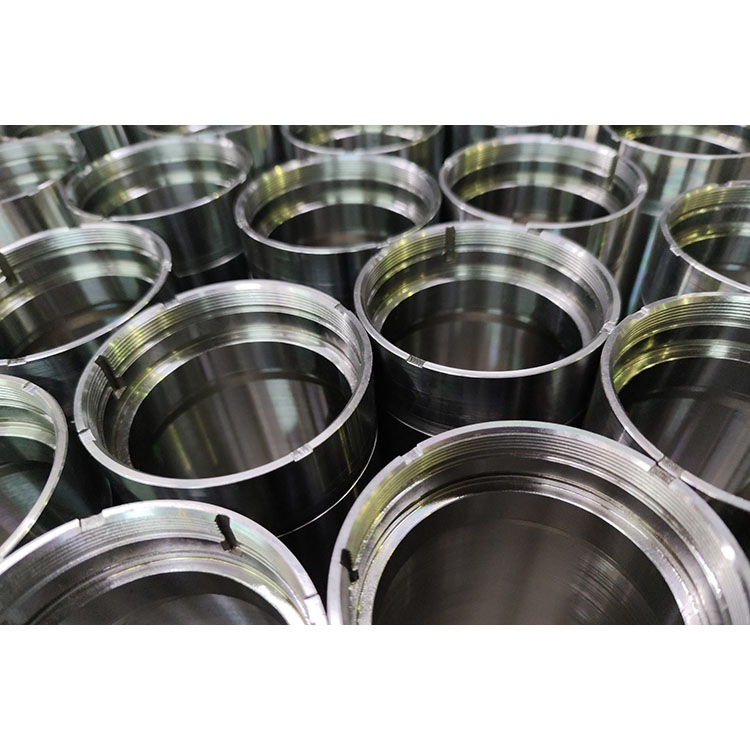

China Carbon Steel Military Products CNC Turning Manufacturers, Suppliers, Factory

Our organization puts emphasis to the administration, the introduction of talented personnel, and also the construction of team building, making an attempt hard to enhance the standard and liability consciousness of workers members. Our business successfully attained IS9001 Certification and European CE Certification of Carbon Steel Military Products CNC Turning,Carbon Steel Military Components CNC Turning, Initial enterprise, we understand each other. Additional enterprise, the trust is getting there. Our firm usually at your service anytime.

Carbon Steel Military Products CNC Turning, We hope we can establish long-term cooperation with all of the customers. And hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need to have!

Hot Products

Electronic Drive Shaft Products CNC Turning

Eccentric shaft refers to the CNC Turning Part whose axis of the outer circle and the outer circle are parallel but not coincident, generally fixed on the rotating shaft of the motor through the eccentric hole. The recess pressure on the eccentric shaft is different, which caused circumferential flow. The CNC machining eccentric hollow shaft is different from the eccentric solid shaft, the diameter of the hollow shaft is more than the solid shaft and require more space. Hollow shafts have a more polar moment of inertia, thus they can transmit more torque compared to solid shafts.The following is about Electronic Drive Shaft Products CNC Turning.Auto Throttle Control Shafts Parts CNC Machining

The following is about Auto Throttle Control Shafts Parts CNC Machining.Medical Device Fixture CNC Machining

The following is about Medical Device Fixture CNC Machining.Tight Tolerance Military Parts CNC Machining

Tight Tolerance Military Parts CNC Machining with more than 10 years in the rapid manufacturing business, Shbury has built up rich experience in CNC machining parts for both prototyping and mass production. we can achieve tight tolerances on CNC machined parts.Cold Carbon Steel Sheet Metal Parts

Cold Carbon Steel Sheet Metal PartsOffice Industry Parts Rapid Prototypes

Rapid prototyping uses 3D computer aided design (CAD) and manufacturing processes (typically additive manufacturing) to quickly develop 3D parts, models, or assemblies for research and development and/or product testing.

The use of rapid prototyping techniques allows design teams to develop multiple iterations of a design prototype without the added cost and time using traditional manufacturing and design techniques.The following is about Office Industry Parts Rapid Prototypes.