China Tight Tolerance Military Parts CNC Milling Manufacturers, Suppliers, Factory

Our company promises all users of the first-class products and the most satisfying post-sale service. We warmly welcome our regular and new customers to join us for Tight Tolerance Military Parts CNC Milling,Tight Tolerance Military Products CNC Machining,Tight Tolerance Military Components CNC Machining, we could solve our customer problems asap and do the profit for our customer. For those who need excellent company and top quality , pls choose us , thanks !

Tight Tolerance Military Parts CNC Milling, Our mission is "Provide Merchandise with Reliable Quality and Reasonable Prices". We welcome customers from every corner of the world to contact us for future business relationships and achieving mutual success!

Hot Products

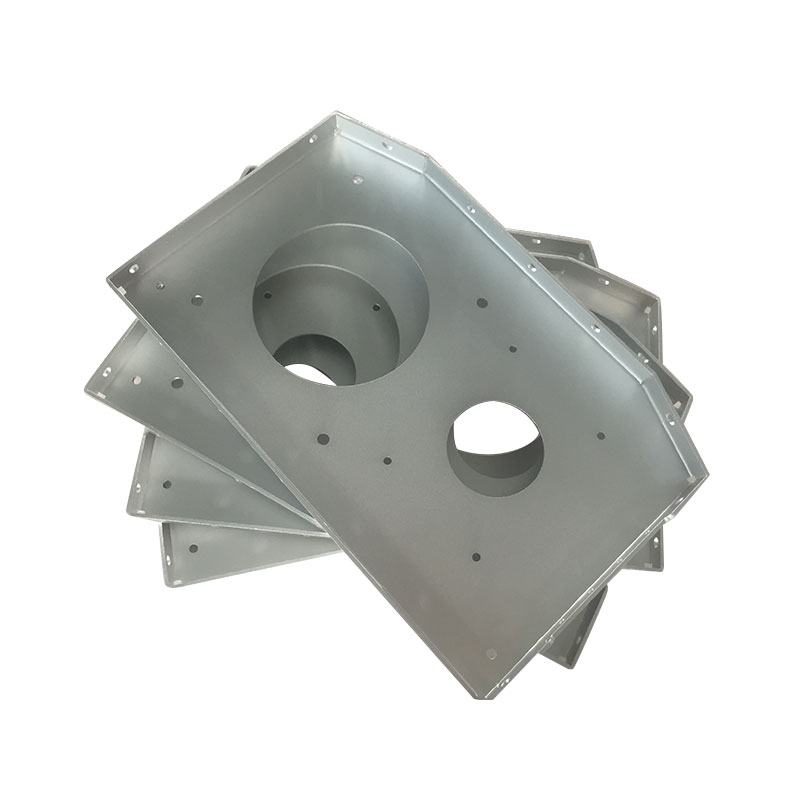

Galvanized Steel Sheet Metal Bending Parts

Galvanized steel sheet metal bending parts or galvanealed steel, which is galvanized then annealed.

Galvanization is the process of applying a protective zinc coating to steel in order to prevent rust and corrosion. Annealing is a heat treatment process that alters the microstructure of a material to change its mechanical or electrical properties, typically reducing the hardness and increasing the ductility for easier fabrication.Precision Machined Sheet Bending Parts

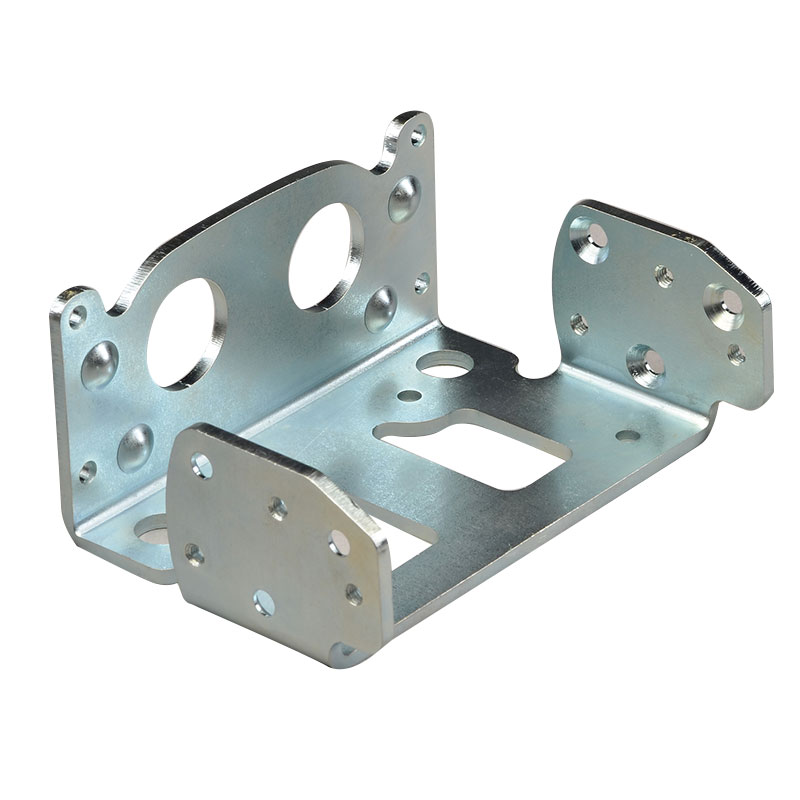

Hot Selling Low Price Precision Machined Sheet Bending Parts. Guoye Optoelectronics is Precision Machined Sheet Bending Parts manufacturer and supplier in China.Medical Device Plastic Housing Vacuum Casting

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about medical device plastic housing vacuum casting.Silicone Buttons Products Vacuum Casting

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal. But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about silicone buttons products vacuum casting.Indirectly Human Medical Device Parts CNC Machining

The following is about Indirectly Human Medical Device Parts CNC Machining.Electronic Hookah Nozzle Products CNC Turning

The following is about Electronic Hookah Nozzle Products CNC Turning.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy