China Cold Carbon Steel Sheet Metal Components Manufacturers, Suppliers, Factory

We know that we only thrive if we will guarantee our combined cost competiveness and high-quality advantageous at the same time for Cold Carbon Steel Sheet Metal Components,Cold Carbon Steel Sheet Metal Products, We glance ahead to supplying you with our goods from the near long run, and you'll find our quotation is very acceptable plus the top quality of our goods is quite outstanding!

Cold Carbon Steel Sheet Metal Components, Upon today, we have customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to provide the highest quality products with best price. We are looking forward to doing business with you.

Hot Products

Aluminium Electronic Products Rapid Prototypes

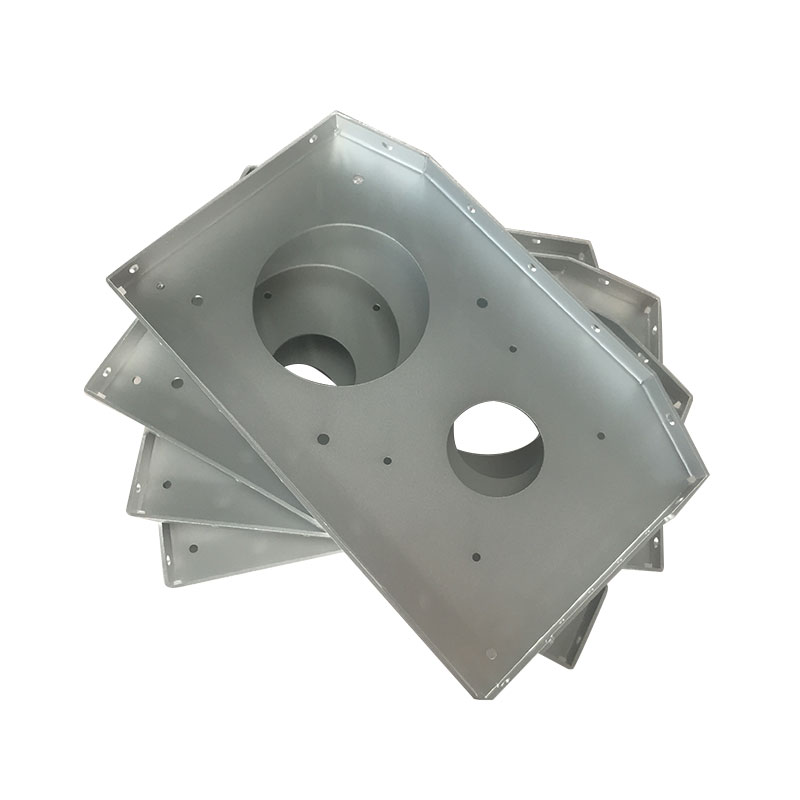

Aluminum alloy is widely used in the industry. It is low in density, high in strength, excellent in elasticity, processability and welding characteristics. It also features good corrosion resistance, high toughness, and deformation after manufacturing.

Aluminum alloy molding can help discover potential flaws early in the product development stage, saving money in the long-run and minimizing production times. Aluminum alloy rapid prototype helps generate accurate product test data.The following is about Aluminium Electronic Products Rapid Prototypes.Auto Parts Powder Coating Rapid Prototype

Powder Coating is most commonly used in the industrial sector for both (Low Volume and High Volume) Mass Production Factories such as CNC Machine Shops and Sheet Metal Fabrication Facilities. The Powder Coating material is a composite mixture of fine powderized paint pigments and fine powderized plastic particles. The fine powderized plastic particles are comprised of either (thermoplastics or thermoset plastics) such as Polyester and Epoxy. When discharged through the Powder Coat Paint Gun, the particles are ionized via an electrical coil. The positively charged ions assist the powder in the coating process as it is attracted to the negatively charged part.The following is about Auto Parts Powder Coating Rapid Prototype.Stainless Steel Aerospace Parts CNC Machining

CNC machinery can operate with even the highest-quality metals, creating parts that can withstand the intense pressures and temperatures inherent to aerospace applications,especially stainless steel aerospace parts CNC Machining. We at Shbury are deeply aware of the many benefits CNC machining brings to the aerospace manufacturing field, which is why we’ve made this manufacturing technique central to our production processes.Stainless Steel Passivating Mechanical Rapid Prototypes

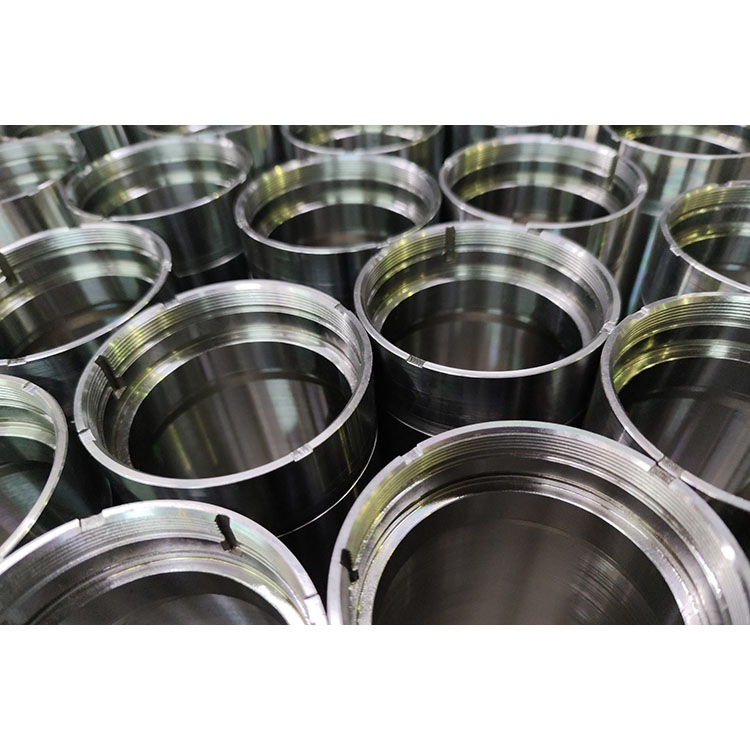

Stainless steel refers to steel that is resistant to weak corrosive media such as air, steam, water, and chemically etched media such as acid, alkali, salt, etc., also known as stainless acid-resistant steel. In practical applications, steel that is resistant to weak corrosive media is often referred to as stainless steel, while steel that is resistant to chemical media is referred to as acid-resistant steel. Due to the difference in chemical composition between the two, the former is not necessarily resistant to chemical media corrosion, while the latter generally has rust.The following is about Stainless Steel Passivating Mechanical Rapid Prototypes.Carbon Steel Military Parts CNC Turning

Shbury specializes in precision CNC parts and components that match military standards. We can provide complex machined parts at close tolerances along with accurate supporting documentation. The following is about Carbon Steel Military Parts CNC Turning.PEEK Auto Parts Rapid Prototyping

The following is about PEEK Auto Parts Rapid Prototyping.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy