China Precision Aerospace Products CNC Machining Manufacturers, Suppliers, Factory

With our excellent management, strong technical capability and strict quality control system, we continue to provide our clients with reliable quality, reasonable prices and excellent services. We aim at becoming one of your most reliable partners and earning your satisfaction for Precision Aerospace Products CNC Machining,Precision Aerospace Parts CNC Milling,Precision Aerospace Components CNC Machining, Welcome your browsing and any your inquires,sincerely hope we are able to have chance to cooperate with you and we will build-up extensive effectively company marriage along with you.

Precision Aerospace Products CNC Machining, We supply OEM services and replacement parts to meet the varying needs of our customers. We supply competitive price for quality goods and we are going to make certain your shipment is handled quickly by our logistics department. We sincerely hope to have the opportunity to meet with you and see how we can help you further your own business.

Hot Products

Stainless Steel Passivating Mechanical Rapid Prototypes

Stainless steel refers to steel that is resistant to weak corrosive media such as air, steam, water, and chemically etched media such as acid, alkali, salt, etc., also known as stainless acid-resistant steel. In practical applications, steel that is resistant to weak corrosive media is often referred to as stainless steel, while steel that is resistant to chemical media is referred to as acid-resistant steel. Due to the difference in chemical composition between the two, the former is not necessarily resistant to chemical media corrosion, while the latter generally has rust.The following is about Stainless Steel Passivating Mechanical Rapid Prototypes.Mechanical Connectors Parts CNC Turning

Mechanical Connectors Parts, including the Joint Connector Nuts, Joint Connector Blots, Joint Connector Screws, are mechanical connectors which used to link between two structures, connect parts or components together similar to fasteners.The following is about Mechanical Connectors Parts CNC Turning.Auto Parts Vacuum Urethane Casting

Vacuum casting technology offers a wide variety of materials to facilitate the creation of cast urethane parts, typically for functional test, pre-production evaluation and low volume production. Cast auto urethane parts are quick and inexpensive without the need to invest any metal tooling when quantities are only dozens of short runs, and can be delivered within weeks in most instances. The following is about Auto Parts Vacuum Urethane Casting.Auto Transmission Parts CNC Turning

The following is about Auto Transmission Parts CNC Turning.Top Grade Medical Joint Connector CNC Turning

As one of the Top Supplier of CNC Turning service in China, Shbury has the right advanced machines and technical team to manufacture your Joint Connector economically and to your precise specifications, covering OME production for nuts, blots, screws and other Joint Connector parts.The following is about Top Grade Medical Joint Connector CNC Turning.Aluminum Sheet Metal Bending Stamping Fabrication

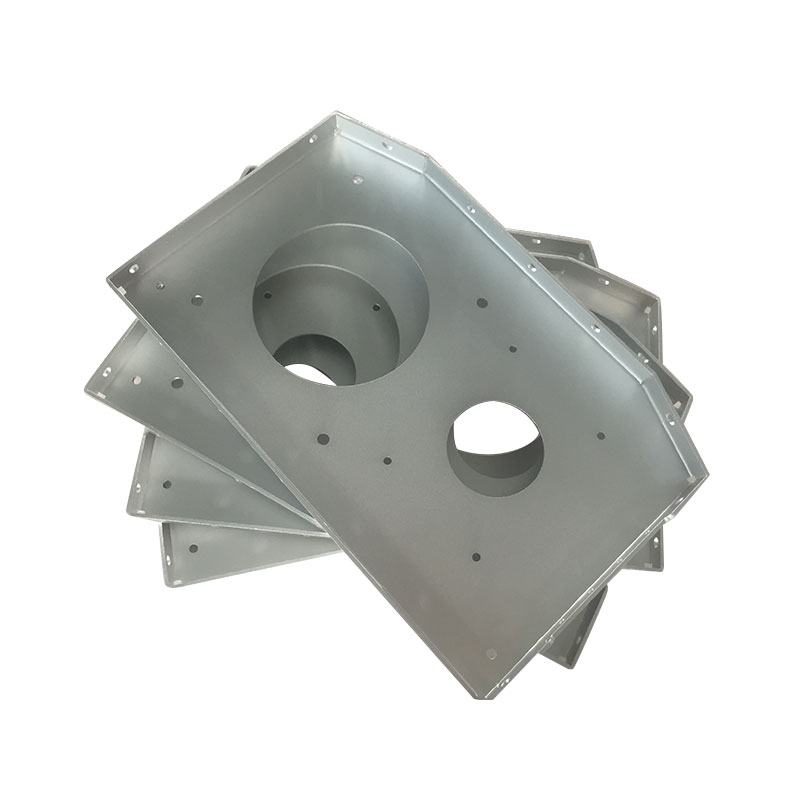

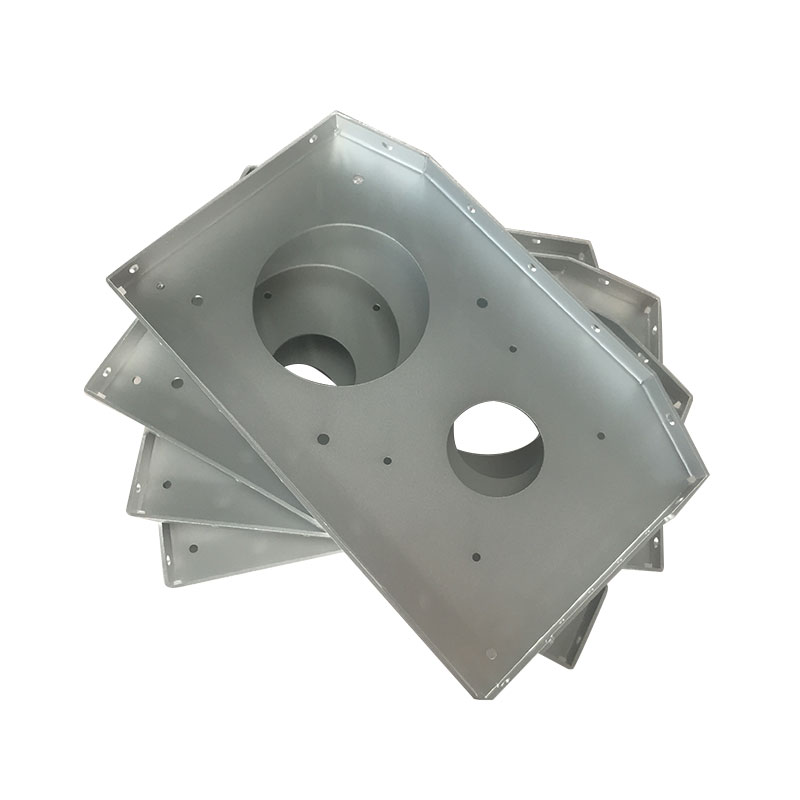

High quality Aluminum Sheet Metal Bending Stamping Fabrication made in China. Guoye Optoelectronics is Aluminum Sheet Metal Bending Stamping Fabrication manufacturer and supplier in China.