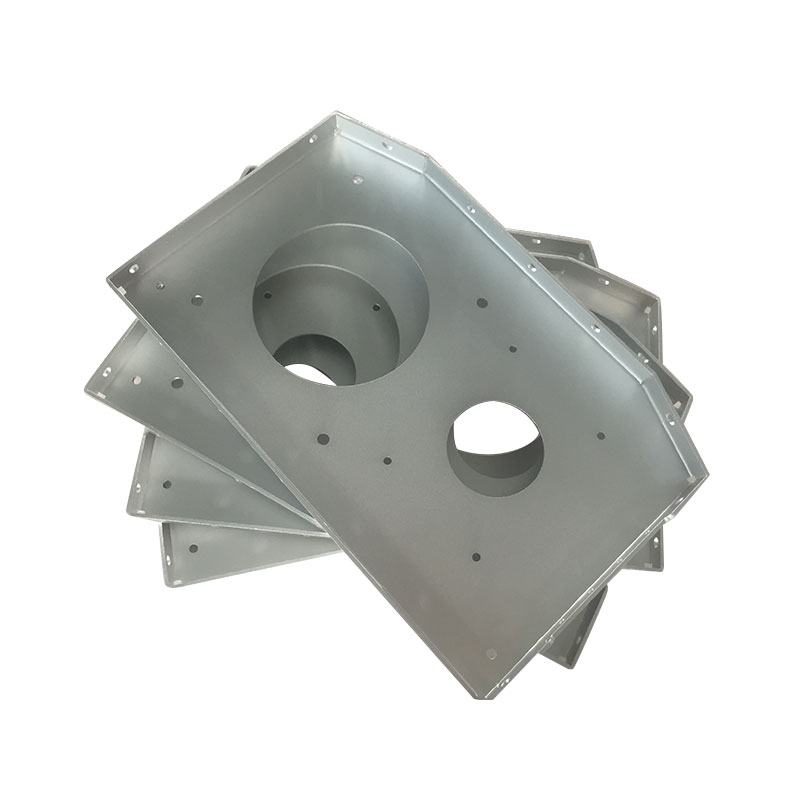

China CNC Machining Aluminum anodizing Plate Parts Manufacturers, Suppliers, Factory

To be a result of ours specialty and repair consciousness, our corporation has won a good popularity amid consumers everywhere in the environment for CNC Machining Aluminum anodizing Plate Parts,Eco-friendly CNC Machining Aluminum anodizing Plate Parts, We warmly welcome prospects, organization associations and mates from everywhere in the earth to get in touch with us and request cooperation for mutual benefits.

CNC Machining Aluminum anodizing Plate Parts, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to offer our clients sincerely with qualified solutions, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

Hot Products

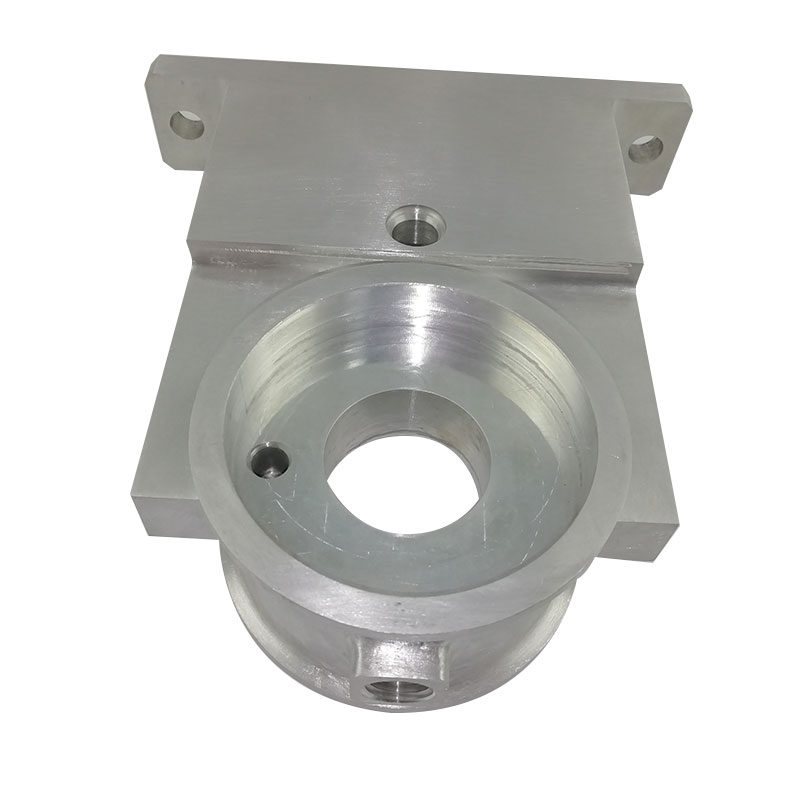

High Precision Medical Device Parts CNC Machining

High Precision Medical Device Parts CNC Machining Shbury is a trusted supplier of medical device parts. Shbury is committed to improving the quality of life for patients and medical staff throughout the industry. Backed by over 10 years of CNC experience, our skilled machinists are able to create a custom medical component with the greatest accuracy possibleMedical Device Plastic Housing Vacuum Casting

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about medical device plastic housing vacuum casting.Airframe Plastic Parts Vacuum Casting

Advantages of Vacuum Casting Technology Possibility of casting parts of complicated shapes, thin-wall parts or parts with negative bevels. Production of small series of prototype or final parts (from dozens up to hundreds of pieces). Favourable production costs in comparison with plastic injection moulding – the production of metal moulds is unnecessary. Fast production – a matter of days. The accuracy of production is comparable with the accuracy of parts manufactured by plastic injection moulding. A wide range of possibilities for final surface treatment.The following is about Airframe Plastic Parts Vacuum Casting.Motor Shafts Parts CNC Turning

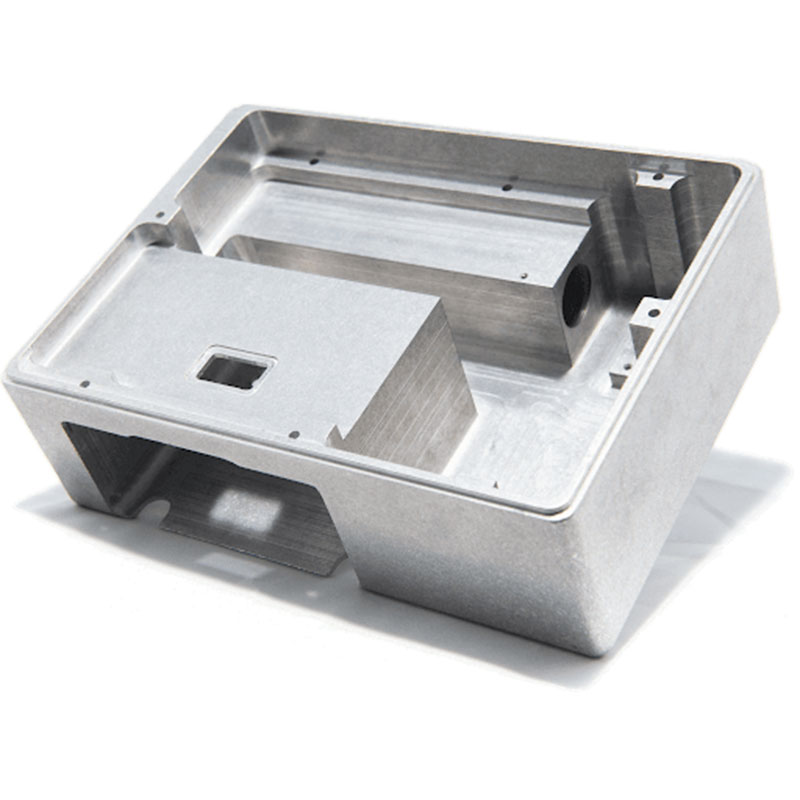

The following is about Motor Shafts Parts CNC Turning.Highest Level Military Parts Cnc Machining

CNC machining service provides a significant manufacturing solution for CNC military parts of a diversity of military and defense equipment, like army equipment, navy equipment, military aircraft, military vehicles, ordnance, ship & submarines, air force equipment, marine corps equipment, coast guard equipment, weapons, etc. To meet the high demands and high standard of military instruments, online Highest Level Military Parts CNC Machining CNC machining , advanced processing technique and sophisticated devices to ensure the high efficiency, high precision, tight tolerance, long service life and outstanding performance of the products.Agricultural Machinery Parts CNC Machining

Agricultural Industry is ever evolving, one thing hasn’t changed at all: agricultural equipment component failure can have major implications for a project or a crop. Since agriculture parts are large and complex, all agriculture parts which are used on the agricultural equipment must be carefully worked with high demands of technical specifications including tight tolerance, ultra-high precision specifications, and the best durable materials to ensure the machines and equipment’ service life. So customized CNC machining services for agricultural equipment is very important in the agriculture parts manufacturing field, also custom CNC agricultural parts can make your equipment more competitive in the market.The following is about agricultural machinery parts CNC machining.