China Auto Waterproof Rubber Products Vacuum Casting Manufacturers, Suppliers, Factory

"Control the standard by the details, show the power by quality". Our firm has strived to establish a extremely efficient and stable employees crew and explored an effective excellent command method for Auto Waterproof Rubber Products Vacuum Casting,Auto Waterproof Rubber Components Vacuum Casting, We will do our best to meet your requirements and are sincerely looking forward to developing mutual beneficial business relationship with you!

Auto Waterproof Rubber Products Vacuum Casting, Our staffs are rich in experience and trained strictly, with professional knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to provide the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we will develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

Hot Products

2021 New Design Red Anodizing Aluminum CNC Machining Service

2021 New Design Red Anodizing Aluminum CNC Machining Service, Aluminum CNC parts are the all-time preferred auto components for auto spares and other industries, not just because they are very lightweight and attractive, but also because aluminum has many additional properties like its durability and its ease of installation. Under specific conditions, aluminum can be made very corrosion resistant. The fact that this metal can be cheaply obtained makes it the most economical option for the manufacturing industry. Aluminum parts anodizing is a process that makes aluminum the ultimate metal for a lot of interior and exterior building purposes and designs. Aluminum can also be molded into different shapes to form various aluminum parts.Computer Housing Products CNC Machining

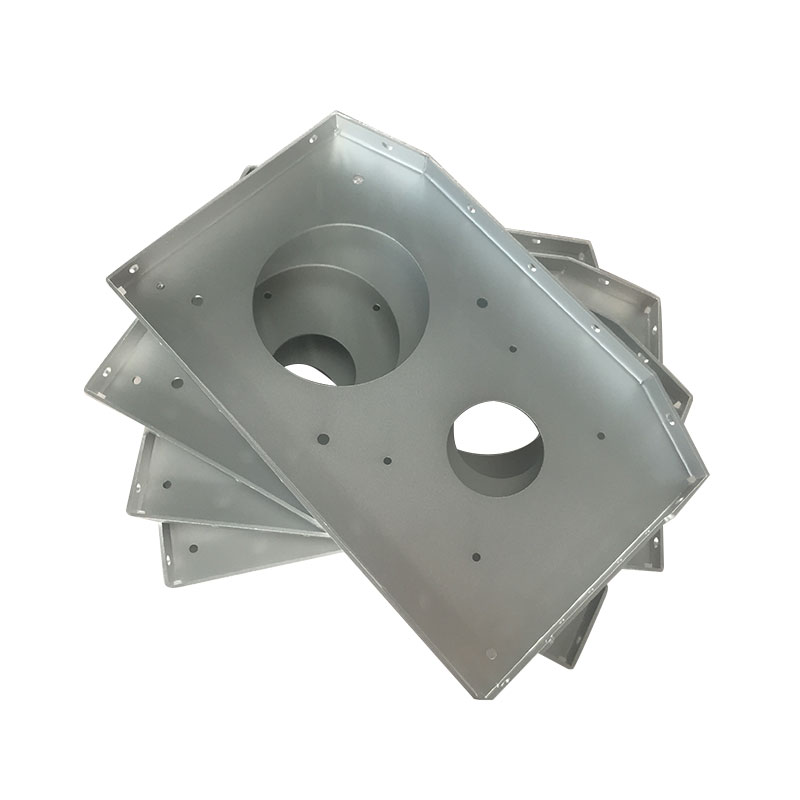

The following is about Computer Housing Products CNC Machining.Airframe Plastic Parts Vacuum Casting

Advantages of Vacuum Casting Technology Possibility of casting parts of complicated shapes, thin-wall parts or parts with negative bevels. Production of small series of prototype or final parts (from dozens up to hundreds of pieces). Favourable production costs in comparison with plastic injection moulding – the production of metal moulds is unnecessary. Fast production – a matter of days. The accuracy of production is comparable with the accuracy of parts manufactured by plastic injection moulding. A wide range of possibilities for final surface treatment.The following is about Airframe Plastic Parts Vacuum Casting.E-cigarette Aluminium Tube Products CNC Turning

The following is about E-cigarette Aluminium Tube Products CNC Turning.Aluminium Electronic Products Rapid Prototypes

Aluminum alloy is widely used in the industry. It is low in density, high in strength, excellent in elasticity, processability and welding characteristics. It also features good corrosion resistance, high toughness, and deformation after manufacturing.

Aluminum alloy molding can help discover potential flaws early in the product development stage, saving money in the long-run and minimizing production times. Aluminum alloy rapid prototype helps generate accurate product test data.The following is about Aluminium Electronic Products Rapid Prototypes.Vacuum Casting Prototype for Mobile Phone Housing

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about mobile phone housing products vacuum casting.