China Laser Cutting Auto Products Rapid Prototypes Manufacturers, Suppliers, Factory

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate within our success for Laser Cutting Auto Products Rapid Prototypes,Laser Cutting Auto Components Rapid Prototypes, For additional information and facts, please speak to us as quickly as possible!

Laser Cutting Auto Products Rapid Prototypes, Welcome to visit our company and factory, there are various solutions displayed in our showroom that will meet your expectation, meanwhile, if you are convenient to visit our website, our sales staff will try their efforts to deliver you the best service

Hot Products

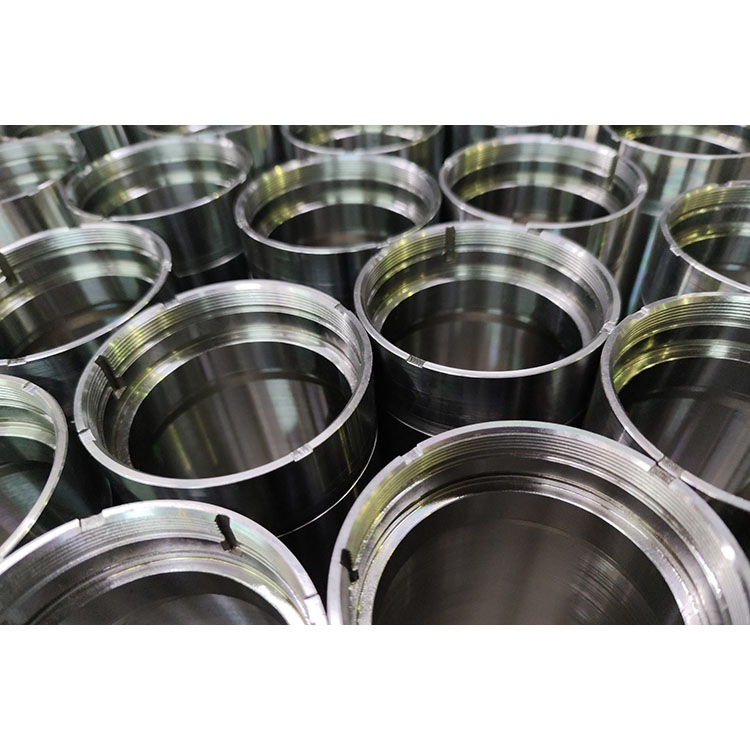

Stainless Steel Passivating Mechanical Rapid Prototypes

Stainless steel refers to steel that is resistant to weak corrosive media such as air, steam, water, and chemically etched media such as acid, alkali, salt, etc., also known as stainless acid-resistant steel. In practical applications, steel that is resistant to weak corrosive media is often referred to as stainless steel, while steel that is resistant to chemical media is referred to as acid-resistant steel. Due to the difference in chemical composition between the two, the former is not necessarily resistant to chemical media corrosion, while the latter generally has rust.The following is about Stainless Steel Passivating Mechanical Rapid Prototypes.Robotic Mechanical Parts CNC Machining

Firstly, parts for robotic applications often have a requirement to be strong, tough and lightweight. Materials such as aluminium have ideal characteristics and can easily be machined using CNC Machining.

Similarly POM (also known as Delrin and Acetal) is commonly used for robotic mechanical cnc machining parts. Easy to machine, it is known for its low friction, high stiffness and superior dimensional stability. As a low-cost plastic, it is also a very economical option.The following is about robotic mechanical parts CNC machining.Airframe Plastic Parts Vacuum Casting

Advantages of Vacuum Casting Technology Possibility of casting parts of complicated shapes, thin-wall parts or parts with negative bevels. Production of small series of prototype or final parts (from dozens up to hundreds of pieces). Favourable production costs in comparison with plastic injection moulding – the production of metal moulds is unnecessary. Fast production – a matter of days. The accuracy of production is comparable with the accuracy of parts manufactured by plastic injection moulding. A wide range of possibilities for final surface treatment.The following is about Airframe Plastic Parts Vacuum Casting.PEEK Auto Parts Rapid Prototyping

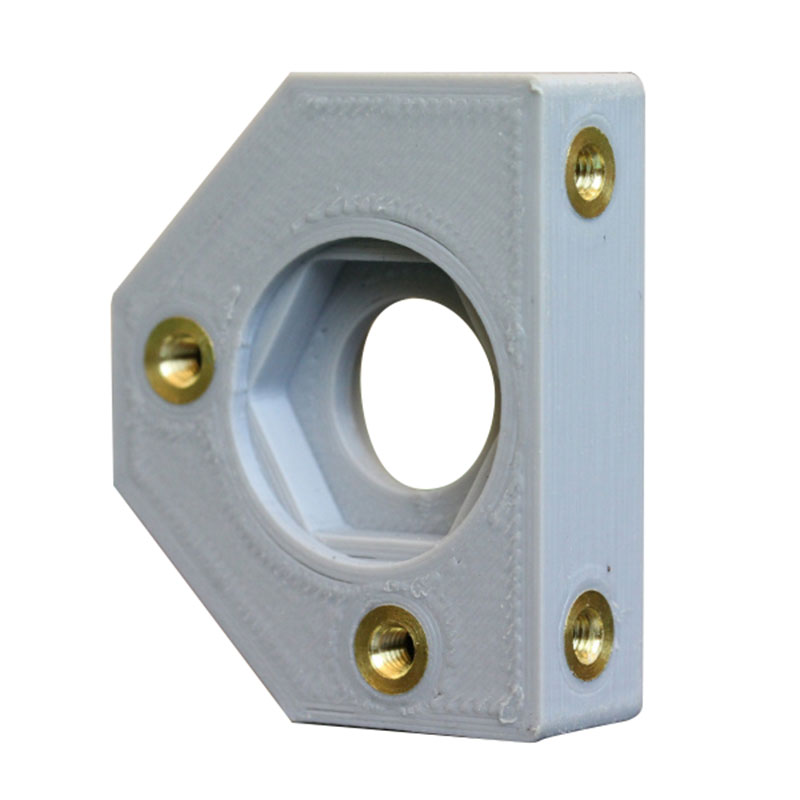

The following is about PEEK Auto Parts Rapid Prototyping.Brass Inserts Plastic Electronic Products Vacuum Casting

Shbury has a fully equipped Vacuum Casting suite with multiple vacuum casting machines. We also have 3D printing facilities which are used for producing the master pattern. For best quality, we use high definition SLA models.The following is about Brass Inserts Plastic Electronic Products Vacuum Casting.Titanium Aerospace Parts CNC Machining

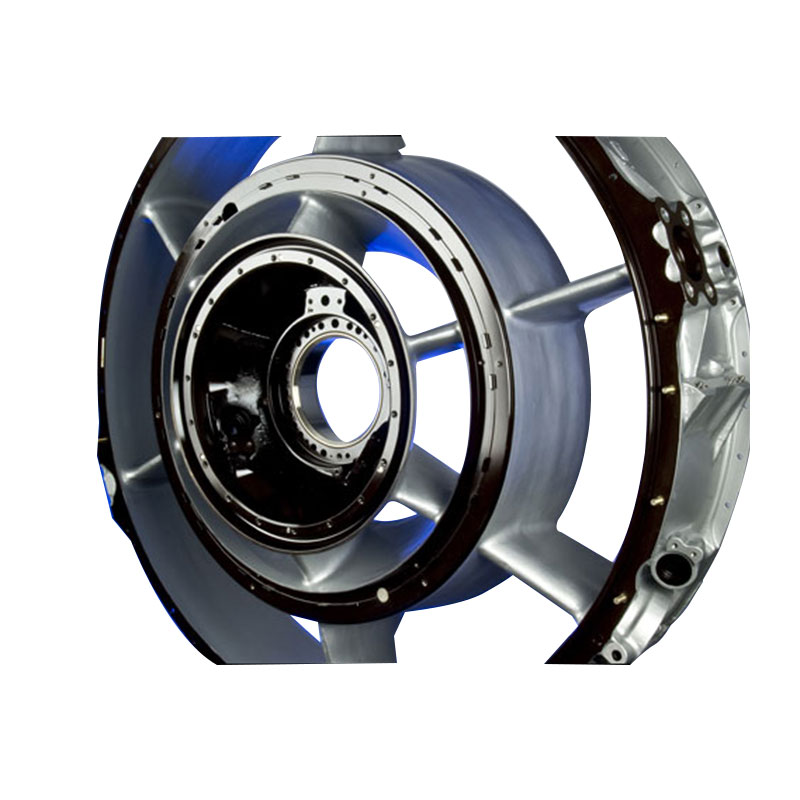

Our high volume components can withstand the intense pressures and various challenges of the Aerospace industry. Common components that we machine for the Aerospace industry include shafts, turbine disks, impellers, and more.The following is about titanium aerospace parts CNC machining.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy