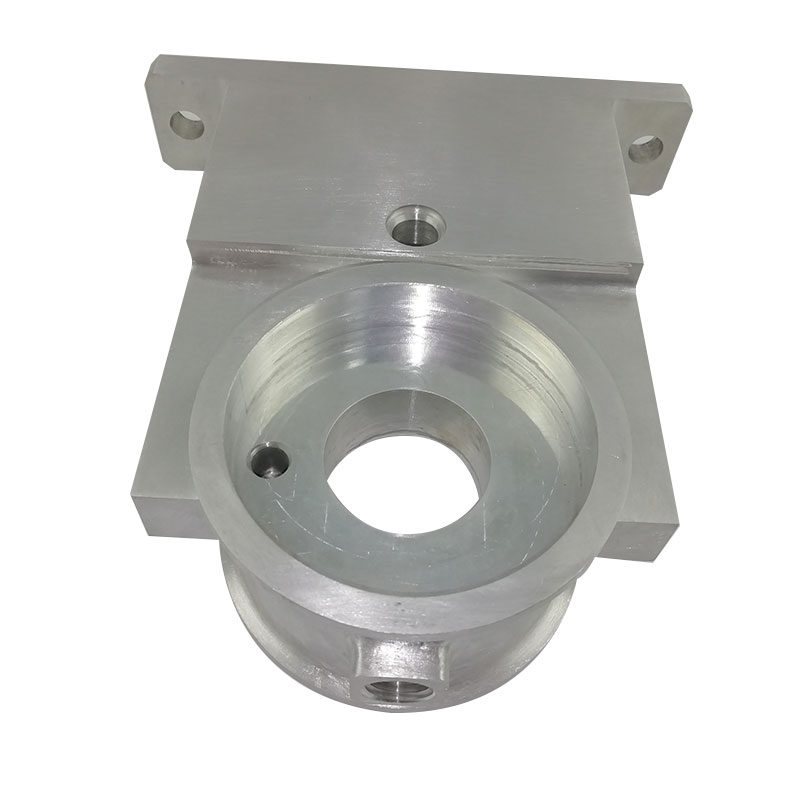

China Tight Tolerance Military Parts CNC Milling Manufacturers, Suppliers, Factory

Our company promises all users of the first-class products and the most satisfying post-sale service. We warmly welcome our regular and new customers to join us for Tight Tolerance Military Parts CNC Milling,Tight Tolerance Military Products CNC Machining,Tight Tolerance Military Components CNC Machining, we could solve our customer problems asap and do the profit for our customer. For those who need excellent company and top quality , pls choose us , thanks !

Tight Tolerance Military Parts CNC Milling, Our mission is "Provide Merchandise with Reliable Quality and Reasonable Prices". We welcome customers from every corner of the world to contact us for future business relationships and achieving mutual success!

Hot Products

Mechanical Retainer Rings CNC Turning

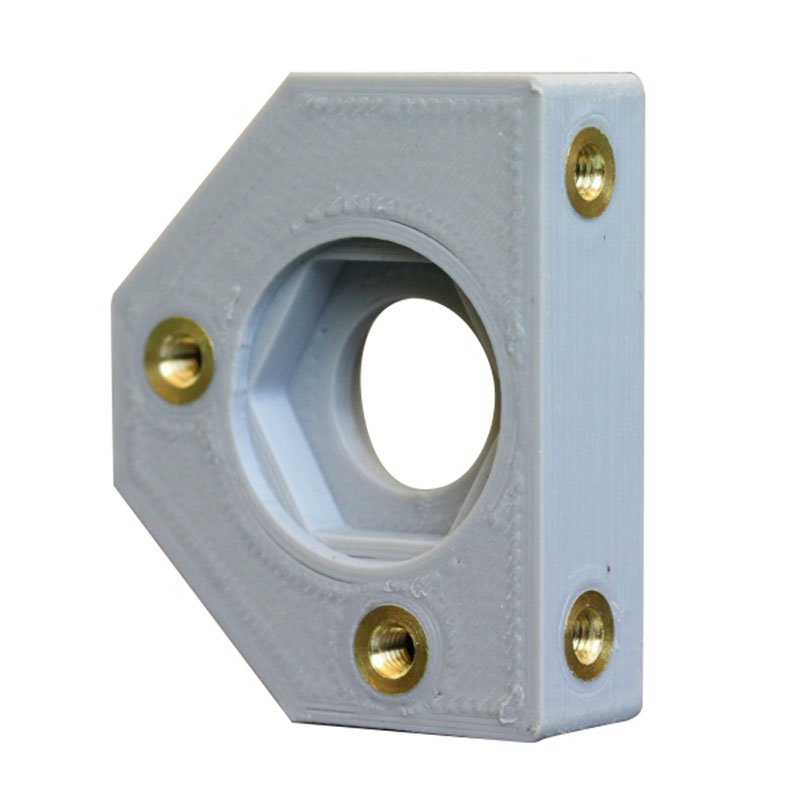

The following is about Mechanical Retainer Rings CNC Turning.OEM Precision CNC Machining aluminium Anodizing Spare Parts

OEM Precision CNC Machining aluminium Anodizing Spare Parts:Before we look into aluminum parts anodizing, we should understand the exact meaning and purpose of anodizing. Generally, anodizing is a process through which a layer of metal oxide is electrolytically embedded onto the surface of the pure metal, in this case, Aluminum pars anodizing is like painting but when anodizing, the oxide layer is fully integrated into the underlying metal. Because of this, it can hardly chip or peel. Anodizing is the result of a highly controlled oxidation process that converts the surface of the metal into a corrosion-resistant, durable cover.Agricultural Machinery Parts CNC Machining

Agricultural Industry is ever evolving, one thing hasn’t changed at all: agricultural equipment component failure can have major implications for a project or a crop. Since agriculture parts are large and complex, all agriculture parts which are used on the agricultural equipment must be carefully worked with high demands of technical specifications including tight tolerance, ultra-high precision specifications, and the best durable materials to ensure the machines and equipment’ service life. So customized CNC machining services for agricultural equipment is very important in the agriculture parts manufacturing field, also custom CNC agricultural parts can make your equipment more competitive in the market.The following is about agricultural machinery parts CNC machining.Laser Cutting Auto Parts Rapid Prototypes

Shbury offers rapid prototyping services for laser cut parts. Laser technology allows us to manufacture parts quickly and cost-effectively, allowing us to provide your team with a precision part prototype quickly and cost-effectively. Using the latest CNC technology, we can use your CAD drawings to produce a part without the delays required to design and manufacture tooling.The following is about Laser Cutting Auto Parts Rapid Prototypes.Accurate Mechanical Parts CNC Machining

The following is about accurate mechanical parts CNC machining.Polishing Cast Bronze Brass Copper Casting

China Polishing Cast Bronze Brass Copper Casting Factory Directly Supply. Guoye Optoelectronics is Polishing Cast Bronze Brass Copper Casting manufacturer and supplier in China.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy