China Computer Housing Products CNC Milling Manufacturers, Suppliers, Factory

Our growth depends within the innovative equipment, fantastic talents and repeatedly strengthened technology forces for Computer Housing Products CNC Milling, Our experienced specialized workforce will probably be wholeheartedly at your provider. We sincerely welcome you to check out our web-site and organization and mail us your inquiry.

Computer Housing Products CNC Milling, Our organization. Situated inside the national civilized cities, the visitors is very easy, unique geographical and economic situations. We pursue a "people-oriented, meticulous manufacturing, brainstorm, construct brilliant" organization. hilosophy. Strict top quality management, fantastic service, reasonable cost in Myanmar is our stand on the premise of competition. If vital, welcome to make contact with us by our web page or telephone consultation, we're planning to be happy to serve you.

Hot Products

Stainless Steel Passivating Mechanical Rapid Prototypes

Stainless steel refers to steel that is resistant to weak corrosive media such as air, steam, water, and chemically etched media such as acid, alkali, salt, etc., also known as stainless acid-resistant steel. In practical applications, steel that is resistant to weak corrosive media is often referred to as stainless steel, while steel that is resistant to chemical media is referred to as acid-resistant steel. Due to the difference in chemical composition between the two, the former is not necessarily resistant to chemical media corrosion, while the latter generally has rust.The following is about Stainless Steel Passivating Mechanical Rapid Prototypes.Auto Solid Valve Housing Parts CNC Machining

Valve Housing is a key auto valve fitting to assist valve to control the flow of air or liquid through the tube. If your valve in a corrosive environment and the valve housing can't resist corrosion, it will reduce the durability.The inappropriate valve housing and valve fittings will influence valve performance as well.

So, choosing the right valve housing and valve seal material is critical to the running of an automobile valve and the whole system. The core characteristics, materials, properties of the automotive valve housing and application environment should be taken into consideration, including temperature, corrosion possibility, wear characteristics and pressure.The following is about auto solid valve housing parts CNC machining.Auto Pipe Joint Parts CNC Machining

One of the top CNC machining service suppliers in Shbury Tech, has been specialized in producing custom CNC turning pipe joints (expansion, welding, clamp) for automobile industry for over 10 years with superior quality and OEM service. Our products of CNC turned and machined pipe joint include zinc, iron, aluminum pipe joint, metal pipe joint, steel, stainless steel, brass pipe joint and other types of CNC lathe machine pipe joint. Reliable auto pipe joints are supplied to consumers with high-precision and stable quality and competitive prices.The following is about auto pipe joint parts CNC machining.3D Printing Electronic Products Rapid Prototypes

Consumers have come to expect periodic releases of ever-more advanced electronics. From smartphones to smart home systems and wearables, new consumer products require significant evaluation and testing before they hit the market. Before moving to mass manufacturing, these new products require rigorous testing for quality, functionality, and user experience.

With new consumer product upgrade and release cycles becoming tighter, electronics designers need a solution that helps reduce the time involved in each R&D and prototyping cycle. By far, the most time-consuming and least productive portion of R&D is repetitive design, build, and test cycles.

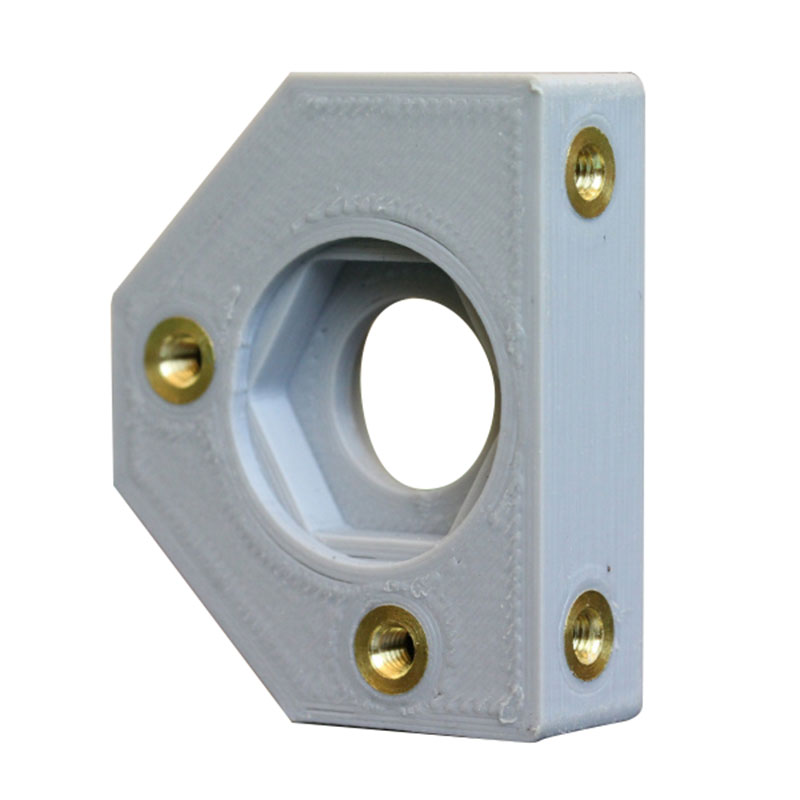

Rapid prototyping with traditional manufacturing processes is anything but fast, so designers need a real solution for true rapid prototyping. This illustrates the value of 3D printing in consumer electronics development and prototyping; designers can quickly create fully-functional electronics in a matter of hours rather than days, and this can be done in-house. Designers can innovate more often, quickly test functionality, and implement redesigns before manufacturing at scale. The following is about 3D Printing Electronic Products Rapid Prototypes.Brass Inserts Plastic Electronic Products Vacuum Casting

Shbury has a fully equipped Vacuum Casting suite with multiple vacuum casting machines. We also have 3D printing facilities which are used for producing the master pattern. For best quality, we use high definition SLA models.The following is about Brass Inserts Plastic Electronic Products Vacuum Casting.Auto Flanges Fuser Rollers Parts CNC Turning

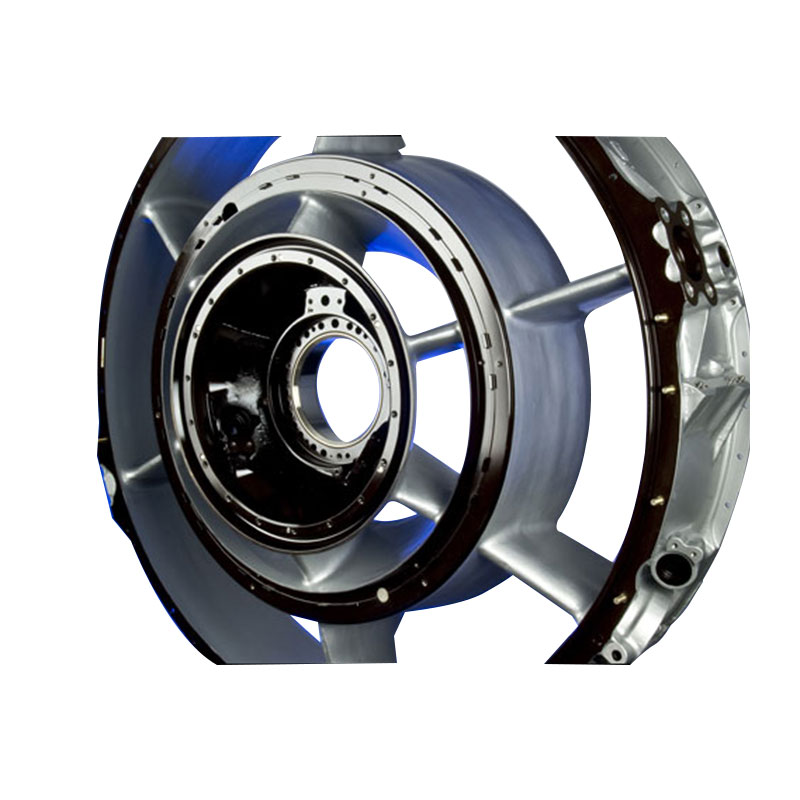

With the aid of our diligent professionals, we are engaged in manufacturing and supplying Turning Flange. These flanges are available for the clients in different sizes and specification. Precision turned from raw metal using high-end cnc machines, these flanges are provided to a large number of customers ranging from engineering to automotive industries Our offered flanges are quality tested with the aid of diligent analysts before the final dispatch. The Turning Flange is provided at the specified place on time.The following is about Auto Flanges Fuser Rollers Parts CNC Turning.