China Galvanized Sheet Bending Parts Manufacturers, Suppliers, Factory

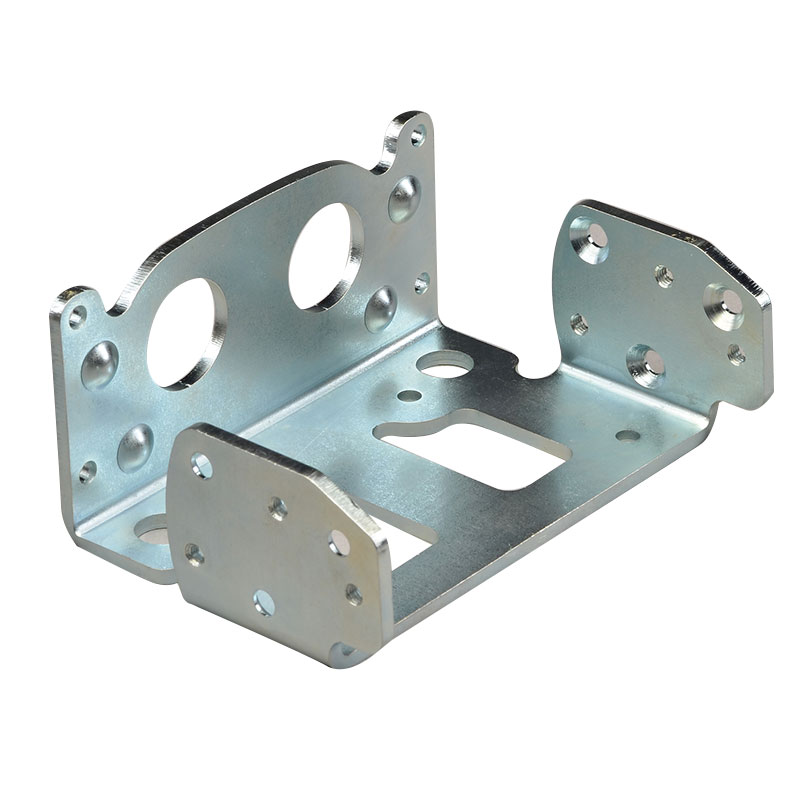

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for Galvanized Sheet Bending Parts,Galvanized Metal Bending Parts and Galvanized Sheet Metal,Metal Sheet Forming Steel Bending Parts Bending Steel Plate,Galvanized Sheet Bending Equipment Metal Parts Sheet Metal,CNC Bending Galvanized Sheet Metal Fabrication Parts, In a word, when you choose us, you choose a ideal existence. Welcome to visit our factory and welcome your get! For even further inquiries, remember to usually do not hesitate to make contact with us.

Galvanized Sheet Bending Parts, We adopt advanced production equipment and technology, and perfect testing equipment and methods to ensure our product quality. With our high-level talents, scientific management, excellent teams, and attentive service, our products are favored by domestic and foreign customers. With your support, we will build a better tomorrow!

Hot Products

Dental Instruments Parts CNC Machining

The following is about Dental Instruments Parts CNC Machining.Carbon Steel Military Parts CNC Turning

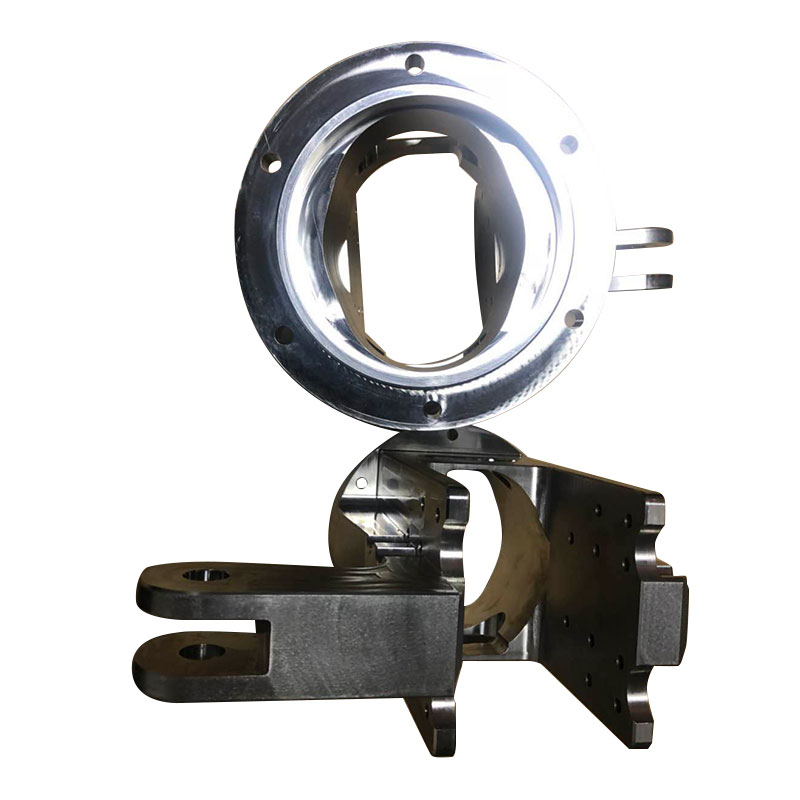

Shbury specializes in precision CNC parts and components that match military standards. We can provide complex machined parts at close tolerances along with accurate supporting documentation. The following is about Carbon Steel Military Parts CNC Turning.Auto Solid Valve Housing Parts CNC Machining

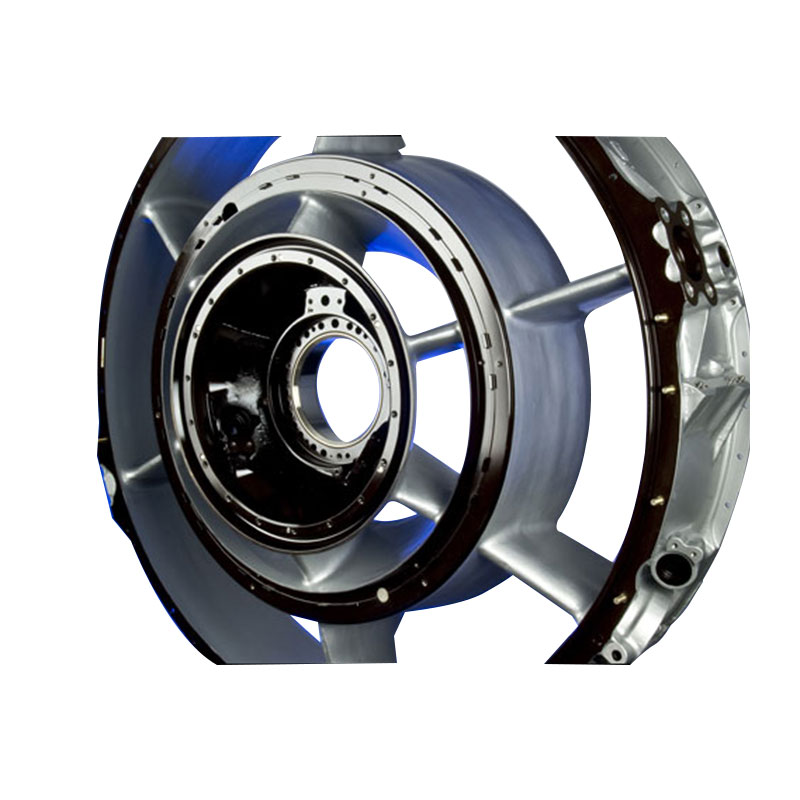

Valve Housing is a key auto valve fitting to assist valve to control the flow of air or liquid through the tube. If your valve in a corrosive environment and the valve housing can't resist corrosion, it will reduce the durability.The inappropriate valve housing and valve fittings will influence valve performance as well.

So, choosing the right valve housing and valve seal material is critical to the running of an automobile valve and the whole system. The core characteristics, materials, properties of the automotive valve housing and application environment should be taken into consideration, including temperature, corrosion possibility, wear characteristics and pressure.The following is about auto solid valve housing parts CNC machining.Auto Parts Vacuum Urethane Casting

Vacuum casting technology offers a wide variety of materials to facilitate the creation of cast urethane parts, typically for functional test, pre-production evaluation and low volume production. Cast auto urethane parts are quick and inexpensive without the need to invest any metal tooling when quantities are only dozens of short runs, and can be delivered within weeks in most instances. The following is about Auto Parts Vacuum Urethane Casting.Electronic Hookah Nozzle Products CNC Turning

The following is about Electronic Hookah Nozzle Products CNC Turning.Auto Throttle Control Shafts Parts CNC Machining

The following is about Auto Throttle Control Shafts Parts CNC Machining.