China Metal Precision Mechanical Components CNC Machining Manufacturers, Suppliers, Factory

We often stick to the basic principle "Quality 1st, Prestige Supreme". We are fully committed to giving our shoppers with competitively priced excellent products and solutions, prompt delivery and skilled provider for Metal Precision Mechanical Components CNC Machining,Metal Precision Mechanical Parts CNC Milling,Metal Precision Mechanical Products CNC Machining, To significantly improve our assistance quality, our company imports a large number of international advanced devices. Welcome clients from your home and abroad to simply call and inquire!

Metal Precision Mechanical Components CNC Machining, As an experienced group we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of our company is to build up a satisfactory memory to all customers, and establish a long term win-win business relationship. Choose us, we always wait for your appearance!

Hot Products

Brass Aerospace Parts CNC Machining

Brass Aerospace Parts CNC Machining have several key advantages compared to machining other materials. Brass turned and machined parts and components are durable, cost-efficient, and even create a tighter seal for fittings. In addition, brass machining and turning parts have a high heat and corrosion resistance! More importantly, Shbury’s brass machined parts are easy to machine and join, and made to your specifications and standards!Aluminium Anodizing Military Parts CNC Turning

The Aluminium Anodizing Military Parts CNC Turning provided by Shbury are made of 6061 aluminum using CNC milling, turning and drilling machines for a variety of equipment. Our precision machining services have the ability to upgrade your current design to solid piece with the exact specification, also ensure consistent quality and short lead time for your custom prototype and low/high volume production parts. Black anodizing process is applied on the Aluminium Anodizing Military Parts CNC Turning, which increases the thickness of the natural oxide layer on the surface of aluminum components, and improves its corrosion and wear resistance. Our aluminum anodizing services provide an anodized aluminum coating that meets industry standards. Other colors can be dyed during the process. More surface treatment services available to give your aluminum drilling parts or milling parts a smooth surface finish.Indirectly Human Medical Device Parts CNC Machining

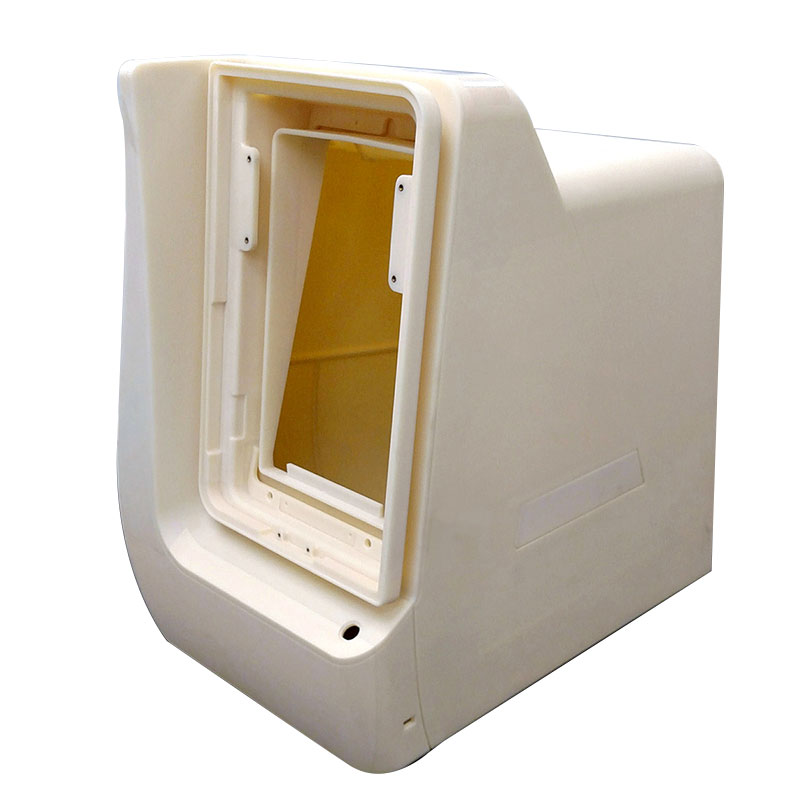

The following is about Indirectly Human Medical Device Parts CNC Machining.Medical Device Fixture CNC Machining

The following is about Medical Device Fixture CNC Machining.Auto Flanges Fuser Rollers Parts CNC Turning

With the aid of our diligent professionals, we are engaged in manufacturing and supplying Turning Flange. These flanges are available for the clients in different sizes and specification. Precision turned from raw metal using high-end cnc machines, these flanges are provided to a large number of customers ranging from engineering to automotive industries Our offered flanges are quality tested with the aid of diligent analysts before the final dispatch. The Turning Flange is provided at the specified place on time.The following is about Auto Flanges Fuser Rollers Parts CNC Turning.Auto Parts Heat Treatment Rapid Prototypes

Heat treatments can be applied to metal alloys throughout the manufacturing process. For CNC machined parts, heat treatments are typically applied either:

Before CNC machining: When a standardized grade of a metal alloy is requested that is readily available, the CNC service provider will machine the parts directly from that stock material. This is often the best option for reducing lead times.

After CNC machining: Some heat treatments significantly increase the hardness of the material or are used as a finishing step after forming. In these cases, the heat treatment is applied after CNC machining, as high hardness reduces the machinability of a material. For example, this is standard practice when CNC machining tool steel parts.The following is about Auto Parts Heat Treatment Rapid Prototypes.