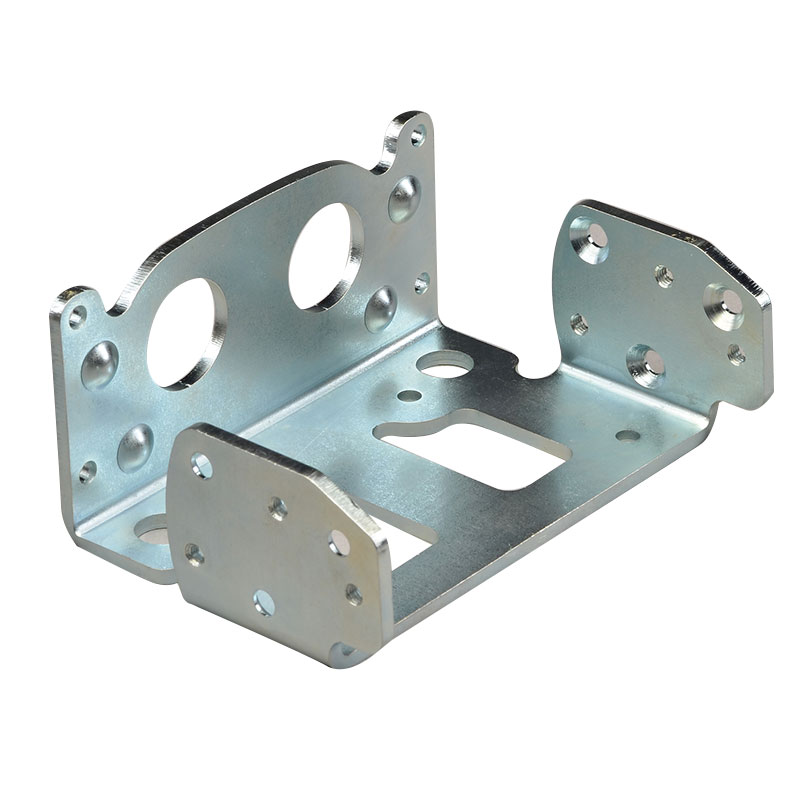

China Galvanized Sheet Bending Parts Manufacturers, Suppliers, Factory

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for Galvanized Sheet Bending Parts,Galvanized Metal Bending Parts and Galvanized Sheet Metal,Metal Sheet Forming Steel Bending Parts Bending Steel Plate,Galvanized Sheet Bending Equipment Metal Parts Sheet Metal,CNC Bending Galvanized Sheet Metal Fabrication Parts, In a word, when you choose us, you choose a ideal existence. Welcome to visit our factory and welcome your get! For even further inquiries, remember to usually do not hesitate to make contact with us.

Galvanized Sheet Bending Parts, We adopt advanced production equipment and technology, and perfect testing equipment and methods to ensure our product quality. With our high-level talents, scientific management, excellent teams, and attentive service, our products are favored by domestic and foreign customers. With your support, we will build a better tomorrow!

Hot Products

Plastic Electronic Products Rapid Prototypes

Do you require quick, economic plastic prototypes with production-like material properties? Vacuum casting in silicone molds is the method that you need. Due to the low die costs, vacuum casting is particularly attractive as an economical secondary procedure for the reproduction of models in small batches.The following is about Plastic Electronic Products Rapid Prototypes.Stainless Steel Passivating Mechanical Rapid Prototypes

Stainless steel refers to steel that is resistant to weak corrosive media such as air, steam, water, and chemically etched media such as acid, alkali, salt, etc., also known as stainless acid-resistant steel. In practical applications, steel that is resistant to weak corrosive media is often referred to as stainless steel, while steel that is resistant to chemical media is referred to as acid-resistant steel. Due to the difference in chemical composition between the two, the former is not necessarily resistant to chemical media corrosion, while the latter generally has rust.The following is about Stainless Steel Passivating Mechanical Rapid Prototypes.Medical Y Joint Connector CNC Turning

Joint Connectors, including the Joint Connector Nuts, Joint Connector Blots, Joint Connector Screws, are mechanical connectors which used to link between two structures, connect parts or components together similar to fasteners. In Mechanical industry, the assembly of any equipment and machine is inseparable from the joint connecter parts, so connectors in different materials (brass, steel, aluminum, alloy, plastic and other metal) are mass-produced to meet different industrial needs. To meet the high quality, sturdy and precise production standards, CNC machining service for Joint Connectors are applied.The following is about Medical Y Joint Connector CNC Turning.3D Printing Electronic Products Rapid Prototypes

Consumers have come to expect periodic releases of ever-more advanced electronics. From smartphones to smart home systems and wearables, new consumer products require significant evaluation and testing before they hit the market. Before moving to mass manufacturing, these new products require rigorous testing for quality, functionality, and user experience.

With new consumer product upgrade and release cycles becoming tighter, electronics designers need a solution that helps reduce the time involved in each R&D and prototyping cycle. By far, the most time-consuming and least productive portion of R&D is repetitive design, build, and test cycles.

Rapid prototyping with traditional manufacturing processes is anything but fast, so designers need a real solution for true rapid prototyping. This illustrates the value of 3D printing in consumer electronics development and prototyping; designers can quickly create fully-functional electronics in a matter of hours rather than days, and this can be done in-house. Designers can innovate more often, quickly test functionality, and implement redesigns before manufacturing at scale. The following is about 3D Printing Electronic Products Rapid Prototypes.Computer Housing Products CNC Machining

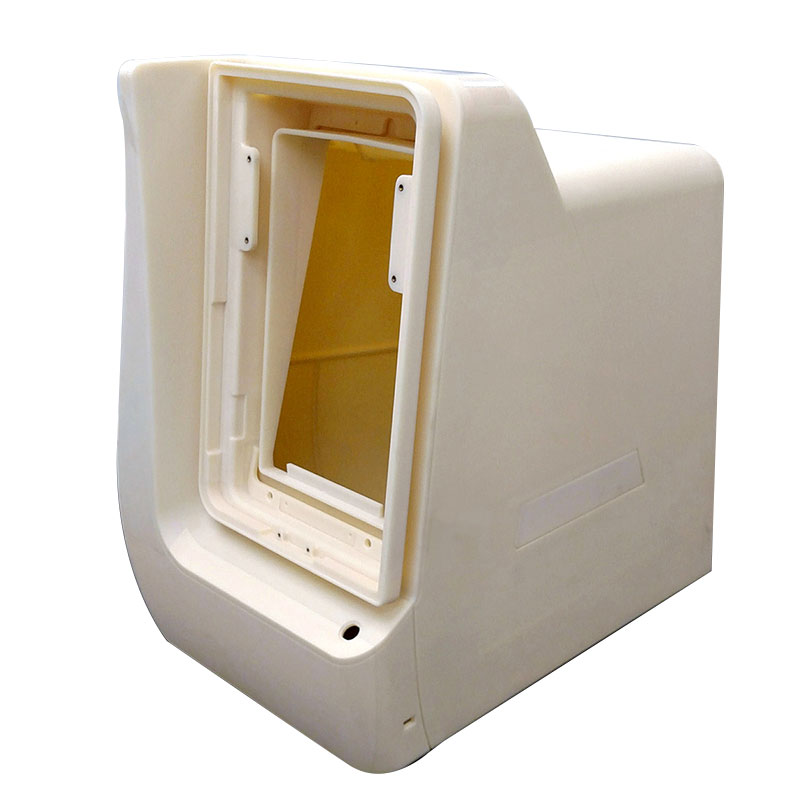

The following is about Computer Housing Products CNC Machining.CNC Machining 4 axis Aluminium Anodizing Parts

CNC Machining 4 axis Aluminium Anodizing Parts:we are specialized manufacturers from China, Aluminum Block, Cnc Milling Machining Parts suppliers/factory, wholesale high-quality products of Aluminum Cnc Machining Parts R & D and manufacturing, we have the perfect after-sales service and technical support. Look forward to your cooperation!