China CNC Bending Galvanized Sheet Metal Fabrication Parts Manufacturers, Suppliers, Factory

To create much more benefit for shoppers is our enterprise philosophy; client growing is our working chase for CNC Bending Galvanized Sheet Metal Fabrication Parts,Galvanized Sheet Bending Parts,Galvanized Metal Bending Parts and Galvanized Sheet Metal,Metal Sheet Forming Steel Bending Parts Bending Steel Plate,Galvanized Sheet Bending Equipment Metal Parts Sheet Metal, We sincerely welcome mates from all over the globe to cooperate with us to the basis of long-term mutual added benefits.

CNC Bending Galvanized Sheet Metal Fabrication Parts, We'll supply much better products and solutions with diversified designs and expert services. At the same time, welcome OEM, ODM orders, invite friends at home and abroad together common development and achieve win-win, integrity innovation, and expand business opportunities! If you have any question or need more information be sure to feel free to contact us. We are looking forward to receiving your enquiries soon.

Hot Products

Auto Parts Powder Coating Rapid Prototype

Powder Coating is most commonly used in the industrial sector for both (Low Volume and High Volume) Mass Production Factories such as CNC Machine Shops and Sheet Metal Fabrication Facilities. The Powder Coating material is a composite mixture of fine powderized paint pigments and fine powderized plastic particles. The fine powderized plastic particles are comprised of either (thermoplastics or thermoset plastics) such as Polyester and Epoxy. When discharged through the Powder Coat Paint Gun, the particles are ionized via an electrical coil. The positively charged ions assist the powder in the coating process as it is attracted to the negatively charged part.The following is about Auto Parts Powder Coating Rapid Prototype.Stainless Steel Passivating Mechanical Rapid Prototypes

Stainless steel refers to steel that is resistant to weak corrosive media such as air, steam, water, and chemically etched media such as acid, alkali, salt, etc., also known as stainless acid-resistant steel. In practical applications, steel that is resistant to weak corrosive media is often referred to as stainless steel, while steel that is resistant to chemical media is referred to as acid-resistant steel. Due to the difference in chemical composition between the two, the former is not necessarily resistant to chemical media corrosion, while the latter generally has rust.The following is about Stainless Steel Passivating Mechanical Rapid Prototypes.Motorcycles Parts CNC Machining

CNC machines are indispensable for motorcycles simply for the fact that you can create bike parts. People should know that these machines easily create bike parts, which are easily damaged during accidents making them easier to replace. Oftentimes during light crashes, bike parts can be damaged, scratched, crushed, or even brushed against the pavement and in need of replacements.

If you have a damaged bike part and need of a replacement, a CNC Machining motorcycles spare parts would be the desired way to go about it.The following is about motorcycles parts CNC machining.Electronic Hookah Nozzle Products CNC Turning

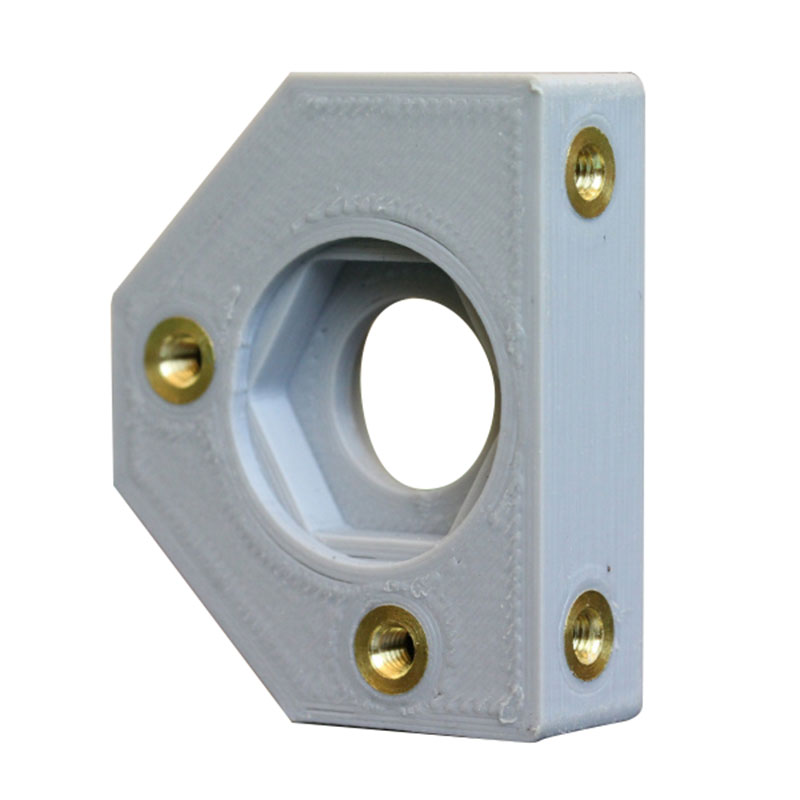

The following is about Electronic Hookah Nozzle Products CNC Turning.Metal Precision Mechanical Parts CNC Machining

Firstly, parts for robotic applications often have a requirement to be strong, tough and lightweight. Materials such as aluminium have ideal characteristics and can easily be machined using CNC Machining.

Similarly POM (also known as Delrin and Acetal) is commonly used for robotic mechanical cnc machining parts. Easy to machine, it is known for its low friction, high stiffness and superior dimensional stability. As a low-cost plastic, it is also a very economical option.The following is about metal precision mechanical parts CNC machining.Aircraft Seat Frame Parts Rapid Prototypes

Innovative prototypes from aerospace engineering workshops are already in flight today. Rapid prototyping is already being used to produce specific aircraft interior components such as air ducts, armrests, seat frames end caps, seat framework and wall panels. Prototyping will be an integral piece of the manufacturing and new part development processes for years to come. The prototypes from aerospace engineering will without a doubt be at the center of space exploration as well as the coming transportation revolution.The following is about Aircraft Seat Frame Parts Rapid Prototypes.