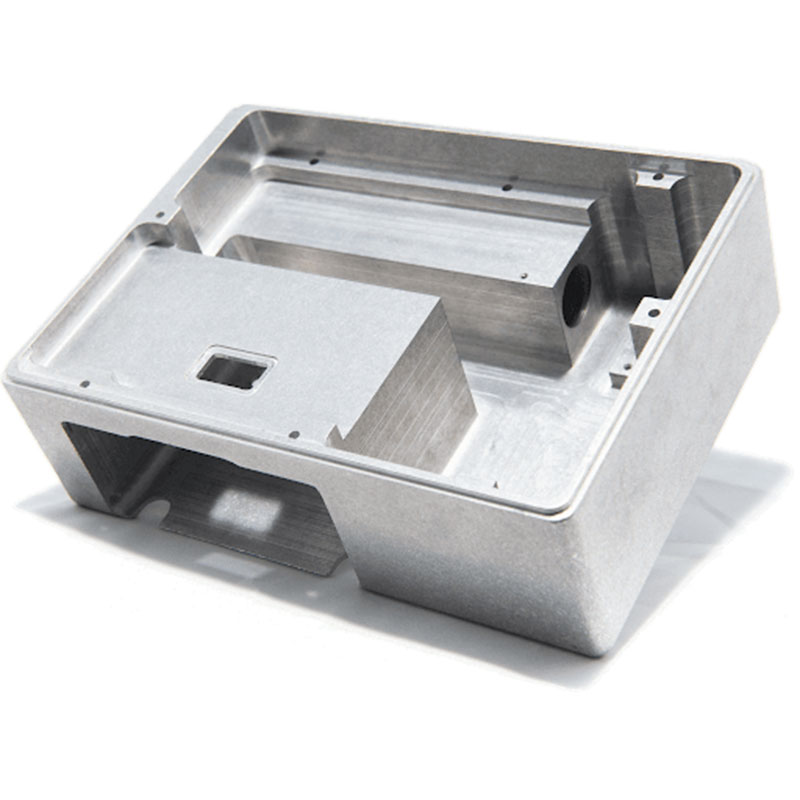

Agricultural Industry is ever evolving, one thing hasn’t changed at all: agricultural equipment component failure can have major implications for a project or a crop. Since agriculture parts are large and complex, all agriculture parts which are used on the agricultural equipment must be carefully worked with high demands of technical specifications including tight tolerance, ultra-high precision specifications, and the best durable materials to ensure the machines and equipment’ service life. So customized CNC machining services for agricultural equipment is very important in the agriculture parts manufacturing field, also custom CNC agricultural parts can make your equipment more competitive in the market.The following is about agricultural machinery parts CNC machining.Auto Transmission Parts CNC Turning

The following is about Auto Transmission Parts CNC Turning.Electronic Nozzle Products Cnc Turning

CNC aluminum tubes/pipe also known as the CNC machine nozzle, have the characteristics of corrosion resistance and lightweight, and are widely used in various industries, such as automobiles, aerospace, aviation, electronics industry, agriculture, electromechanical and so on. Aluminum pipes/tubes are ubiquitous in our life. But it’s most commonly used for shisha/hookah, tattoo or e-cigarette.The following is about Electronic Nozzle Products CNC Turning.Medical Glucose Meter Device Rapid Prototypes

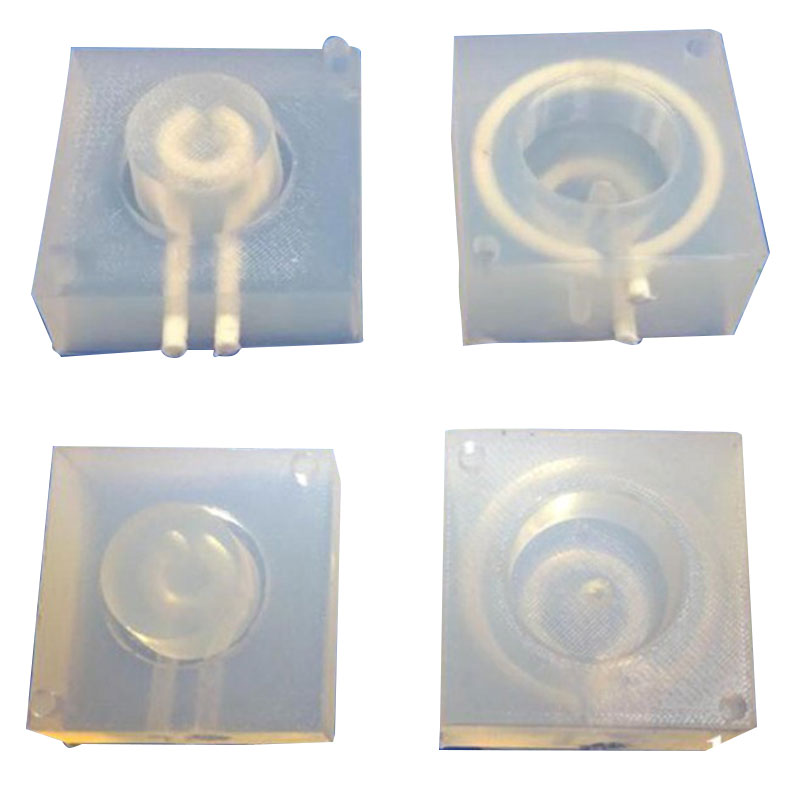

We offer a complete turnkey solution for creating master patterns and cast copies based on your CAD designs. We not only make high-quality molds but we also offer a full line of finishing services including painting, sanding, pad printing and more. We’ll help you create parts for showroom quality display models, engineering test samples, crowdfunding campaigns and more.The following is about Medical Glucose Meter Device Rapid Prototypes.Medical Device Liquid Silicone Vacuum Casting Parts

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about Medical Device Liquid Silicone Vacuum Casting Parts.Auto Waterproof Rubber Parts Vacuum Casting

We frequently vacuum cast rubber auto waterproof parts for custom seals and gaskets, but there is a wide variety of hardness’s available. Anything from the softness of a jelly baby right through to the hardness of a car tyre (Shore 30 – 95A hardness) The level of detail matches that of an injection moulded part.The following is about Auto Waterproof Rubber Parts Vacuum Casting.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy