China High Precision CNC Mobile Phone Metal Housing Manufacturers, Suppliers, Factory

Our goal is to satisfy our customers by offering golden service, good price and high quality for High Precision CNC Mobile Phone Metal Housing,Cast Iron Motor Housing by Casting, Our products are strictly inspected before exporting , So we gain a good reputation all over the world. We looking forward to cooperation with you in the future.

High Precision CNC Mobile Phone Metal Housing, Our goods are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we have been focusing on the production process. We have now got high praise by partner. We're looking forward to establishing business relationship with you.

Hot Products

Medical ECG Device Shell CNC Machining

The following is about Medical ECG Device Shell CNC Machining.Brass Aerospace Parts CNC Machining

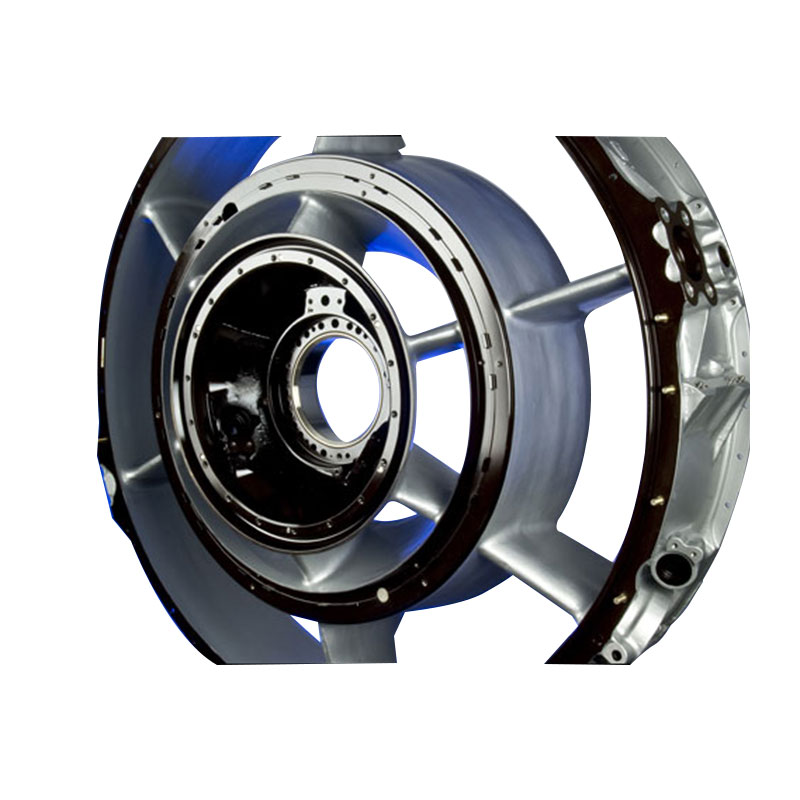

Brass Aerospace Parts CNC Machining have several key advantages compared to machining other materials. Brass turned and machined parts and components are durable, cost-efficient, and even create a tighter seal for fittings. In addition, brass machining and turning parts have a high heat and corrosion resistance! More importantly, Shbury’s brass machined parts are easy to machine and join, and made to your specifications and standards!Mobile Phone Housing Products Vacuum Casting

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about mobile phone housing products vacuum casting.Medical X-ray Housing Rapid Prototypes

Optometry device cover for medical deviceThe design process for new or improved medical devices, such as catheters, stents, fluid administration systems, drug delivery systems, chemotherapy tips, syringes, cardio-vascular devices, vascular access devices, etc. includes the important step of producing, examining, and testing a physical medical prototype. Engineers and designers benefit from having a medical prototype to sample its size and get an idea of a its form, fit, and feel.The following is about Medical X-ray Housing Rapid Prototypes.Medical Device Liquid Silicone Vacuum Casting Parts

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about Medical Device Liquid Silicone Vacuum Casting Parts.Auto Throttle Control Shafts Parts CNC Machining

The following is about Auto Throttle Control Shafts Parts CNC Machining.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy