Products

- View as

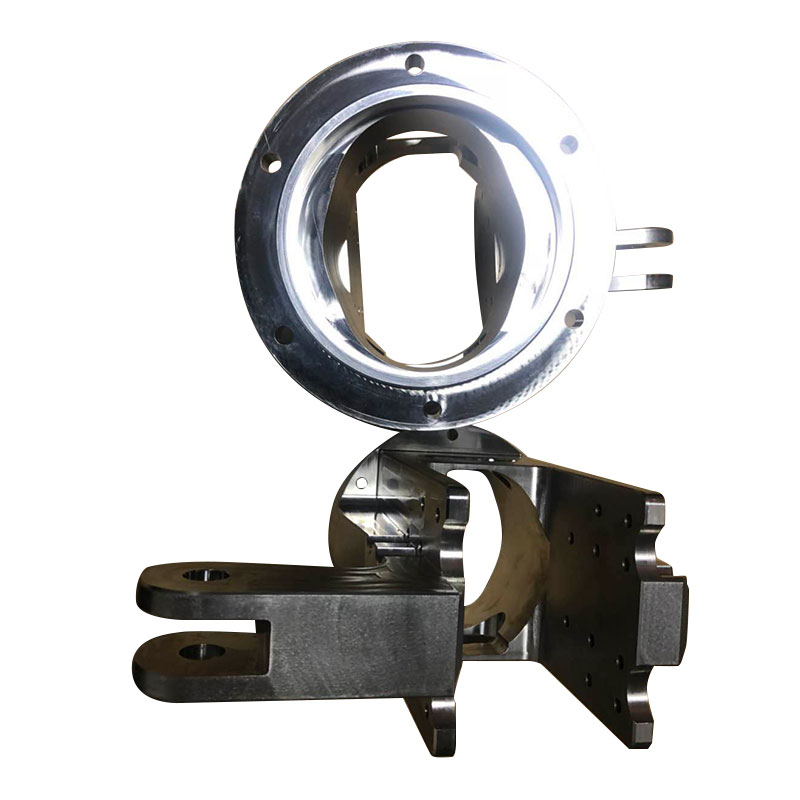

Airframe Plastic Parts Vacuum Casting

Advantages of Vacuum Casting Technology Possibility of casting parts of complicated shapes, thin-wall parts or parts with negative bevels. Production of small series of prototype or final parts (from dozens up to hundreds of pieces). Favourable production costs in comparison with plastic injection moulding – the production of metal moulds is unnecessary. Fast production – a matter of days. The accuracy of production is comparable with the accuracy of parts manufactured by plastic injection moulding. A wide range of possibilities for final surface treatment.The following is about Airframe Plastic Parts Vacuum Casting.

Read MoreSend InquiryAerospace Seal Parts Vacuum Casting

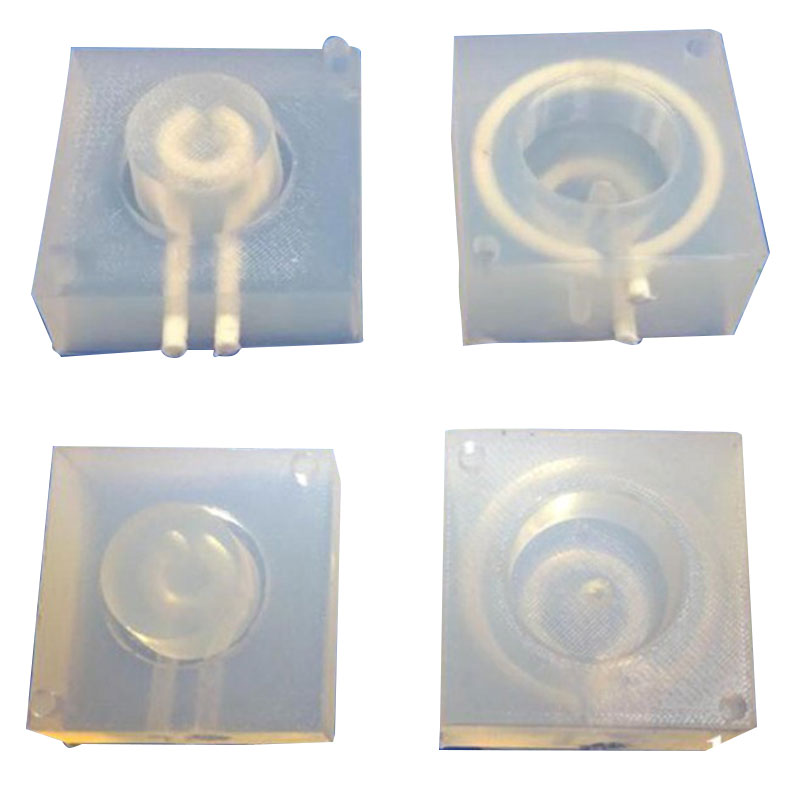

Silicone is cheaper in terms of cost compared to the injection mold. The reason for this difference in cost, is the nature of injection mold, being built on steel or aluminum parts. The cost if silicone mold can be from hundreds to thousands while the injection one will range from thousands to tens of thousands.The following is about Aerospace Seal Parts Vacuum Casting.

Read MoreSend InquiryAerospace Gasket Parts Vacuum Casting

Vacuum Casting may be used with a multitude of materials. This method of casting is typically made polyurethane prototype parts in a timely manner. A wide variety of textures, rigidity, strength, hardness or softness may be produced with this manufacturing technique. The parts are usually made with polyurethane resins because it can emulate the texture of other materials. The molds are typically made out of silicone and may even be produced with a 3D printer.The following is about Aerospace Gasket Parts Vacuum Casting.

Read MoreSend InquiryAuto Waterproof Rubber Parts Vacuum Casting

We frequently vacuum cast rubber auto waterproof parts for custom seals and gaskets, but there is a wide variety of hardness’s available. Anything from the softness of a jelly baby right through to the hardness of a car tyre (Shore 30 – 95A hardness) The level of detail matches that of an injection moulded part.The following is about Auto Waterproof Rubber Parts Vacuum Casting.

Read MoreSend InquiryAuto O Right Silicone Parts Vacuum Casting

The original model for vacuum casting is generally created using the stereolithography method. From this model, a primary mold of silicone is created and filled in the vacuum chamber with liquid polyurethane casting resin (PUR). The vacuum prevents bubbles and shrink holes even in complex molded parts. After hardening, the service of the casting is finished. Given the numerous available polyurethanes and ureols (PU hard foam), many conventional production plastics (injection molding) can be simulated.The following is about Auto O Right Silicone Parts Vacuum Casting.

Read MoreSend InquiryAuto Oil And Gas Rubber Parts Vacuum Casting

Flexible parts are often referred to colloquially as ‘rubber’ parts. Whilst rubber forms a substantial proportion of them, there are also flexible polyurethanes and thermoplastic elastomers to consider.The following is about Auto Oil And Gas Rubber Parts Vacuum Casting.

Read MoreSend Inquiry