China Brass Aerospace Products CNC Machining Manufacturers, Suppliers, Factory

We always think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and the living for Brass Aerospace Products CNC Machining,Brass Aerospace Parts CNC Milling,Brass Aerospace Components CNC Machining,OEM CNC Machining Parts for Aerospace Field,Precision CNC Milling Lathe Parts Aerospace, We look forward to providing you with our goods while in the in close proximity to long term, and you will discover our quotation is extremely realistic as well as high-quality of our solutions is incredibly outstanding!

Brass Aerospace Products CNC Machining, we sincerely hope to establish a good and long-term business relationship with your esteemed company through this opportunity, based on equality, mutual benefit and win-win business from now to the future. "Your satisfaction is our happiness".

Hot Products

Medical Device Fixture CNC Machining

The following is about Medical Device Fixture CNC Machining.Airframe Plastic Parts Vacuum Casting

Advantages of Vacuum Casting Technology Possibility of casting parts of complicated shapes, thin-wall parts or parts with negative bevels. Production of small series of prototype or final parts (from dozens up to hundreds of pieces). Favourable production costs in comparison with plastic injection moulding – the production of metal moulds is unnecessary. Fast production – a matter of days. The accuracy of production is comparable with the accuracy of parts manufactured by plastic injection moulding. A wide range of possibilities for final surface treatment.The following is about Airframe Plastic Parts Vacuum Casting.Aluminium Aerospace Parts CNC Machining

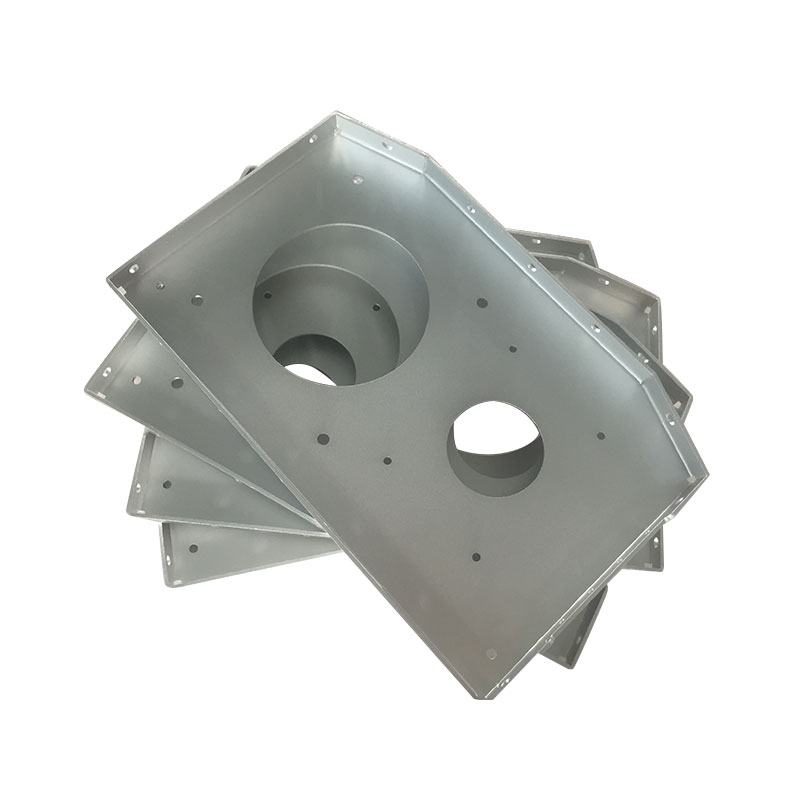

We have specialized skills and knowledge to aluminium aerospace parts CNC machining . We own advanced high-speed CNC machine tools to consistently maintain tight tolerances, produce end-use CNC machined aerospace components and aerospace prototypes to the highest precision in accordance with the requirements of our diverse customer base. Whether it is a high-volume order or a prototype project, we can always meet your exact requirements.Aluminum Sheet Metal Fabrication

Aluminum is a very common metal utilized at Shbury to manufacture various OEM products for wide-ranging applications: on-highway vehicle doors/body panels, medical equipment, medical carts, energy dispensing stations, digital display, and variable messaging controls, consumer products, kiosks, various enclosures, and countless other parts. The following is about aluminum sheet metal fabrication.Medical Device Liquid Silicone Vacuum Casting Parts

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about Medical Device Liquid Silicone Vacuum Casting Parts.Mechanical Retainer Rings CNC Turning

The following is about Mechanical Retainer Rings CNC Turning.