China Tight Tolerance Military Products CNC Machining Manufacturers, Suppliers, Factory

We've been committed to offering easy,time-saving and money-saving one-stop purchasing service of consumer for Tight Tolerance Military Products CNC Machining,Tight Tolerance Military Parts CNC Milling,Tight Tolerance Military Components CNC Machining, Adhering on the company principle of mutual gains, we have won superior popularity amid our shoppers because of our excellent products and services, excellent products and aggressive selling prices. We warmly welcome shoppers from home and overseas to cooperate with us for common achievements.

Tight Tolerance Military Products CNC Machining, If any item be of curiosity to you, make sure you allow us to know. We will try our best to satisfy your requirements with high quality products and solutions, the best prices and prompt delivery. Be sure to feel free to contact us at any time. We'll reply you when we receive your inquiries. You should note that samples are available before we start our business.

Hot Products

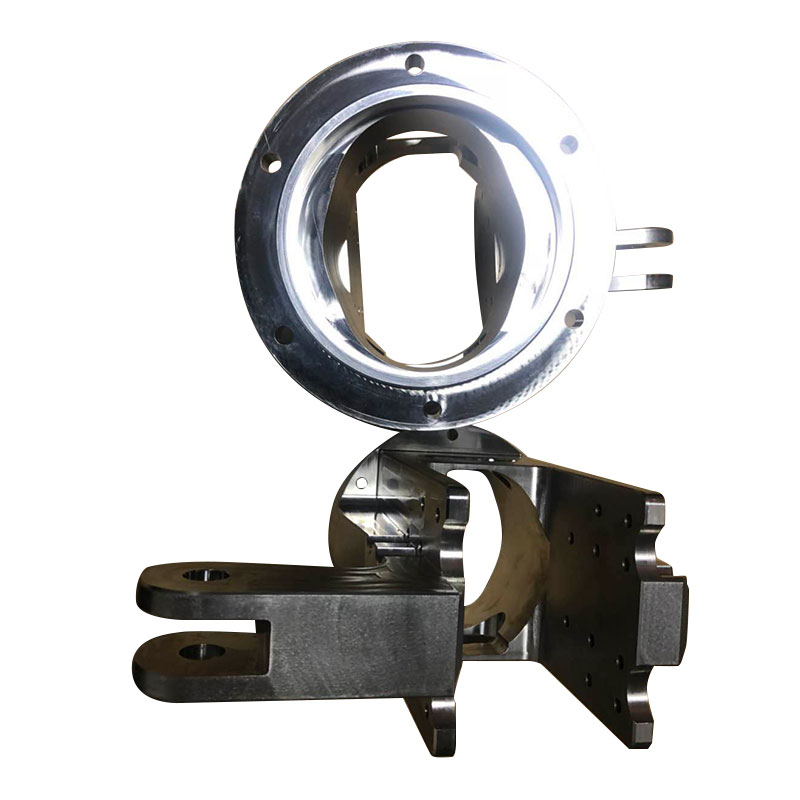

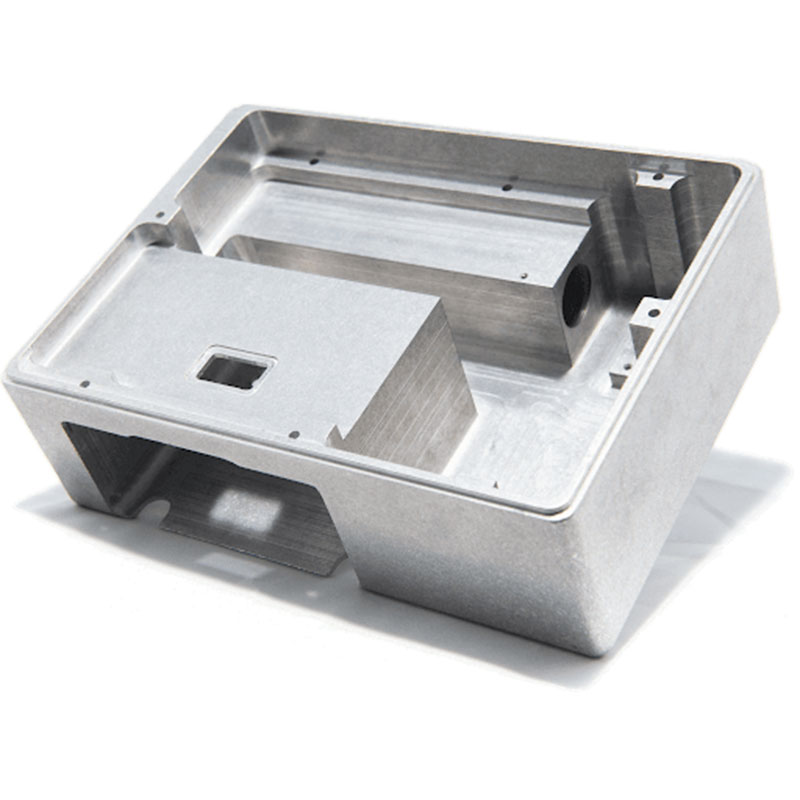

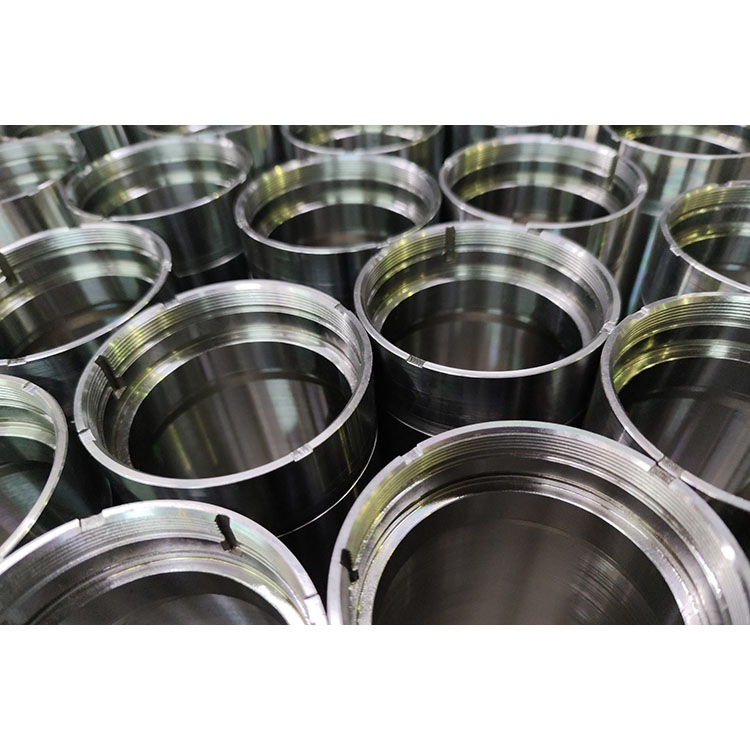

Highest Level Military Parts Cnc Machining

CNC machining service provides a significant manufacturing solution for CNC military parts of a diversity of military and defense equipment, like army equipment, navy equipment, military aircraft, military vehicles, ordnance, ship & submarines, air force equipment, marine corps equipment, coast guard equipment, weapons, etc. To meet the high demands and high standard of military instruments, online Highest Level Military Parts CNC Machining CNC machining , advanced processing technique and sophisticated devices to ensure the high efficiency, high precision, tight tolerance, long service life and outstanding performance of the products.Flexible Silicone Electronic Products Vacuum Casting

Urethane Casting - Silicone Molding Vacuum casting (also known as urethane casting or silicone moulding) is a manufacturing method that uses silicone moulds to produce plastic parts in a relatively simple way and without the high costs and high lead times required for steel or aluminium moulds.The following is about flexible silicone electronic products vacuum casting.Cold Carbon Steel Sheet Metal Parts

Cold Carbon Steel Sheet Metal PartsSilicone Buttons Products Vacuum Casting

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal. But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about silicone buttons products vacuum casting.Titanium Aerospace Parts CNC Machining

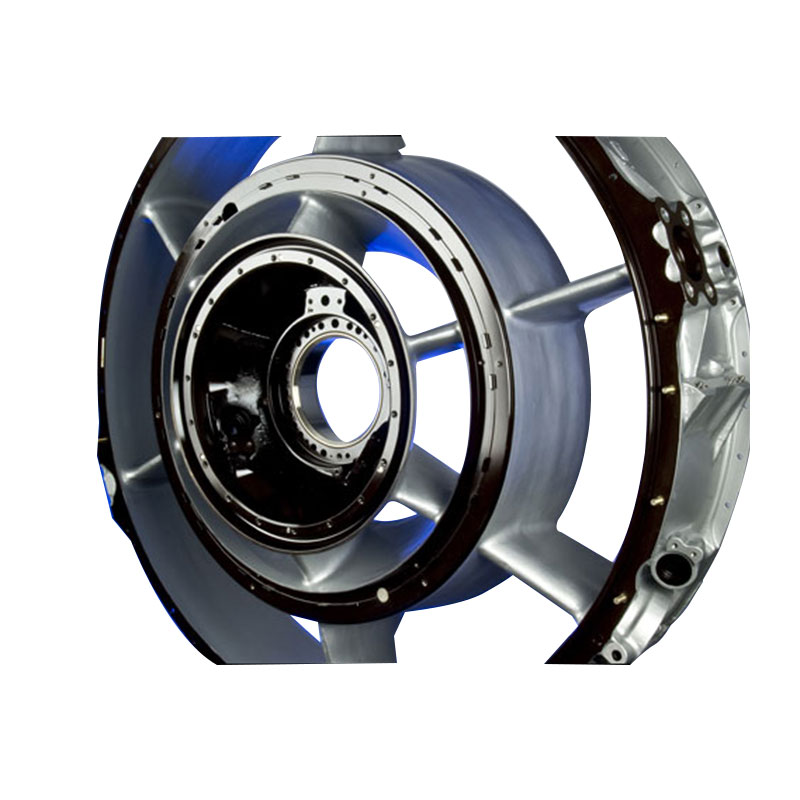

Our high volume components can withstand the intense pressures and various challenges of the Aerospace industry. Common components that we machine for the Aerospace industry include shafts, turbine disks, impellers, and more.The following is about titanium aerospace parts CNC machining.Robotic Mechanical Parts CNC Machining

Firstly, parts for robotic applications often have a requirement to be strong, tough and lightweight. Materials such as aluminium have ideal characteristics and can easily be machined using CNC Machining.

Similarly POM (also known as Delrin and Acetal) is commonly used for robotic mechanical cnc machining parts. Easy to machine, it is known for its low friction, high stiffness and superior dimensional stability. As a low-cost plastic, it is also a very economical option.The following is about robotic mechanical parts CNC machining.