China Auto Sensor Housing Products CNC Machining Manufacturers, Suppliers, Factory

So as to give you ease and enlarge our company, we also have inspectors in QC Team and assure you our greatest support and product or service for Auto Sensor Housing Products CNC Machining,Auto Sensor Housing Parts CNC Milling,Auto Sensor Housing Components CNC Machining,Precision CNC Machining Parts, Aluminum Housing,Plastic Parts Mechanical Housing CNC Machining, The principle of our company is to provide high-quality products, professional service, and honest communication. Welcome all friends to place trial order for creating a long-term business relationship.

Auto Sensor Housing Products CNC Machining, Our Company policy is "quality first, to be better and stronger, sustainable development" . Our pursuit goals is "for society, customers, employees, partners and enterprises to seek reasonable benefit". We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

Hot Products

Auto Waterproof Rubber Parts Vacuum Casting

We frequently vacuum cast rubber auto waterproof parts for custom seals and gaskets, but there is a wide variety of hardness’s available. Anything from the softness of a jelly baby right through to the hardness of a car tyre (Shore 30 – 95A hardness) The level of detail matches that of an injection moulded part.The following is about Auto Waterproof Rubber Parts Vacuum Casting.Mobile Phone Housing Products Vacuum Casting

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about mobile phone housing products vacuum casting.Laser Cutting Aluminium Sheet Metal Parts

To cut metal using a laser, a focused laser beam is directed at the material, which is then either melted, burned, vaporized, or blown away by a jet of gas. This cutting method leaves a sleek edge with high quality and a smooth finish.

Compared to mechanical cutting methods, a laser is easier to work with and there is a reduced possibility of contamination. Laser cutting is also more precise than mechanically cutting since the laser cannot wear down. Furthermore, since lasers use localized heat, there is less chance of warping.The following is about Laser Cutting Aluminium Sheet Metal Parts.Low Volume Production Military Parts Vacuum Casting

Vacuum casting is a low-cost but reliable method for making a small number of high-quality prototypes based on a master model. This method is ideal for rapid prototyping used in engineering testing, proof-of-concept and display demos. On superior prototype, we have a dedicated team of mold makers who are experts at creating vacuum casting molds for many years.The following is about Low Volume Production Military Parts Vacuum Casting.Mechanical Liquid Urethane Resin Parts Vacuum Casting

Vacuum casting services is a type of rapid prototyping technology. It is used for producing a photocopy of the original product in a vacuum state, and then use (PU, transparent PU, POM-like, ABS) and other materials to cast the same copy as the product prototype.

Vacuum casting services are suitable for the customer who requires several sets of rapid prototype parts, which significantly reduces the cost and development time.The following is about Mechanical Liquid Urethane Resin Parts Vacuum Casting.Brass Aerospace Parts CNC Machining

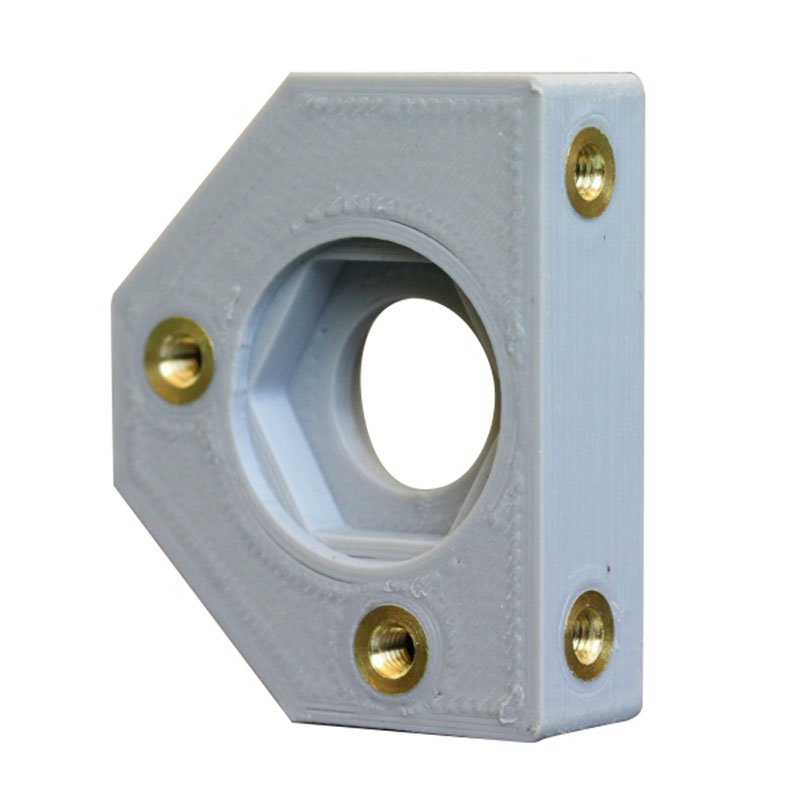

Brass Aerospace Parts CNC Machining have several key advantages compared to machining other materials. Brass turned and machined parts and components are durable, cost-efficient, and even create a tighter seal for fittings. In addition, brass machining and turning parts have a high heat and corrosion resistance! More importantly, Shbury’s brass machined parts are easy to machine and join, and made to your specifications and standards!